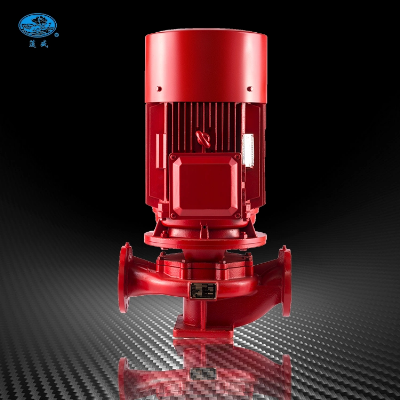

Product Description Products Name: UL listed fire pump with

Vertical Single-Stage Overview: XBD vertical single-stage fire pump

set is based on our IS type pump, combined with the characteristics

of foreign pipeline pump, optimization design and manufacture of a

new generation of products by itself. Use of fire hydrants in the

water, feeding sprinkler system water supply in other occasions

cleaning liquid. Conditions of use:1. XBD vertical single-stage

fire pump set is used for transporting ambient water. 2. The water

does not contain corrosive substances and solid particles. 3

Minimum working pressure 0.3Mpa, the maximum working pressure of

1.6 Mpa. Characteristics of XBD vertical single-stage fire pump

products 4, the pump is a vertical structure, import and export of

the same caliber, and are in the same center line, as the valve can

be installed in the pipeline, compact appearance, small occupation

area, low construction inputs, such as protective cover can be

placed outdoors 5, the impeller mounted directly on the motor

lengthened shaft, short axial dimensions, compact structure, pump

and motor bearings reasonable configuration, can effectively

balance the pump running the radial and axial load, so as to ensure

the operating balance vibration noise of the pump is very low. 6,

seal mechanical seal mechanical seal or a combination, the use of

imported titanium alloy seal ring, medium and high temperature

mechanical seal with cemented carbide materials, wear-resistant,

can effectively increase the service life of mechanical seal. 4,

convenient installation and maintenance, no need to open the

pipeline system, remove the pump as long as the union nut can block

out all the rotor parts. 5, can be used according to the

requirements that need to flow and head of the pump series,

parallel operation. 6, according to the requirements of piping

layout using the vertical and horizontal pump installation.

Performance requirements of fire pump is:1. Maximum flow fire pump

shall be 150% of the value of the design, the head is not less than

the selected operating point of 65% lift, lift off the pump when

not greater than the selected operating point of 140% lift, pump

flow 1 2LS, head 1.1 - 1.2 times the fire pump lift. 2. At the same

time in the fire pump outlet pipe should be located on measurement

flowmeter, flow meter should be able to test 175% of the pump flow

rate selected, fire pump pressure gauge set should be greater than

89mm in diameter at the outlet pipe. fault

phenomenonfailure causeelimination methods 1.No

power supply or one or two phase power supply is needed Check

all phases of power supply and restore power

supply 2.Poor contact of ac contactor and burning

of coil Repair or replace

contactors can not start3.The power switch is

not closed, malfunction or damaged Close the switch and

replace it if the power indicator does not turn on 4.Thermal

relay trip or damage Check whether the motor is blocked,

find out the reason and eliminate it.Manual reset is replaced if it

cannot be started Water level is too low Put water in the

sink The motor burned Repair or replace the

motor 1.Line is loose Check wiring and

tighten connectors 2.Frequency converter

malfunctionCheck the fault content, check the cause according to

the frequency converter manual, and restart after reset.Or

disconnect the inverter power supply for a few seconds, the

inverter fault reset before starting.The manual is normal3The

frequency converter is damagedRepair or replaceAutomatic

transmission failure4.Pressure switch damageRepair or

replace 5The pressure transmitter is damagedRepair or

replace 6.Switch failureRepair or replacePump non - suction

pressure gauge pointer to beat violentlyInsufficient water supply

for perfusion, air leakage at the connection between pipeline and

instrumentCheck pipeline and bottom valve, refill water diversion.

Tighten air leakage The pump consumes too much

power Too much flow, impeller

wear Check whether the pump shaft is bent, replace the

impeller, close the outlet valve to reduce the flow♦ ESTABLISHED IN

THE SIXTIES♦ ONE OF THE FIRST THROUGH THE ISO9001:2008 DOMESTIC,

INTERNATIONAL QUALITY SYSTEM CERTIFICATION ♦ SILVER MEDAL WAS

AWARDED AT THE NATIONAL CONFERENCE ON THE APPLICATION OF SPARK CUP

TECHNOLOGY ♦ WIN THE NATIONAL AWARD FOR EXCELLENCE IN CIVILIZATION

COMPETITION ♦ GET THE LC OF THE CHINESE GOVERNMENT /* March

10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Fire Pump with Vertical Single-Stage

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup