Company Profile The origin of CPM can be traced back to

California's Napa Valley, where, in 1883, the Toulouse & Delorieux

Co. Manufactured presses, crushers and stemmers for winemakers. In

1931, the company created the first pellet mill, the 30 HP Flat Bed

with stationary flat die, and we became California Pellet Mill

(CPM).In the years that followed, we created more pellet mill

models with additional features. In the 1980s, we greatly expanded

our product offerings through the creation of Roskamp Champion with

the acquisition of the Roskamp Roller Mill Company and Champion

Hammermills.Wolverine Proctor, part of the CPM Group in the United

States, founded in 1812, the company has a history of more than 200

years, starting from the production of textile machinery, after

more than two centuries of industry accumulation, now has been the

leader in the field of drying.Our dryers are sold to more than 100

countries around the world, and more than 10, 000 drying equipment

are in operation around the world, and continue to serve food,

chemical, textile chemical fiber,tobacco and other fields.We have

global team and can provide excellent drying solutions and services

for our customers.Wolverine Proctor products first entered China in

1912 and have accompanied the development and growth of various

industries in China for more than 100 years.Wolverine Proctor's

headquarters and production center are located in Lexington, North

Carolina, USA, as well as the North American Business and

Experiment Center in Horsham, Pennsylvania, USA, the European

Business and Experiment Center in Glasgow, Scotland, and the Asia

Pacific Business and Experiment Center in Wuxi, China.Wolverine

Proctor has the customized design technology reserves accumulated

by the century, extremely rich industry technology accumulation,

its huge application and design and service team with the common

development of food, chemical, textile chemical fiber and tobacco

fields in different regions of the world, and provides customized

large-scale drying, baking and cooling equipment solutions for

global customers.Our Advantages CHEMICALS Whatever the

chemical substance or form, we can help.When it comes to processing

heavy chemicals, pharmaceuticals, synthetic fibre, rubber,

plastics, minerals, mining, biomass, or any number of other

chemical substances, CPM Wolverine Proctor understands that

efficiency is key. With over 100 years of experience in the

chemical processing industry, we understand that

precision-engineered process equipment is vital to profitable

chemical processing operations.From raw material preparation for

process improvement to agglomeration or size reduction for

shipping, we combine our extensive chemical process experience and

engineering know-how with your unique processing needs to bring you

exacting quality equipment that just keeps running. Click the image

below to learn more about your chemical process application.

For rubber compounding processing that is

flexible and responsive.Your rubber compounding processing requires

flexibility, responsiveness, and adaptation. That's why CPM

Wolverine Proctor's processing equipment is built with your unique

configuration in mind. For consistently reliable performance and

optimal process efficiency, our flexible and world-class process

technology offers you a wide range of application solutions that

drive productivity and performance.CATEGORY

PRODUCTSBauxiteCellulose acetate flakesEPDMNBRNdBRRoofing

granulesRubber accelerator pelletsSBSSulphur pelletsProcessing

chemicals just the way you need.Whether you need to dehydrate, heat

set, sinter, harden, sulphurize, temper, chemically modify, gel,

cure, anneal, braze, cool, calcine, react, expand, or sterilize

chemical substances, we have the right solution that fits directly

into your chemical process operation. The experts at CPM Wolverine

Proctor can help you find the best solution. If it's optimizing the

physical characteristics of finished chemical-based products like

size, density, texture, or general appearance, our world-class

equipment will keep you running.CATEGORY PRODUCTSAir bag pellets

(sodium azide tablets)BauxiteCatalyst pelletsCellulose acetate

flakesClay pelletsMolecular sievePigments/iron oxide

(extruded)Roofing granulesRubber accelerator pelletsSaltSulphur

pelletsSuper absorbent gelTitanium dioxide (extruded)Urea

formaldehyde When your biomass processing can't take any

downtime.To be profitable, your wood and biomass pelleting

operation needs to run continuously, so you need equipment that

just keeps running. At CPM Wolverine Proctor, we have the world's

most durable equipment that requires minimum downtime for

maintenance. We have equipment that integrates drying into wood and

biomass pellet processing production lines with dryers that use

waste heat sources such as hot water, low-pressure steam,

and hot exhaust gasses from other processes. So if your

process needs equ

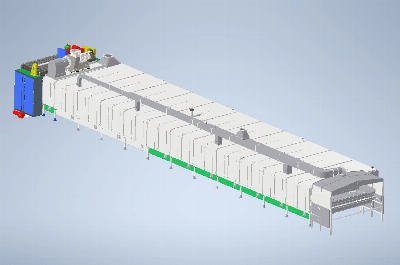

Related products about Thermoplastic Elastomer SEBS/Sbs/NBR Rubber Steam Heated Conveyor Belt Drying Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup