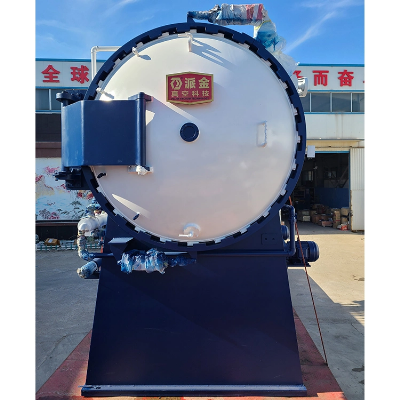

Product DescriptionVacuum Oil Quenching furnaceVacuum

oil quenching is to heat the workpiece in the vacuum

heating chamber and move it to the quenching oil tank. The

quenching medium is oil. The quenching oil in the oil tank is

stirred violently to cool the workpiece quickly.This model has

the advantages that bright workpieces can be obtained through

vacuum oil quenching, with good microstructure and

performance, no oxidation and decarburization on the surface. The

cooling rate of oil quenching is faster than that of gas

quenching.Vacuum oil is mainly used for quenching in vacuum oil

medium of alloy structural steel, bearing steel, spring steel, die

steel, high-speed steel and other materials. APPLICATIONS

Paijin Vacuum Oil Quenching Furnace is mainlly used for bright

quenching,hardening and tempering of alloy steel,alloy structure

steel,die steel ,spring steel, bearing ,steel, stainless steel,

precision alloy steel, and sintering, bright annealing and vacuum

brazing of various magnetic materials. CharacteristicsPaijin

Vacuum oil quenching furnace is one of our star products, in our

design, We have fully considered the characteristics of vacuum

oiling process, strengthened the control of quenching oil

temperature and frequency conversion control of mixing device, and

can achieve perfect oiling conditions. At the same time, we have

strengthened the sealing of the heating furnace and the insulation

design of heating elements, reduced the pollution of heating

elements and furnace caused by vacuum oil pollution, and prolonged

the service life of the vacuum furnace.1. High temperature

uniformity: Its heating elements are evenly set all around the

heating chamber makes its temperature difference is less than 5

degrees.2.Capable of continuous production: it has separate heating

room and quenching room.3.Better cooling uniformity, less work

piece deformation: Oil stirrer with variable frequency speed

controller and flow guide mechanism.4. It's capable of : constant

temperature quenching, isothermal quenching, convection heating,

vacuum partial pressure.5. Good mechanical action stability, big

load weight, and the material vehicle is automatically operated.6.

With whole AI control system and an extra manual operating

system.7. Smart and easy for process programming, stable and

reliable mechanical action , automatically, semi automatically or

manually alarming and displaying the faults.Standards:DIN 17052 - 1

"Heat treatment furnaces - Part 1: Requirements for temperature

uniformity"EN 60519 -2 "Safety in electroheat installations - Part

2: Particular requirements for resistance heating

equipment"AMD2750D "AEROSPACE MATERIAL SPECIFICATION"NFPA86D

"Standard for Ovens and Furnaces"GB/T 16876 "Vacuum test

standard for double wall equipment"GB/T 10066.1 " Test methods

for electroheating and electromagnetic processing

installations"GB/T 9452 "Testing Method For Working Zone

Of Heat Treatment Furnace"Detailed PhotosProduct ParametersStandard

model specification and

parametersModelPJ-OQ557PJ-OQ669PJ-OQ7711PJ-OQ8812PJ-OQ9916Effective

Hot Zone LWH

(mm)500*500*700600*600*900700*700*1100800*800*1200900*900*1600Load

Weight(kg)30050080012002000Maximum Temperature(ºC)1350Temperature

control accuracy(ºC)±1Furnace temperature uniformity(ºC)±5Maximum

Vacuum Degree(Pa)4.0 * E -1Pressure raise rate (Pa/H)≤

0.5Transfer time (s)1010152030Gas cooling pressure(Bar)2Furnace

structureHorizontal, Double chamberFurnace door opening methodHinge

typeDrive method of Heat insulation doorMechanical typeHeating

elementsGraphit heating elementsHeating chamberComposition

structure of Graphit hard felt and soft feltAir cooling

typeInternal heat exchangerPLC & Electric elementsSiemensOil flow

typePaddle mix typeTemperature controllerEUROTHERMVacuum

pumpMechanical pump and roots pumpCustomized optional rangesMaximum

temperature600-2800 ºCMaximum temperature degree6.7 * E -3

PaFurnace structureHorizontal,Vertical, double chambers or multi

chambersDoor opening methodHinge type, Lifting type,Flat

typeHeating elementsGraphit heating elements, Mo heating

elements;Ni-CrAlloy Strip heat elementHeating chamberComposed

Graphit felt; Alloy metal reflecting screen; Stainless

steel reflecting screenAir cooling typeInternal heat exchanger;Out

cycle heat exchangerOil flow typePaddle mix type;Nozzle inject

typeVacuum pumpsMechanical pump and roots pump; Mechanical, roots

and diffusion pumpsPLC & Electric

elementsSiemens;Omron;Mitsubishi;SiemensTemperature

controllerEUROTHERM;SHIMADEN Relative

information Hi,my friend, thanks for checking Paijin

Vacuum furnaces. I will show you why our products are your

best choose.Technical advantages:Energy saving: By using our

self-owned registered patented technology of energy saving, our

furnaces saves 20%-40% energy than other brands in heating. Reduces

muh cost.High Intelligent Control system:All our furnaces are

equiped with our high intelligent control system, it can realize

one button operation by the recorded data an

Related products about Paijin Brand Vacuum Oil Quenching Furnace

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup