PRODUCTS SPECIFICATION 254SMO Stainless Steel Pipe Tube UNS

S31254 Stainless Tube SCH40 SCH80ASME SA 213 ASTM A213 ASTM A269

S31254 254 SMo EN 10216-5 1.4547 Alloy 6Mo X1CrNiMoCuN20-18-7

Tubing is an superaustenitic stainless steel designed for maximum

resistance to pitting and crevice corrosion. With high levels of

chromium, molybdenum, and nitrogen, 254SMo is especially suited for

high chloride environments such as brackish water seawater pulp

mill bleach plants and other high chloride process streams. 254SMo

Pipe offer chloride resistance superior to that of Alloy 904L,

Alloy 20, Alloy 825 and Alloy G. Copper improved corrosion

resistance in some of the acid . In addition, due to its high

content of nickel,chromium and molybdenum, so that 254SMo S31254

Tubing has a good stress corrosion cracking performance. 254

SMo S31254 Tubing is compatible with the common austenitic

stainless steels. In new construction, 254SMo has been found in

many cases to be a technically adequate and much less costly

substitute for nickel based alloys and titanium. 254SMo is

substantially stronger than the common austenitic grade, also

characterized by high ductility and impact strength. 254SMo is

readily fabricated and welded.254 SMo S31254 Tubing is

face-centered cubic lattice structure. In order to obtain

austenitic structure, 254 SMo S31254 Tubing general annealing in

the 1150-1200°C. In some cases, the material may have traces of

metal middle phase (χ phase and α-phase). However,their impact

strength and corrosion resistance are not adversely affected in

normal circumstances. When placed in the range of 600-1000°C, they

may phase in the grain boundary precipitation. Products

Specification of 254SMO Stainless Steel Pipe Products

Name254SMO Stainless Steel pIpeDiameterDN6 - DN500Wall

ThicknessSCH10S - XXS or unstandard size as requestLength6m or

cutting any length as requestStandardASTM JIS EN

DIN Technique Hot Rolled / cold drawnTypeSeamless Pipe /

Welded PipeOther Grade201 304 304L 309S 310S 316L 316Ti 316LMod

317L 321 347 410 904L 254SMO 253MA 2205 2507 654SMO 926 400 c276

c22 C4 600 625 800 825.etcMOQ500 kgsLoading PortShanghai

PortPackingwooden box or ppbagMATERIAL DESCRIPTION254SMO Pipe

S31254 Chemical compositionASME SA213

S31254 Alloy%NiCrMoCuNCMnSiPSS31254Min.17.519.56.00.500.18-----S31254Max.18.520.56.51.000.220.0201.000.800.030.010 ASTM

A269

S31254 Alloy%NiCrMoCuNCMnSiPSS31254Min.17.519.56.00.500.18-----S31254Max.18.520.56.51.000.250.0201.000.800.0300.015 PRODUCTS

APPLICATION254 SMO S31254 Tubing S31254 Tubing ApplicationThe most

corrosion resistant stainless steel contains 6% to 7.3% Mo. Such as

254SMo alloy steel are used as power plant condensers, subsea

pipelines, and key components of nuclear power plants, such as

industrial water pipelines.1. Petroleum, petrochemical equipment,

petro-chemical equipment, such as the bellows.2. Pulp and paper

bleaching equipment, such as pulp cooking, bleaching, washing

filters used in the barrel and cylinder pressure rollers, and so

on.3. Power plant flue gas desulphurization equipment, the use of

the main parts: the absorption tower, flue and stopping plate,

internal part,spray system.4. At sea or sea water processing

system, such as power plants using sea water to cool the

thin-walled Condenser, desalination of sea water processing

equipment,can be applied even though the water may not flow in the

device.5. Desalination industries, such as salt or desalination

equipment.6. Heat exchanger, in particular in the working

environment of chloride ion.7. Hydraulic Tubing and instrumention

tubing8. Tanks and pipelines for chemicals with high halide

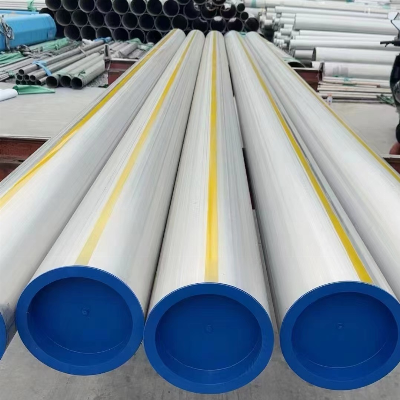

contentsPRODUCTS PICTURES /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 254smo Stainless Steel Pipe Tube Uns S31254 Stainless Tube Sch40 Sch80

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup