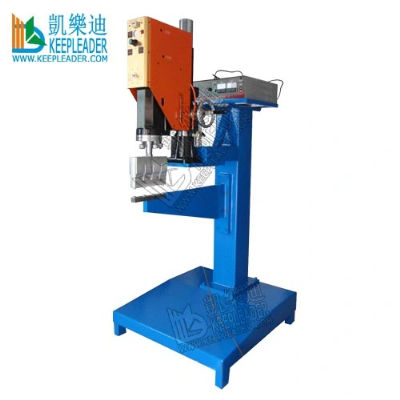

Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder of

Coroplast Boards Soldering Turnover Totes Ultrasound

WeldersCorflute Sheet Welding PP Corrugated Box Ultrasonic Spot

Welder obtains recognition among competitors with its

particular advantages belowUsable weld throat depth up to 500mm are

standardStable pedestal counted with robust column to achieve max

loading height 1300mmGenerator mounted next to press for convenient

operator viewing and setupStrong, welded steel extension arm with

universal fixture padFlexible mounting slot to install fixture for

versatile size in productionWelding depth, power, time and pressure

all are adjustable Product Description Corflute Sheet

Welding PP Corrugated Box Ultrasonic Spot WelderCharactersIC

circuit precision control, automatic overload protection

systemadopting digital switch, 1/100 precision re-set

controladjustable horizontal level, easy control welding hornhigh O

transducer, optimized output Have resonant frequency when the load,

unload, without adjustment for the frequency of welding horn

Square column and column airframe structure is optional, the

straight line guide bearing, the precise matching device Using the

turbine rotation to adjust the machine movement, which is better

than normal Adopting Japan HuangPai brand alloy steel to keep

frequency strong and stable Celebrate itself durability for

adopting USA aviation standard 7075 and 6064 Aluminum

alloy the electronic components are imported from Italy,

Japan, American, South Korean, Taiwan and actall in one high

capacity machine, applied for high precision of welding work

pieceAutomatic protective device, which is optionalhigh-power

machine, which is applied for Large work pieceBasic

parameterModelKLC-2615LInput power2600WFrequency15KHZInput

voltage 110V/220VHorn Stroke distance70mmOscillation

systemAuto-stimulatingOutput

time0.01-99SPressure Pressure bound 1-7barWelding

area 200mmCompressor2HPNet weight 100kg MFR:

KEEPLEADER™ have modified and designed Corflute Sheet

Welding PP Corrugated Box Ultrasonic Spot Welder for our

customers' unique and special requirements, please contact

KEEPLEADER™ for updated details Machine

Uses Corflute Sheet Welding PP Corrugated Box Ultrasonic

Spot Welder integrates robust column with stable pedestal to

form a loading depth in corrugated box making, ultrasonic welding

machine stands on the top extended frame to suffice to spot bonding

depth, the finished corrugated plastic box is a new type of

turnover box in the logistics packaging industry, people also call

it correx box, corflute box or coroplast box, it also can be called

corrugated plastic bin, corrugated plastic totes and corrugated

plastic containers Contact Us Corflute Sheet Welding PP

Corrugated Box Ultrasonic Spot Welder is only of ultrasonic

welding technical solution in corflute box making, we, keepleader

is not only a professional manufacturer but also a reliable

cooperator to work with you in improving your productivity at an

affordable pricing, please contact us to find what more we can do

for you/* March 10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Corflute Sheet Welding PP Corrugated Box Ultrasonic Spot Welder of Coroplast Boards Soldering Turnover Totes Ultrasound Welders

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup