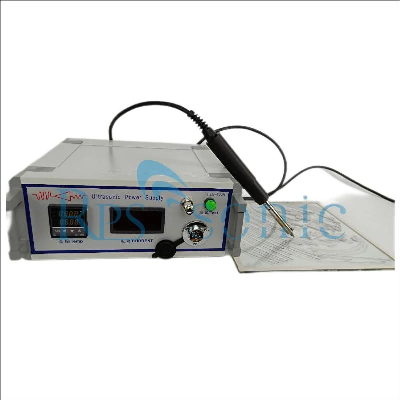

60Khz ultrasonic soldering iron equipmentModel No.HC-SI60Ultrasonic

Frequency60KhzMaximum Output100 WattTemperature Range150 ~ 400

°CPower Supply220V / 50-60 HzUltrasonic GeneratorSize250(W) x

310(L) x 135(H) mmWeight5 KgFeatureUltrasonic Amplitude

AdjustableIron Handle Length & Diameter190mm / Ø20Avail Soldering

MatrialITO Glass, AL, Mo, Cu etc.,Ultrasonic soldering is a

flux-free soldering method that is considered more environmentally

friendly than conventional soldering methods. Use vibration and

cavitation to remove surface oxide layers from welding surfaces,

not chemicals.Ultrasonic soldering technology is different from

ultrasonic plastic welding, which uses vibration to generate heat

to melt the connected parts. The principle of use of ultrasonic

soldering is basically the same as the process of ultrasonic

cleaning. The vibration energy causes cavitation in the water bath

or cleaning solvent. For the part immersed in the liquid medium,

the surface is cleaned by the strong erosion action of cavitation

bubbles.During ultrasonic soldering, heat from a separate energy

source melts the solder prior to applying vibrational energy. The

molten solder is then used as an acoustic transmission medium for

ultrasonic vibrations. When high frequency vibrational energy is

applied to molten solder, controlled acoustic cavitation is induced

at the tip of the soldering tool in order to destroy and disperse

surface oxides. Cavitation microbubbles burst, cleaning all

surfaces, allowing liquid solder to wet and bond pure metal.The

vibration also ensures that the solder joints are free of voids,

and the vibration energy forces the liquid solder to penetrate into

the crevices and pores of the substrate. It helps seal the part and

increases the surface area where the solder can bond. Ultrasonic

vibration can also squeeze air bubbles out of the liquid solder, so

this method makes the solder joint suitable for high vacuum

applications where sealing is required.Ultrasonic soldering allows

dissimilar materials to be joined and can be used for materials

that are difficult to solder with conventional methods. By

eliminating the need for flux, users can save time and cost in

cleaning flux residues, while reducing corrosion and improving the

durability of soldered joints.The ultrasonic soldering method can

be conveniently used for manual soldering with the help of

hand-held ultrasonic electric soldering iron equipment, and can

also be grafted to ultrasonic welding machines and assembly

lines.Glass, ceramic, stainless steel, aluminum weldingAfter years

of extensive research into glass-to-metal bonding, Japanese

engineers developed a special solder alloy called CERASOLZER

(solder wire). This reactive solder alloy is specially formulated

to cooperate with ultrasonic welding methods, and has a very unique

bonding ability, which can replace the commonly used silver baking,

indium brazing, molybdenum manganese and resin bonding methods.

CERASOLZER Bonding (Glass Substrate) In addition to direct

metal-to-metal bonding, Cerasolzer can also form strong chemical

bonds with soldered substrates. The alloy consists of the same main

components as standard solder alloys (lead/tin), but in addition it

also contains small amounts of elements such as zinc, titanium,

silicon, aluminum, beryllium, rare earths, etc. Strong chemical

affinity.During the welding process, these additional elements

combine with the surrounding oxygen to form an oxide that

chemically bonds to a variety of materials, including glass,

ceramics, aluminum, stainless steel, conductive oxides and many

formerly Other substrates considered non-solderable. The resulting

oxides bond with the solder substrate, forming extremely strong

chemical bonds (RO) at the interface.Therefore, if the oxygen is

effectively eliminated by replacing the air surrounding the bonding

device with an inert gas such as nitrogen, the Cerasolzer's

adhesion will be lost. The results show that the suitable critical

oxygen concentration for bonding is about 2%. The melting

temperature of Cerasolzer alloy is between 155 and 297°C, and the

welding method is flux-free due to ultrasonic vibration. In fact,

if our ultrasonic welding method uses flux, it will destroy the

oxygen bond and destroy the whole welding process, so it should not

be used.Glass jewelry manufacturingOptical glasses

coating/metallizationMaking electrodes on glass and ceramic

platesHeating contact welding in car rear windowWelding

superconductors, components, ceramic accessoriesGlass tube vacuum

sealing, hardware accessories bondingSealing of optical glass

fibers (ferrule bonding)Electrode bonding to front/back contacts of

solar cells (crystalline, thin film)Lead (dot) bonding on metallic

glass, liquid crystal glass, crystal oscillator, hybrid integrated

circuit /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 60kHz Ultrasonic Soldering Iron Equipment

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup