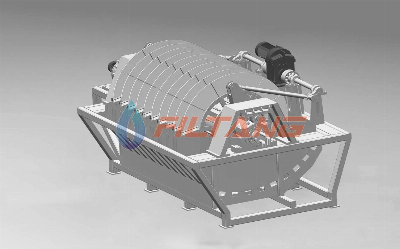

Filtang CVD Disc Vacuum FilterDesign philosophyEnergy saving

and production capacityCeramic flat membrane filter plate group of

microfiltration grade in several circles is mounted on rotor. After

slurry is fed in slurry trench, rotor starts to rotate slowly, the

surface of ceramic flat membrane filter plate soaked in slurry

continually creates increasingly thickening filter cake due to

internal vacuum suction force and end filtration theory, whilst

filtration liquid enters into filtration liquid tank from

deployment pump via internal channels of filter plate. After filter

cake transfers from slurry liquid level, spray device can be used

to wash filter cake, and filter cake continues to be dehydrated

under the effect of vacuum. After reaching appropriate moisture

rate, scraper performs unloading for filter cake at unloading end,

and afterwards filter plate is re-soaked in slurry, starting the

next circle of filtration. After a period of time of operation,

filter plate can be cleaned by adopting back wash, ultrasonic and

low concentration acid.Technique featuresContinuous

operationsFilters applied in multiple industrial fields such as

beneficiation, desulphurization in power plate include TC precision

ceramic filter, CC ceramic filter and so on. Filtang CVD is

developed from TC, and compared to TC model, it upgrades ceramic

filter plate. Working life of the filter plate is 3 times that of

TC model, filtration precision is higher, probability of particle

blockage is decreased, and it is more fitful with filtration of

fine particles. CVD control system automatically configures

rotation of filter disc, and continually performs absorption,

spray, drying, material unloading, and back wash. Operation of the

equipment is simple and easy, equipment shut down and filter plate

maintenance drop substantially compared to TC model, and rare

manual intervention is needed. StructureAutomatic

operationsFiltration stereotype of CVD is new ceramic flat

membrane. The plate membrane combines catalyst materials,

effectively impeding accumulation of colloidal matter on the

surface of membrane and beneficial to regeneration of

membrane.BenefitsFrom difficult to treat to easy to treatBirth of

CVD filter is a breakthrough, and this remarks the industry is

endowed with an economic and highly efficient solution for viscous

materials, and as for general materials, CVD's filtration

efficiency increases to a new level.Application industriesPromote

the development of industries more widelyOther than the application

in fields such as traditional hydrometallurgy, FGD gypsum

dehydration, CVD filter is able to promote the development of wider

fields such as pigment processing, concentration of battery

materials.Filtration Area m²Plate Size Plate Number/cycle Plate NumberVolume m3Size(L×W×H)mm1 1 m2/Cycle 1 12 0.2 1400×1400×1900 4 2 m2/Cycle 2 24 0.8 1700×2200×2000 6 3 36 1.1 2000×2200×2000 9 3 m2/Cycle 3 36 1.9 3100×2800×2600 12 4 48 2.6 3400×2800×2600 15 5 60 2.9 3700×2800×2600 21 7 84 3.9 4300×2850×2600 24 8 96 4.3 4600×2850×2600 30 10 120 5.2 5200×2850×2600 36 12 144 6.1 5800×2850×2600 45 15 180 7.4 6700×2850×2600 40 4 m2/Cycle 10 120 7.0 5200×3200×3000 48 12 144 8.2 5800×3200×3000 60 15 180 10.0 6900×3300×3000 80 20 240 14.5 8400×3300×3000 40 5 m2/Cycle 8 96 5.8 4900×3300×3100 45 9 108 6.0 5200×3300×3100 50 10 120 6.9 5500×3300×3100 55 11 132 7.5 5800×3300×3100 60 12 144 8.1 6100×3300×3100 100 20 240 12.7 8500×3300×3100 78 6 m2/Cycle 13 156 12.7 6400×3700×3300 96 16 192 15.1 7300×3700×3300 120 20 240 18.3 8500×3700×3300 96 12 m2/Cycle 8 120 25 6730×5900×4780 120 10 150 30 7530×5900×4780 144 12 180 35 8570×5900×4780 168 14 210 40 9370×5900×4780 192 16 240 45 1020×5900×4780 FILTANGOur

mission is to develop industrial filtration technology and promote

sustainabledevelopment of the worldOn June 24, 2019, a group of

engineers who wish to prove that new filtration technology is

better, faster and has more possibilities than traditional

filtration technology created Filtang. Filtang not only has the

capability in developing high-end filtration technology, but also

promotes the development of the overall industry by spreading the

new intelligent technology. Filtang believes that human's prospect

will be more wonderful if industrial filtration technology stays

away from the reliance on limited water resource and energy and

moves forward to zero emission earlier.Filtang carried out research

and development work on horizontal vacuum filter, rotary table

vacuum filter, dynamic filter and cartridge filter in models such

as D1, and thus opened a new page of filtration technology in

China. After 1980s, founder team of Filtang began research and

development of a series of new filtration equipment in Nuclear

Industry East China Machinery Plant, Kunshan Chemical Machinery

Plant, Shanghai Chemical Machinery Plant, and Shanghai Feilong

Filtration Machinery Co., Ltd. Therein, full automatic vertical

filter press' performance is extraordinary, filter cake moi

Related products about Filtang CVD Disc Vacuum Filter

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup