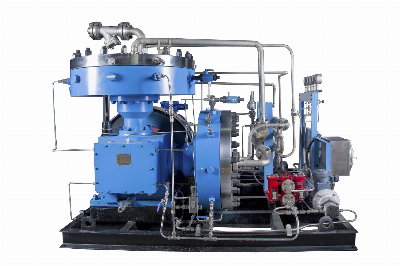

GZ Type Completely Oil-Free Diaphragm Compressor350bar

Corrosive-Proof No Leakage Ammonia Booster Corrosive Flammable Gas

CompressorMain StructureDiaphragm compressor structure is

mainly composed of motor, base, crankcase, crankshaft linkage

mechanism, cylinder components, crankshaft connecting rod, piston,

oil and gas pipeline, electric control system and some

accessories.Gas Media typeOur compressors can compress ammonia,

propylene, nitrogen, oxygen, helium, hydrogen, hydrogen chloride,

argon, hydrogen chloride, hydrogen sulfide, hydrogen bromide,

ethylene, acetylene, etc.(Nitrogen diaphragm compressor,bottle

filling compressor,oxygen diaphragm compressor)Advantages--No

leakage: the compressor membrane head is sealed by static "O"

ring. The O "ring is made of elastic material, with long

service life and no dynamic seal to ensure no leakage during gas

compression.--Corrosion resistance: the compressor membrane

head can be made of 316L stainless steel, the diaphragm is made of

301 stainless steel.--Small tightening torque: "O" ring seal,

can reduce flange bolt tightening torque, reduce shutdown

maintenance time.The compressor is consists of a three pieces

of diaphragms. The diaphragm is clamped along the surrounding area

by the hydraulic oil side and the process gas side of the process.

The diaphragm is driven by the hydraulic driver in the film head to

achieve the compression and transportation of the gas. The main

body of the diaphragm compressor consists of two systems: the

hydraulic oil system and the gas compression system, and the metal

membrane separates these two systems.Basically, the structure of

the diaphragm compressor is divided into two parts: the hydraulic

framework and the pneumatic force framework. During the compression

process, there are two steps: the suction stroke and the delivery

stroke.GV series Hydrogen diaphragm compressor :Structure type : V

typePiston Travel : 70-130mmMax Piston force : 10KN-30KNMax

discharge Pressure : 50MPaFlow Rate Range :2-100Nm3/hMotor Power :

2.2KW-30KWIf you want get the commercial quote , Customized is

accepted , Pls provide the following information to us :1.Flow

rate: _______Nm3/h2.Gas Media : ______ Hydrogen or Natural

Gas or Oxygen or other gas ?3.Inlet pressure: ___bar(g)4.Inlet

temperature:_____ºC5.Outlet pressure:____bar(g)6.Outlet

temperature:____ºC7.Installation location: _____indoor or outdoor?

8.Location ambient temperature: ____ºC9.Power supply: _V/

_Hz/ _3Ph?10.Cooling method for gas: air cooling or water

cooing?GZ series diaphragm compressor :Structure type :

Z typePiston Travel : 70-180mmMax Piston force : 10KN-90KNMax

discharge Pressure : 70MPaFlow Rate Range :0.5-500Nm3/hMotor Power

: 2.2KW-45KW GZ series diaphragm compressor parameter

tableModelCooling water consumption (t/h)Displacement (Nm³/h)Intake

pressure (MPa)Exhaust pressure (MPa)Dimensions L×W×H(mm)Weight

(t)Motor Power

(kW)GZ-2/31.02.00.00.31200×700×11000.52.2GZ-5/0.5-100.25.00.051.01400×740×12400.652.2GZ-5/13-2000.45.01.3201500×760×12000.754.0GZ-15/3-190.5150.31.91400×740×13300.754.0GZ-30/5-100.5300.51.01400×740×13300.73.0GZ-50/9.5-250.6500.952.51500×760×12000.755.5GZ-20/5-250.6200.52.51400×760×16000.654.0GZ-20/5-301.0200.53.01400×760×16000.655.5GZ-12/0.5-80.4120.050.81500×760×12000.754.0GZ-5/0.5-80.25.00.050.81400×740×12400.652.2GZ-14/39-450.5143.94.51000×460×11000.72.2GZ-60/30-402.1603.04.01400×800×13000.753.0GZ-80/59-650.5805.96.51200×780×12000.757.5GZ-30/7-301.0300.73.01400×760×16000.655.5GZ-10/0.5-100.2100.051.01400×800×11500.54.0GZ-5/80.25.00.00.81400×800×11500.53.0GZ-15/10-1000.6151.0101400×850×13201.05.5GZ-20/8-401.0200.84.01400×850×13201.04.0GZ-20/32-1601.0203.2161400×850×13201.05.5GZ-30/7.5-251.0300.752.51400×850×13201.07.5GZ-5/0.1-71.05.00.010.71200×750×10000.62.2GZ-8/51.08.00.00.51750×850×12501.03.0GZ-11/0.36-60.4110.0360.61500×760×12000.753.0GZ-3/0.21.03.00.00.021400×800×13001.02.2GZ-80/20-351.5802.03.51500×800×13000.95.5GZ-15/30-2001.0153.0201400×1000×12000.84.0GZ-12/4-351.0120.43.51500×1000×15000.85.5GZ-10/0.5-70.4100.050.71500×760×12000.753.0GZ-7/0.1-61.07.00.010.61200×900×12000.83.0GZ-20/4-201.0200.42.01400×850×13200.752.2GZF-42/120-3501.2421235900×630×8340,425.5GZ-7/0.1-61.570.010.61200×900×12000.83.0GZ-120/80-851.51008.08.51200×900×12000.84.0GZ-5/6-101.05.00.61.01200×700×11000.72.2GZ-7/50-3501.07.05.0351150×700×11000.453.0GZ-20/7-301.0200.73.01400×760×11000.754.0GZ-62/40-561.5624.05.61200×700×11000.453.0GZ-15/10-121.5151.01.21200×700×11000.53.0GZ-14/6-201.0140.62.01200×700×11000.52.2GZ-350/120-4501.03505-204502350×1850×11007.037GZ-936/8-8.32.09360.80.832100×1500×17002.015The

hydraulic piston (piston rod) is mounted to the crosshead. The

piston is sealed by piston rings and reciprocates in a hydraulic

cylinder. Each movement of the piston generates a fixed volume of

lubricating oil, thereby driving the diaphragm to reciprocate. The

lubricating oil acts on the diaphragm, so it is actually the

diaphragm compressed gas.The main functions of hydraulic oil in di

Related products about 350bar Corrosive-Proof No Leakage Ammonia Hydrogen Booster Compressor

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup