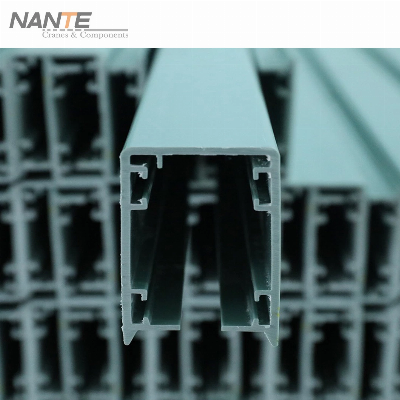

Enclosed Multiple Conductor Rail HFP52 Mobile Power SupplyProduct

DescriptionSpecifications of HFP52 Multi-pole Conductor

Rail 1. Application: crane, power plants, electrical

production 2.CE, CCC, ISO9001 ApplicationThe ranges

of applications of HFP Power Rail Enclosed Conductor SystemOverhead

and elongated tracks for cranes. Electric hoists, electric

tools, stacking systems.Electric toolsOther applications for

supplying power to moving power load. Design

features Compact arrangement, corrosion resistance and simple

assembly are its essential features. HousingColor green, PVC

housing for 4 conductors. Standard section 4 m.Other sections are

available.The ground conductor is identified by international color

code.Phase reversing prevented by design of the collector and

housing. Current collectorsThe current collectors are made of

re-inforced polyester fiberglass,for high strength and light

weight.Spring loaded carbon brushes maintain uniform

contact.Connecting cables and hinged or flexible towing arms

included.Double Current collectors for transfer applications and

higher amperage. CouplingsThrough PVC joint caps.Feed

SetsLine feeds or end feeds.End capsThe open ends of the powerail

are closed by end caps for HFP.HangersStandard brackets for

powerail attachment to crane girders are available.Powerail with

sliding and fixpoint hangers.Standard distance between suspension

points for indoor and outdoor

installations:1200mm. HangersStandard brackets for powerail

attachment to crane girders are available.Powerail with sliding and

fixpoint hangers.Standard distance between suspension points for

indoor and outdoor installations:1200mm. Expansion

during temperature fluctuation The Expansion sections are

required to compensate the different expansions between copper

conductors and steel-or concrete structures,in varying temperatures

without interrupting electrial power. Anti-condensation

sectionsThese sections are used for transfer of the Powerail to

outdoor areas to avoid condensation. SectionalizingAvailable

as air gap version (5mm),where the collector carbon bridges the

gap,e.g.for mains. Technical Parameters HFP Series

Multiple-Poles Conductor Rail SystemMax. voltage600vBending

strength75N/mm²±10%Dielectric strength30-40kv/mmTensile

strength40N/mm²±10%Special resistance5×1015 Ohm×cmLeakage

resistanceCTI600-2,7Surface resistance1013 Ohm×cmDesign and

Manufacturing StandardGB7251.2-2006Distance between each suspension

bracket (m)1.2Rail length per piece (m)4Flame retardantClass B1-no

flaming particles, self-extinguishingPermissible Ambient

temperatureStandard insulation -30°C- +70°C|High temperature

insulation -20°C- +115°C|Low temperature insulation -40°C-

+80°C ModelPole No.Cross sectionMax.

currentLeakage-distanceMax.

voltageResistanceWeightHFP52-4-10/5041050556001.6562.05HFP52-5

-10/5051050156001.6562.14HFP52-6-10/5061050156001.6562.23HFP52-7-10/5071050156001.6562.32HFP52-4-15/8041580556001.1372.32HFP52-5-15/8051580156001.1372.44HFP52-6-15/8061580156001.1372.58HFP52-7-15/8071580156001.1372.71HFP52-4-20/100420100556001.0112.47HFP52-5-20/100520100156001.0112.65HFP52-6-20/100620100156001.0112.83HFP52-7-20/100720100156001.0112.99HFP52-4-25/120425120556000.7132.63HFP52-5-25/120525120156000.7132.83HFP52-6-25/120625120156000.7133.02HFP52-7-25/120725120156000.7133.27HFP52-4-35/140435140556000.5222.97HFP52-5-35/140535140156000.5223.25HFP52-6-35/140635140156000.5223.58HFP52-7-35/140735140156000.5223.87

Company Profile FAQ Q1: Are you

Manufacturer or Trading Company?A1:We are an integrated industrial

and trade enterprises. We have our own R&D team, factory and

marketing department,Q2: Which standard of your crane and crane

components apply to?A2: Our Crane can design and manufacture base

on FEM, CMAA, ISO EN, GB standard.Q3: How do you ensure your

product quality?A3: All our processes strictly adhere to ISO-9001

procedures, which include Material Traceability, ISO WPQR and

welder certificate, Measuring Device Calibration, NDT for the

welding, and full assembling and load testing before delivery.Q4:

How can I make payment?A4: We accept T/T bank transfer, L/C,

Paypal.Q5: How can I assembly the cranes in my factory?A5: We

suggest you to recruit a crane service team in local to install the

crane base on our Installation Guideline and User manual. If

cannot, we can send engineer to your factory to guide you do the

installation with extra charge, and the transportation,

accommodation, translator shall be covered by your side also.Q6:

What is the warranty period, and how can I claim warranty If my

crane have any issue?A6: Our warranty period is 12 months after

cargo leave China port. If the crane have any issue, our

after-sales team and engineer will help you solve the issue by

email or Video conference. If the defect is caused by quality

issue, we will ship the spare parts to you by air to help you fixed

it as soon as possible.Q7: Do you accept OEM business?A7: Sure, we

do many OEM productions for some famous

Related products about Enclosed Multiple Conductor Rail Hfp52 Mobile Power Supply

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup