Product DescriptionProduct features1.Environmentally-friendly

technology instead of pickling.2.Remote control,easy operation.3.To

disperse the wire automatically,even,high effective

and lowl abor intensity for operator.

4.Ultra-low

emission:3mg/m³.5.Widely used in (high,medium,low) carbon

steel,alloy steel,stainless steel and

others.6.Good work environment and negative

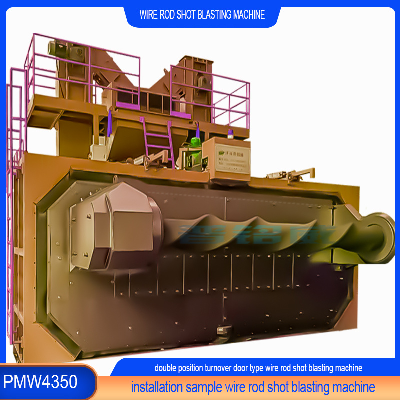

pressure within equipment.7.Can be customized

according to customer products.8.horizontal revolving door

type working principle for PMW4350 wire rod coil shot blasting

machineThe equipment is equipped with 6 sets impeller head

according to the characteristics of wire rod,which is

installed on the rear/side of the shot blasting chamber

to clear the wire with 60-90secs cast speed,.By using screw

horizontal conveying shot system, high strength belt

hoist, steel shot residue separation system, two-stage

purification dedusting system (inertia + filter ) and

(automatic + manual )HMI electric control system,it makes the

workpiece meets efficient shot

blasting requirements. Product ParametersApplication

range

fasteners,wire rope,spring,stainless steel,welding

rod,cold-heading wire,etc.Production capacity

20,000-80,000 each yearWire diameter

8-42mmEquipment size

6.6*5.5*6m(height on the ground)Wire loss

0.2-0.3%Derusting cost

about20-40RMB/TProduction efficiency

2-4coils/per

hourQPY4350 type double position horizontal rotation

wire rod shot blasting machine is a special equipment

which clean wire surface,which convert the

kinetic energy of the steel shot in high speed flying into the

impact force of workpiece surface to strip the oxide

and impurities on base metal by using the plastic deformation of

the base metal and its oxide, thereby cleaning the

wire rod surface thoroughly.The rust removal level

of surface after wire rod postprocessing reaches

Sa2.0-2.5.As the cleaning technology of this equipment,there

is no chemical reaction , its byproduct is

recyclable metal scrap, so this technology is

green environmental protection and no pollution.It has

the characteristics of economy, environmental protection and high

efficiency compared with the traditional pickling

method.Therefore, this equipment is widely used in the spring,

bolt, welding rod, welding wire, steel wire rope,steel

strand,etc. Which get more customers favor on smoggy

day

Related products about Horizontal Revolving Door Wire Rod Shot Blasting Machine for Steel Strand Wire

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup