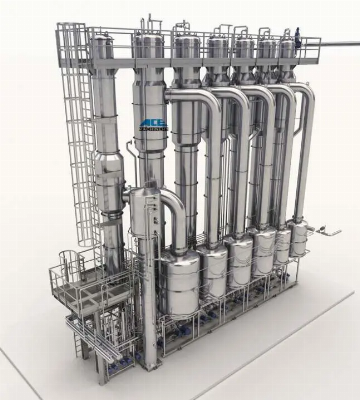

Custom Made Falling Film Evaporation Multiple effects Evaporator,

21 Years Of Experience. Reasonable Price And Best Service, Order

Online Now. CE Certificated Products. Please contact us for the

offer.Product DescriptionDescription:Single effect or multi effect

falling film evaporator is widely used in the concentration of

food, beverage, chemical, environmental protection, pharmaceutical

and other aqueous solutions. And can be widely used in related

industries waste liquid treatment. The equipment is operated

continuously under vacuum and low temperature. It has high

evaporation capacity, energy saving and low running cost. It can

maintain the original color, aroma, taste and composition of the

treated material. In food, medicine, food processing, beverage,

light industry, environmental protection, chemical industry and

many other industries have been widely used.System composition:The

effect of heating evaporator, condenser, separator, the effect of

heat pumps, sterilizer, pipe insulation, vacuum system, the effect

of feed pump and condensing water pump, operating platform,

electrical instrumentation control cabinet and the valve and pipe

system.Equipment Technology:By adopting the falling film

evaporation form, the equipment is used for concentration and

evaporation of fruit and vegetable juices and other heat sensitive

materials. The equipment is mainly composed of evaporator ,

separator, condenser etc. It is widely used for concentration and

dehydration in food, biology, pharmacy, chemical industry etc.The

evaporation system can be made up of

single-effect,2-effect,3-effect,4-effect,5-effect,6-effect

according to the property of compressed material and customer's

request.It can be also used together with the forced circulation

evaporator and crystallized to deal with the concentration and

product crystallization of high viscous and easy scaled material.It

is characterized by high efficiency of heat conduction, low power

consumption etc.It can widely use the waste heat (such as the

drier's hot air and flue gas), the remaining heat (of condensing

water, process water and flash steam) to form a waste heat

evaporation machine unit.Characteristics:Good Heat Transfer

Performance, High Evaporation Efficiency, Easy To Clean, In Line

With GMP Standards.Multiple stage design and saves energy;The

evaporation is under vacuum, the evaporation temperature is low, so

that it has good performance or heat sensitive material

evaporation.Advantages:1. The whole set system has reasonable and

beautiful design, stable operation, high efficiency, energy saving

and low steam consumption.2. Large concentration ratio, for the

last effect can be equipped with forced circulating evaporator,

which can make the materials of larger viscosity easily flow and

evaporate and shortens the concentrating time.3. The special design

can make modifications of effects easily to realize production of

various products.4. Low evaporation temperature. The heat quantity

can be fully used. The heating of materials is warm, so it is

applicable for concentration of heat sensitive materials.5. The

material is heated evenly in the pipe with high heat transfer

coefficient, in order to prevent the occurrence of "dry walls".6.

The materials and liquids are separated after coming into the

separator. The effect of separating is greatly improved, and it is

flexible to operate.7. The whole set equipment is quite compact,

and occupies little area, and the layout is simple and fluent, all

of which are the developing tendency of large whole set evaporating

equipment.8. The equipment is equipped with CIP cleaning system;9.

Type: From single effect to 8 effect;10. Capacity: 0.5t to

100t/hr11. Multi heating source: Steam/ conductive oil/hot

waterCustomer case New Zealand Single effect falling film

evaporator for blackberry juiceDouble effect forced circulation

evaporatorFour effect wastewater evaporatorSingle effect Falling

film evaporatorThree effect Falling film evaporatorPlate

evaporator MVR EvaporatorDescription:Mechanical vaporization

re-compression system, which is called MVR which principle is to

compress the second steam generated by evaporator by high

efficiency steam compressor; this process transfers electric energy

to heating energy and higher the pressure and temperature of second

steam. The second steam with higher temperature will be sent to

evaporation room to heat the product for evaporation. So the latent

heat of vaporization of the second steam can be circularly used.

Making use of less energy which is the mechanical energy of

compressor blade wheel as the compression heat pump, energy is

added into the heating medium and is circularly used in heating

process. Under this circumstance, no need to add first steam as

heating medium.MVR evaporator consist:Evaporator : The liquid

material inside the evaporator heated by steam for evaporation.

Choose different type evaporator according to different liquid

material features.Separator (crystallized):use t

Related products about Factory Price Multi-Effect Industry Concentrator Beverage Juice Ketchup Jam Meat Sauce Honey Milk Sugar Vacuum Forced Circulation Mvr Falling Film Evaporator

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup