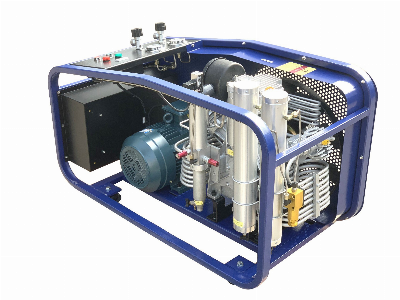

1,Product nameHY-W400 Respirator air pump (high pressure air

compressor)7.5KW 400L/min 30MPa 300Bar Electric Scuba Diving

Breathing Air Compressor Popular high pressure 300bar air

compressor 200 bar for scuba tanks2,Product Picture3,Main

parametersModel:HC-W400Work

pressure:30Mpa Mpa(300bar)Displacement (inhalation

state):400L/min L/minType:W-type layout-three-cylinder

three-stage reciprocating piston

compressionDrive:Electric 380V/50Hz/5.5kw or honda

gasoline engine driveLubrication method:Splash lubrication (food

grade lubricant 750-H2)Cooling method: air coolingControl

method:Automatic shutdownClean air:Primary air filtration,

secondary oil-water separation, secondary classification air

purificationSafety devices:Interval safety valve, pressure

maintenance valve, automatic shutdown system, transmission part

installation protective coverPacking size

(length×width×height):125×70×92cmWeight:190kgInflation speed:It

takes about 10 minutes to fill a 6-liter bottle with 30MpaCertified

product:CE certification, MA test reportPacking List:Manual,safety

inspection report certificate, 2 sets of inflation hoses and

joints, and the machine has built-in food-grade

lubrication.4,Working principleThis product is mass-produced after

design changes and optimizations in accordance with the Italian

model. The final piston adopts a special process, and the piston

ring adopts the Japanese Riken process. Unanimous praise from

users. This product adopts three-cylinder three-stage compression,

splash lubrication, inter-stage safety valve and filter system.

HC-W300 can provide safe compressed air for any industry that needs

high-pressure pure air source, and provide safe compressed air that

meets the requirements of human breathing. This product is

designed, produced and tested and accepted in accordance with the

requirements of GB/T 12929-2008 "Marine High Pressure Piston Air

Compressor"; the air quality meets the EN12021 international

breathing compressor breathing standard; HC-W300 is a kind of air

compression equipment, it will be free 1 kg (1bar/0.1Mpa) of the

air in the state is compressed to a high pressure gas with a gauge

pressure of 300 kg (300bar/30Mpa). The oil and impurities in the

high-pressure air can filter the inhaled air containing fine

particles (PM2.5) to a safety value of less than 10 micrograms,

which meets the standards set by the World Health Organization,

making the exhaust gas clean and tasteless. The personnel provide

highly purified, clean, odorless, safe and reliable compressed

breathing air.5,Product composition and characteristicsStandardized

assembly-mass productionThe machine is equipped with an automatic

shutdown device, the shutdown pressure can be set freely, and it is

equipped with a time running timer to support the maintenance

time;Two gas cylinders can be filled at the same time; (1 bottle is

recommended for filling faster)High-power all-copper core wire

customized motor, stable power output, light starting load;The

protective cover adopts plastic spraying process, which is not easy

to scratch and rust; (some manufacturers use spray paint, which is

low in cost and easy to fall off and rust)Super V-belt, strong

tension, wear-resistant and high-temperature resistant;Shockproof

pressure gauge 0~5800psi/400bar, accurate pressure value;The

reinforced steel plate base is equipped with anti-vibration pads,

so the equipment runs more smoothly;High-strength nylon cooling

fan, better heat dissipation effect;The low pressure adopts red

copper tube, which has better heat dissipation performance, and the

high pressure adopts stainless steel tube to ensure the safety of

output pressure;The rotating parts are equipped with protective

cover devices, and all levels are equipped with safety valves and

automatic shutdown systems to ensure the safety of

operators;Optional motor drive or gasoline engine drive to meet the

gas supply needs under various conditions;Configure precision air

filter (customized wire mesh filter element);2-stage oil-water

separator (standard manual blowdown, optional automatic blowdown)

final classification air purification system (standard manual

blowdown, optional automatic blowdown) two-stage purification,

first removes water, then removes odor;(Most manufacturers use

level 1 mixed filtration to save production costs)The last stage

adopts piston ring technology, and only the piston ring needs to be

replaced when worn;(Most manufacturers do not use the final stage

piston ring process, and need to replace a complete set of pistons

and cylinders after wear, and pay for expensive accessories)The end

adopts a pressure maintenance valve, deep air filtration, and

extends the life of the filter element, and adopts an alloy

aluminum permanent filter element, a replaceable filter element

material, and saves later use costs;(Some manufacturers have no

pressure maintenance valve and use disposable filter elements,

which saves production costs and increases later use costs)The

parts in contact

Related products about Popular High Pressure 300bar Air Compressor 200 Bar for Scuba Tanks

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup