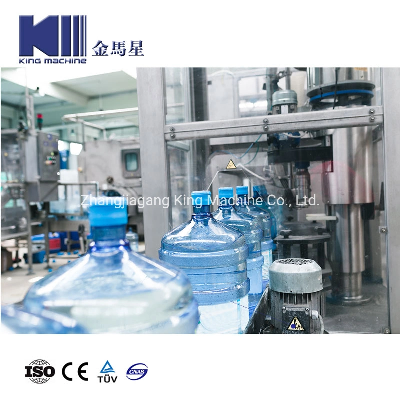

Automatic Mineral Water 5 Gallon Bottle Production LineProduct

Descriptionwashing filling capping mono-block Model QGF Barrel

Packing Production Line is affiliated production facility

especially for five gallons barrel packing production line .It is

especially suitable for producing mineral water, distilled water

,purified water .The machine is made of excellent stainless steel

,it is erosion-proof and it is easy to wash. Main electrical

appliances have applied SIMENS ,OMRON product .Pneumatic circuit .

has applied imported AIRTACT product. It is a automatic barreled

equipment with motor ,electric unit and air three in one . Model:

QGF-900 Filling Heads: 6 Filling Volume: 5 Gallon Size of Barrel:

ф276×490mm Capacity: 900barrels per hour Power supply: 380V, 50Hz,

Max power consumption 4 kw+ heating 9 kW the Power consumption is

only 3.5kw while the machine works as each electrical part starts

intermittently Volume of using water: Filling 18T/H;water washing

4.1T/H Structure type: gear wheel and rack transmission

intermittently; six filling valves Air source: pressure 0.5-0.6Mpa

Air consumption: 350L/M Overall dimension (mm): 5400×2100 ×2000mm

For rinisng part 3000*900*2200mm For Filling&capping part Total

weight:about 4.5Tons Cap elevator This machine is designed for the

5gallon cap uploader automatically. Detailed Photos Flow chart

:Barrel uploader--> Decapping machine-->Leakage

inspector-->External brusher-->Internal

brusher-->Automatic Rinsing,filling,capping(3in1)

machine-->Light checker-->Cap labeling machine-->Date

printerBarrel lifter-->Barrel lifter-->Barrel stacking

machineMachines of 20L Barrel Water Filling LineOutside brusher

washing machineLye flushing pump CHL4-30 0.55KW 1 CNPClean water

flushing pump CHL4-30 0.55KW 1 CNPMotor reducer NMRV063 i=15 0.55Kw

2 sets North MachineMotor reducer NMRV063 i=30 0.55Kw 1 unit North

MachineTravel switch JLXK1-411 1 OmronLow-voltage electrical

components, AC contactors, relays, etc. 1 set SchneiderBrushing

brushes 13 side brushes, 5 bottom brushes 1 set LiulinDimensions

3300 (L) × 1500 (W) × 1800 (H) mm High pressure washing

machineNumber of cleaning heads: 4Applicable barrel size: 5

GallonProduction capacity: 900 barrels / hour (washing time about

20 seconds) Rated voltage: three phase four wire 380VEquipment

size, length: 3640mm, width: 1230mm, height: 2500mmTechnical

parameters:Model: BG-900Technical parameters:Model: BG-900Number of

drawing lid: 2Dimension of barrel: Ф276×490Capacity: 900barrels per

hourSupplier: Compressive stress 0.6~0.8 Mpa, Tolerance

200L/MStructure type: cylinder movingOverall dimension (mm):

600×500×1800 Weight: about 0.5 TonCap Film shrink machineWith

continuous adjustable temperature, steam shrinker is suitable for

various types of shrink films and different speed requirements as

well. The use of thermal materials ensures high thermal insulation

and low energy consumption. Barrel stacking machine Pallerizer

arrange the finish products in 4*4 4*5, pick up, and pile up, save

many labors and whole action is made by PLC.Finish products is

controlled by PLC through signal lamp, pushed by cylinder, finish

the arrangement, up-down system come down, and gripper pick up the

bottles, turn 90degree, drop down on the center place. After

Sales ServiceNearly 15 years, King Machine has provided bottling &

packing equipments of liquid solutions to companies all over the

world, water bottling line, juice filling line, carbonated soft

drinks turnkey project, oil and soda water bottling line and

labeling and packing machinery. All your different requiremts King

Machine can always offer you the most professional solutions and

turnkey project. Company ProfileKing Machine Company

indtroducton:1. Installation, debugAfter equipment reached the

workshop of customer, place the equipment according to plane layout

we offered. We will arrange seasoned technician for equipment

installation, debug and test production at the same time make the

equipment reach the rated producing capacity of the line. The buyer

need to supply the round tickets and accommodation of our engineer,

and the salary.2. TrainingOur company offer technology training to

customer. The content of training is structure and maintenance of

equipment, control and operation of equipment. Seasoned technician

will guide and establish training outline. After training, the

technician of buyer could master the operation and maintenance,

could adjust the process and treat different failures.3. Quality

guaranteeWe promise that our goods are all new and not used.

They're made of suitable material, adopt new design. The quality,

specification and function all meet the demand of contract. We

promise that the products of this line could storage for one year

without adding any aseptic.4. After salesAfter checking, we offer

12 months as quality guarantee, free offer wearing parts and offer

other parts at the lowest price. In quality guarantee, the

technician of buyers should operate and maintain the equip

Related products about Factory Price Automatic 600bph 5 Gallon Bucket Big Bottle 19L 20L Bottled Liquid Pure Mineral Water Barrel Washing Filling Capping Bottling Packing Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup