Product descriptionStructure of embedded filter cloth, filter cloth

by sealing ring when installation, embedded within the filter

plate, filter without leakage, bring the sealing rubber ring, good

sealing performanceThrough their own embedded card installed on the

filter plate, not only reduces the installation process, to

facilitate tear open outfit, and make the feeding port not easy

appear plugging material phenomenon, filtering speed, uniform

filter cake washing, filtering clear filtrate, high recovery rate

of solidsFilter plate filter cloth is independent on the two

pieces, can change according to the need to separate, decrease the

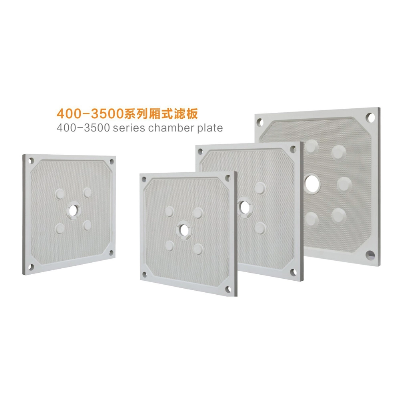

cost of filter cloth used.The company provides all series from

400*400 to 2000mmX2000mmProduct display Filter

cloth workshopOur Advantages1. More effectively reduce the moisture

content of the filter cake, reduce energy consumption, and improve

recovery rate, with fast filtration speed and uniform washing of

the filter cake. The water content of high-pressure filtration

materials is low. The filtrate is clear and the solid recovery rate

is high.2. High temperature, high pressure, anti-corrosion, and

excellent sealing performance. Embedded filter cloth with sealing

rubber ring, eliminating capillary leakage of filter cloth between

filter plates. The filter cloth has a long service life.3. Special

processing technology, specific imported materials, and long

service life of filter plates4. The filter plate is made of

high-strength and high molecular weight polypropylene material

extruded by a mold. Every product undergoes strict production

processes and standards. Specially designed to withstand

temperatures ranging from 0 to 95 degrees Celsius in different

usage scenarios, with a maximum filtration pressure of up to 2MPA5.

The precision filter plate surface processed according to the

German industrial standard DIN 7129, together with the filter

cloth, ensures good sealing of the filter plate components. The use

of CGR design ensures that there are no leaks. The surface

hydrophobic filter plate has a water absorption capacity of less

than 0.1%6. We can customize the best solution for you based on

your industry type, scale, usage, and precise data from various

aspects.7. Reasonable price and good cooperation experience with

major customers around the world8. Acceptable sample orders with

high cost-effectiveness9. Fast delivery time and attitude towards

solving problems

quicklySpecificationsFeedingModelPlateThickness(mm)Board

thickness(mm)Inlet diameter (mm)Inlet thickness(mm)Washing

holesize (mm) Maximum feed pressureStandard drivepipeFood

quality≤50≤75≤90≤110≤120ºCºCºCºCºCCenterXR40025506220200.60.40.2 PPX7 XR63030607020250.60.40.2 PPX7CenterXR80030609030500.60.40.2 PPX7 XR1000306010030500.60.40.2 PPX8CenterXR1250306012530650.60.40.2 PPX8 XR1500357015030800.60.40.2 PPX8Up

and

downXR18004085125 100 0.2 304X7 Product

catalog About usZhejiang Fujie

Environmental Protection Equipment Co., Ltd. was established in

June 2016 and is a wholly-owned subsidiary of Shanghai FujieThe

company has 60000KN, 80000KN, and 120000KN ultra large injection

and pressure equipment, with the largest tonnage of oil pressure

machines in the industry and multiple three axis machining centers

and several five axis machining centers, making it the first

enterprise in the industry to use five axis machining.The unique

raw materials and formulas for filter plate manufacturing ensure

various performance indicators and mechanical strength, and the

material is uniform and dense. The company has passed three

major management system certifications: ISO9001, ISO14000, and

OHSA45001. Largest tonnage of oil pressure machines in

the industry Five axis machiningcenter(first one to use in

the industry) /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Fully Enclosed Filter Cloth Embedded Filter Plate for Sludge Sewage Treatment/Diaphragm/Membrane/Filter Press Parts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup