I. Main technical parameters of regenerative combustion system 1,

aluminum smelting furnace uses: aluminum ingot, recycling aluminum

waste smelting, heat preservation and alloy composition adjustment

2, the furnace specification: rectangular or circular aluminum

melting furnace, capacity of 10 tons +5% 3. Fuel: natural gas

or oil 4. Pressure in front of fuel furnace: pressure in front of

furnace 8 ~ 12kPa; The usual pressure is 10kPa 5. Feeding mode:

manual or forklift feeding in batches from the furnace door 6.

Working temperature of furnace: normal working temperature ≤1150ºC,

maximum working temperature 1200ºC 7, liquid aluminum oven

temperature: normal oven temperature 680 ~ 720ºC, the highest 750ºC

8, melting period melting rate: 2 ~ 4t/h (varies according to the

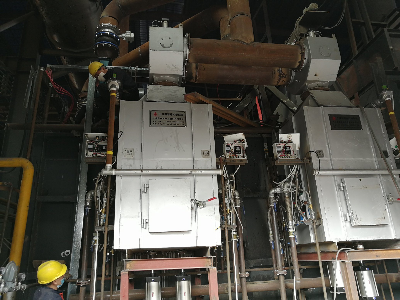

type of raw materials) 9, burner type and number: upper type

regenerative double flame burner, one pair of two with 4 sets of

main burner 10. Burner installation position: centered on the side

wall of aluminum smelting furnace (or symmetrical installation on

both sides of the furnace door) 11, heat storage body material:

diameter 25mm to 50mm high aluminum solid ceramic heat storage ball

12, burner maximum combustion capacity: 2000kW, maximum energy

consumption 220m3/h natural gas, firepower regulation depends on

the gas electric regulating valve opening double gas solenoid valve

combination switch, to realize the automatic operation of fire,

fire and small fire. 13, air preheating temperature: less than

1000ºC flue gas emission temperature: less than 180ºC 14,

temperature measurement mode: furnace temperature and exhaust

temperature automatic measurement, liquid aluminum temperature

manual measurement 15, temperature control form: PLC automatic

control furnace temperature and exhaust temperature, display and

record 16, furnace pressure control mode: rely on induced draft fan

frequency conversion regulation of flue gas flow, micro positive

pressure automatic control of furnace pressure 17, heat load

regulation mode: according to the set air-fuel ratio parameters,

automatic control of gas flow and combustion air flow of each gear,

to achieve automatic regulation and control of heat load. 18.

Control idea of air-fuel ratio: First of all, according to the

process needs, independent selection of fire, medium fire, small

fire (melting file, temperature file, heat preservation file),

automatic control of electric gas regulating valve opening double

gas solenoid valve combination switch, real-time monitoring of gas

flow and combustion air flow, according to the set air-fuel ratio

parameters, automatic control of blower and induced draft fan

optimal operating frequency, Automatically match the gas flow at

the corresponding gear, truly realize the automatic control

operation of air-fuel ratio, and effectively avoid the influence of

heat storage ball blockage and naked eye judgment error on flame

regulation. 19. Gas flow regulation mode: The gas flow of the whole

system is operated by electric regulating valve and double gas

solenoid valve combination switch, and the gas flow value

(firepower) of three gears is set in advance. 20, combustion fan

and flow regulation: high pressure fan model 9-19-5.6A, air volume

2600m3/h, motor power 11kW. The combustion air flow is monitored by

air flowmeter in real time, and the frequency converter is adjusted

automatically. 21. Induced draft fan and flow regulation: High

pressure fan model 9-19-6.3D, air volume 3200m3/h, motor power

18.5kW. The gas discharge flow rate is automatically adjusted by

frequency converter to keep the furnace pressure stable. 22,

compressed air consumption: 0.3m3/min, 0.6 ~ 0.8MPa 23. Installed

capacity of power supply: 380/50Hz/3 phase total 30kW 24, energy

consumption index: ensure energy saving more than 30% than ordinary

combustion system, melting furnace per ton of aluminum energy

consumption less than 500,000 kcal/ton aluminum (the total energy

consumption of all aluminum ingot melted to 660ºC aluminum water is

not higher than 46m3 natural gas per ton aluminum ingot), better

than the national special furnace energy standards. Or the energy

consumption of 70% clean bulk waste +30% aluminum ingot melting to

660ºC aluminum water is not higher than 52m3 per ton of raw gas,

and the energy consumption of melting to 720ºC aluminum water is

not higher than 57m3 per ton of raw gas. 25, energy consumption

testing standards: according to the "JBT-50168-1999 aluminum

melting Fuel furnace energy consumption grade" standard

implementation. 26. Safety protection measures: Outage and

automatic recovery of furnace temperature exceeding the standard,

forced reversing and outage alarm of smoke exhaust temperature

exceeding the standard, interlocking of furnace door switch and

combustion system, automatic flame monitoring flares out and false

alarm protection, automatic protection of ignition air, combustion

air, compressed air blocking under pressure leakage, automatic

outage of furnace pressure excee

Related products about 2000W Oil or Natural Gas Regenerative Burner

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup