Product detailsSpecifications. Normal temperature

type:-15C~+70C Hot water type:+70C~+120CAmbient temperature

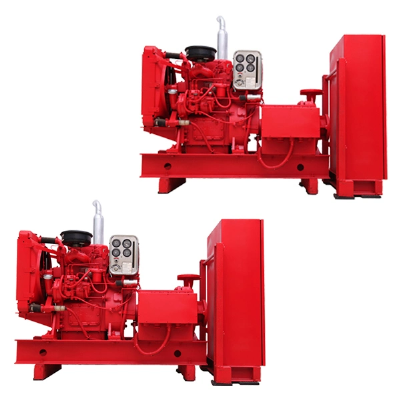

:up to +40C1. Application Conditions:XBC Diesel Fire Fighting Pump

Group is aplicable for conveying water at room temperature or the

liquid resembing water, or for water of fire fighting or

others. 2. Performance Parameters:Rated Flow Q=10~250 L/SRated

pressure Mpa=0.3~1.05MpaRev n=1500, 2000, 2200, 2400 r/minHP

P=17.7~243 HPInlet diameter DNa=125~450 mmOutlet diameer DNa=80~350

mmAllowable working pressure≤ 25 bar 3. Advantages:Starting

automatically when there is no power supplyEffectiveStable and

reliable runningEasy maintainingLong service life 4.

Applications:water supply to fire spraying system fault

phenomenonfailure causeelimination methods 1.No

power supply or one or two phase power supply is needed Check

all phases of power supply and restore power

supply 2.Poor contact of ac contactor and burning

of coil Repair or replace

contactors can not start3.The power switch is

not closed, malfunction or damaged Close the switch and

replace it if the power indicator does not turn on 4.Thermal

relay trip or damage Check whether the motor is blocked,

find out the reason and eliminate it.Manual reset is replaced if it

cannot be started Water level is too low Put water in the

sink The motor burned Repair or replace the

motor 1.Line is loose Check wiring and

tighten connectors 2.Frequency converter

malfunctionCheck the fault content, check the cause according to

the frequency converter manual, and restart after reset.Or

disconnect the inverter power supply for a few seconds, the

inverter fault reset before starting.The manual is normal3The

frequency converter is damagedRepair or replaceAutomatic

transmission failure4.Pressure switch damageRepair or

replace 5The pressure transmitter is damagedRepair or

replace 6.Switch failureRepair or replacePump non - suction

pressure gauge pointer to beat violently Insufficient water

supply for perfusion, air leakage at the connection between

pipeline and instrumentCheck pipeline and bottom valve, refill

water diversion. Tighten air leakage The pump consumes too

much power Too much flow, impeller

wear Check whether the pump shaft is bent, replace the

impeller, close the outlet valve to reduce the flowRelated

productsCompany Information ♦ ESTABLISHED IN THE SIXTIES♦ ONE

OF THE FIRST THROUGH THE ISO9001:2008 DOMESTIC,INTERNATIONAL

QUALITY SYSTEM CERTIFICATION♦ SILVER MEDAL WAS AWARDED AT THE

NATIONAL CONFERENCE ON THEAPPLICATION OF SPARK CUP TECHNOLOGY♦ WIN

THE NATIONAL AWARD FOR EXCELLENCE IN CIVILIZATION

COMPETITION ♦ GET THE LC OF THE CHINESE

GOVERNMENT CertificationTransportationFAQ /* March 10,

2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Diesel Engine Driven Centrifugal Fire Pump

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup