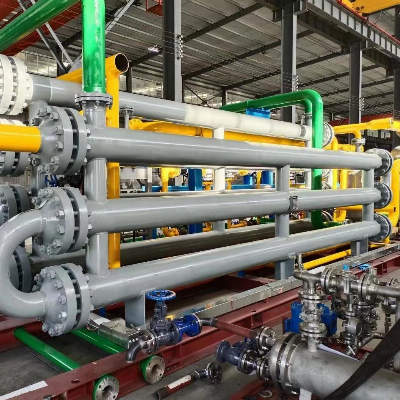

About Us Greenfir offers a complete line of reciprocating

compressors, many built to strict API 618 and ISO 13631 standards,

and all backed by a global service network. These comprehensive

capabilities allow us to manage a wide range of energy conversion

projects for our clients. We can engineer, manufacture, procure,

test, deliver, install, operate, and maintain your entire

compressor system. Our extensive application experience with all

major drive systems, including motors, engines, and turbines-allows

us to precisely match the drive train to the compressor for maximum

efficiency and reliability. We also provide all compressor

accessories, piping, and packaging necessary to meet your total

process and installation requirements. Our packaged units are ready

for modular installation, with all compressor drive, lubrication,

coolant, pulsation dampening, and control systems in place. This

integrated approach simplifies ordering, delivery, and

installation; reduces your coordination time and expense; lowers

your engineering and construction costs; and provides singlesource

accountability. Product Description The compressor adopts

symmetrical and balanced structure, with two throws, two cylinders

and two-stage compression. The cylinders are respectively located

on each side of the frame. The gas inlet and outlet ports of the

cylinders are arranged according to the upper inlet and lower

outlet, with double function. The cylinder is equipped with an

independent jacket, which is cooled by circulating water. The

compressor will be located indoor with one layer arrangement. The

distance piece adopts D-type long and short double compartments in

article 6.12.1.5 of API 618, and the compartment is equipped with

integral metal cover plate with gasket. The average piston speed is

3.564 m/s. The crankshaft speed is 594 r/min. The actual gas outlet

temperature (@cylinder flanges) is ≤ 100 °C. The cylinder and

packing case are with oil-free lubrication design and less oil

lubrication operation. The compressor capacity control adopts the

combined control of bypass and pneumatic unloading. Use the

pressing-off suction valve for unloading. All unloading valves are

air unloading, the load selection switch is located on the local

instrument panel of the compressor unit, with 0, 50, 100% third

gears, and the unloader is finger type. At the same time, "Stage-1

outlet reflux Stage-1 inlet" manual adjustment loops and "Stage-2

outlet reflux Stage-1 inlet"(Automatic regulating valve group) are

equipped for capacity control and starting the compressor unit

without load. Utilities

ConsumptionsItemApplicationVolts.PowerWorking MethodElectricityMian

motor6 kV710 kWContinuousAux. oil pump380 V3 kWIntermittentElectric

heater of lube oil tank220 V3 kWIntermittentMain motor electric

heater220 V1 kWIntermittentCirculating waterStuffing box2

m3/h/ContinuousCylinder10 m3/h/ContinuousLube oil cooler5

m3/h/ContinuousProcess gas cooler//ContinuousAirInstrument air10

Nm3/h/IntermittentNitrogenPacking2 Nm3/h ContinuousPurchasing

GuideBefore sending us your RFQ, plz consider the following items

are included in your MR or Duty Specification.1) Feed gas

composition (inclduing, flowrate, suction pressure, suction

temperature and gas components)2) Site consitions (including, ASL,

ambinet trmperature [max. & min], relative humidity, circulating

water avaliable or not, power supply or not, rainfall, prevailing

wind, seismic category, etc.)3) Product gas specification/

requirements (including, discharge pressure, discharge temperature,

etc.)4) Scope of work and supply.5) Applicable codes, standards and

regulation (API 618, ISO 13631, GB?)6) Others (skid-mounted,

enclosure, variable frequency driver, soft starter?)7) Master

documents list (MDL), such as, BFD, PDF, P&ID,GAD, etc.After

Sales Service1. Site services: supervision of erection,

commissioning & start-up, traning of the operators.2. Two years'

spare parts within 20 years are avaliable.3. Engineering (basic &

detail engineering) for the whole station./* March 10, 2023

17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Water Cooled Balanced Opposed Process Reciprocating Ethylene Compressor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup