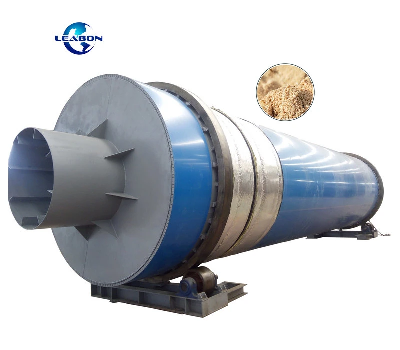

Brief Introduction of Wood Dryer:It is suitable for

dryingsensitive material like sawdust, rice

hull, milledwheat straw, milled cotton / corn

stalksand so on.It is made up of heat stove, tube, impulse jar,

function tube, fan, and cycloneseparator.It can reduce

moisture from 40-45% to 8-12%.Fuel for the furnace:

wood waste, coal. Waste oil and so on.(Note: If the moisture

of raw materials is more than 45%, the furnace required the bigger,

please inform us when ordering.) The Description of Wood

Dryer:Pipe drier is very important for further

briquetting/Pelletizing process. To get the superior quality of

biomass with high density, it is necessary to control the moisture

of material at 8-12% exactly. The selection of drying plant models

depends on the original moisture content of raw materials.

The Main Specification of Wood

Dryer:ItemLB-260ALB-300ALB-350ADrying speed

(kgs/h)200-250300-400600-700Main power (Kw)47.5-1111Max diameter

(mm)7809001050Min diameter (mm)260300350Furnace

(mm)1600*900*1150mm;1230kgs2000*1000*1300mm;1450kgs2100*1020*1330mm;1750kgsRoute

(m)182635Dimension (m)9*2.5*3.116*2.5*3.222*3*3.3Total

weight1760kgs2660kgs3460kgsHot air temperature150-200ºCMoisture

content before drying40%-50%Moisture content after

drying8%-12%Airflow velocity8m/sThe Advantage of Wood

Dryer:1. Strong drying strength: high aire flow speed,

the material can disperse well. 2. Air drying time is

short: drying time is about 0.5 to 5 seconds, the heat

sensitivity or low melting point material will not cause

overheating or decomposition to affect its quality. 3.

Airflow dryer has high thermal efficiency: airflow drying material

and air flow cocurrent operation, the material and air

temperature can reach a reasonable state, the drying time is short,

which can use a higher drying temperature. 4. Wide range

applications, high yield, large precipitation; simple structure,

small station area, low investment and maintenance costs. 5.

Air air Source:furnace, gas stove, coal stove, steam heat

exchanger. The Principle of Wood DryerIn the dryer, high-speed

hot air stream sustain raw material in the suspending state, then

the material is dried. Since air stream speed is very high, and

materials suspending in air stream, the heat transfer surface

between air and raw material is large, so the heat transfer rate is

high.It can reduce moisture

from 40-45% to 8-12%.Fuel for the furnace: wood

waste, coal. Waste oil and so on.The Spare Parts of Wood

DryerThe whole system consists of fan blower, motor engine, fuel

boiler, steel pipe, cyclone and air lock.Wood Dryer for wood pellet

line:Detail Quotation Solutions for you, we need to know

Informations as Follows: (1). What is Your Raw Materials or

Tell Us Your Materials Moisture Content? -----Different moisture

content of your raw materials, with different size of Rotary Drum

Sawdust Dryer for you. We need to know what is your raw

materials, moisture content of it? and final capacity demand?

(2).What is Your Fuel for Rotary Drying Machine? -----There are

kinds of biomass could be Fuel for Rotary Drying Machine, if you

have special demands please let us know. Like: Automatic Feeding

Fuel for Rotary Drying Machine or not? (3).Rotary Drying

Machine Adjustable Items: -----Feeding Heat Temperature Could

Adjustable, Rotation Speed Adjustable. All according to your raw

materials information, moisture content and capacity demands.

Related Products of Woodworking Machinery1. Hot Sale Wood Pellet

MillThis wood pellet machine is suitable for making biomass

particles such as sawdust, rice husk, paddy straw, sunflower stalk,

hulls, forestry wastes pellet, etc. 2. Production Flow Chart of

Complete 1T Biomass Wood Pelleting Plant ManufacturersWood Cutting

--- Sawdust Grinding ---- Drying ---- Pellet Making --- Cooling &

Screening ---- Packing IntroductionComplete 1T Biomass Wood

Pelleting Plant Manufacturers is the process of making waste

materials into solid fuel. The biomass pellet mainly used for

fuel.Suitable materialAgricultural waste, and forest or wood

residues from furnatures, such as sawdust, waste pallets, rice

husks, corn cobs, maize stalks, peanut shells, wood logs, and

etc.Size3-5mm, 10-15% moisturePellet size6-12mmCompany

Introduction:We Zhengzhou LEABON are specialized in produing the

wood pellet machine, feed pellet machine and the pellet product

line-------Wood debarker, wood chipper, wood crusher, cooler,

dryer, pack machine, baler etc. And also the filter press, wood

briquette machine. We can offer you the professional support and

advice on the using of the machine. With the high quality and also

the competitive price, our company have established many oversea

clients. You are welcomed to vist our company and know more about

the products. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Cylinder High Heat Temperature Rotary Drum Sawdust Dryer

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup