Techemer Composites is a professional provider of special and

customized material solution for medium and low speed rotary

devices, dedicating ourselves to provide the best services to

fulfill the needs of various industries such as aerospace,

earthquake-proof foundation, machinery, offshore oil and gas, power

generation, ship, transportation, water pump.Water acts as a

lubricant, avoiding water contamination resulting from leakages of

lubricant grease;Elastic-plastic alloy bonded with lubricative

particles withstands specific impulsive loads, Edge loads, dry

start-up compatible and maintenance-free;Well-balanced friction and

incredible wear resistance dispels wear particles to avoid wearing

the shaft surface;Customized material selections and bearing design

available based on the characteristics and operational conditions

of the devices;ISO 9001:2015 quality management system certified

and a company persistently focusing on the needs of

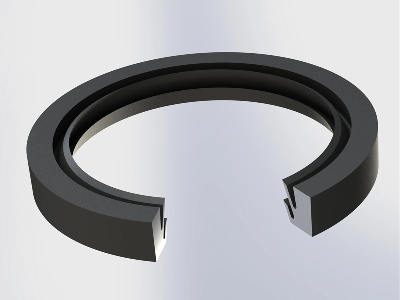

customers.INDRON® seals and gaskets are more durable than

ordinary bearing materials under various operation medium

conditions, such as dry friction, water lubrication (clear water or

water containing sand and shale), oil lubrication and grease

lubrication, etc. and even the operation condition of impulsive

loads. INDRON® oil and gas sealing material has excellent

mechanical properties, good rigidity, toughness, hardness, wear

resistance, small permanent compression set, excellent high and low

temperature resistance, and excellent aging resistance. It is

mainly used to prevent lubricating oil from leaking out or oil mist

overflowing in the oil tank. COMMON GUIDE BEARING

MATERIALSBearing typeINDRON bearingAR bearingCeramic bearingRubber

bearingBabbitt alloy bearingCharacteristicsThe performance is close

thordon, which can use more equipment assembly methods. In addition

to traditional installations by freezing and pressurizing. It can

also be installed by coating reactive thermal polymerization Dx and

cold sticking.Good wear resistance and impact resistance. The

bearing hardness is high; the shaft sleeve is easy to wear; the

temperature difference changes greatly; there will be the risk of

shelling; the price is high.Wear-resistant, heat-resistant,

corrosion-resistant, lubricated by pump circulating water, capable

of dry grinding for a short time, high requirement on accuracy in

processing and assembly, fragile and the most expensive.It has a

long history and mature manufacturing process, featured by wear

resistance, anti-seismic, impact resistance, convenient

assembly/disassembly and low price (only 20% of ceramic bearings

price)Wear resistance and impact resistance require a set of more

complicated sealing and lubricating devices and

mechanisms.Lubricating requirementsClean water can be used for

lubrication or 150s dry start according to the material grades.Dry

start more than 180S without clean water lubrication.It can be

lubricated by pumping medium without special clean water

lubrication.Clean industrial waterGrease lubrication requires a

grease supply lubrication system.Working temperature≤70ºC≥273ºCThe

bearing itself can withstand the temperature of

1,400ºC≤50ºC≤65ºCShort time up to 80ºCApplication siteFor pumping

stations short of clean water or pumping stations requiring

short-term dry friction, hRBR grade is suitable for water quality

with moderate sediment content.Pumping stations without clean water

or pumping stations requiring dry friction of more than

180S.Pumping stations without clean water or pumping stations

requiring short-term dry friction.Extensive application in any

pumping stations with clean water sources.The liquid of the pump

itself cannot be used for bearing lubrication in the pumping

station.Bearing typeINDRON bearingAR bearingCeramic bearingRubber

bearingBabbitt alloy bearing/* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Custom Radial Shaft Seals, Applied in Marine, Pump, and Hydropower Industries

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup