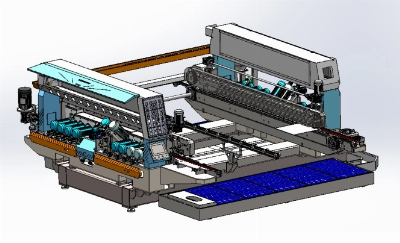

High Quality Glass Double Edging MachineMACHINE FEATURESThe

basement and the main body are of welded strong structure with heat

treatment, sandblasting and painting process, so that the working

quality and precision ensured with less vibration and deformation,

also anti-rust process ensure machine a longer working life.The

conveying of glass and adjustment of width are controlled by servo

motor, which ensures the working precision and less maintenance.The

convey of the machine is adopted of gear box, gears are working

with oil lubrication, its of simple structure so that the glass

conveying is smooth, also easy for maintenance.The protection cover

is made of stainless steel for ball screw and guide, this avoid

water and glass particulars falling into the screw and guide, so

that greatly reduce the rust and maintenance. The movement of the

machine is automatically lubricated with oil pump, oil is well

distributed and evenly, this will ensure machine of good working

condition and longer lifetime. SPECIFICATIONSCOPE OF

SUPPLYGlass Double Edging Line Model Number: HEM2450 +

HTT5033 + HEM2433Remarks: Photo and data contained in this

offer is subject to final configuration and updateintroduction OF

production lineComponents and principlesThis line is launched to

satisfy the market and customer's requirement of jumbo glass,

which developed on the basis of our reliable glass double edging

machines with connecting equipment for increasing automation and

saving labor cost. This line is composed of following

equipment:Double Edging Machine 5000mm: HEM2450"L" Shape

Transfer Table 5000X3300: HTT5033Double Edging Machine

3300mm: HEM2433This specialized line is designed for grinding

4 edges of flat glass with arris & Low-E deletion automatically,

rough grinding, fine grinding and polishing have been finished at

one processing travel. With pneumatic positioning, timing

belt conveying to realize fast positioning, precisely speeding and

smooth conveying; glass width is adjusted via Servo motor, speed is

adjusted via frequency converter, with encoder monitoring to ensure

the precision. The line is adopted PLC control, the input and

modification of parameters are intuitive, convenient and highly

automated. This is high efficient equipment with high output, less

labor consumption, it's a perfect machine for mass glass

production, Our machines are manufactured under strict standard and

techniques, Reliable, high efficiency, stability and intelligent is

the main characters of our machine, which help our customer to

enlarge the business will reliable quality. Work flow:The

glass data will be input to PLC of double edger,

then the glass will be transferred to 1st double edging

machine HEM2460 for processing of 2 edges, the direction of

glass flow will be changed at 90°degree when glass arrived transfer

table HTT6033 and then glass will be transferring to

2nd double edger HEM2433 for processing of other 2 edges;

then glass comes to the washing machine for washing and drying

process; at the last glass will be unloaded. this double

edging line is compatible with glass tempering furnace, glass

screen printing, laminated glass line, and so on.CONFIGURATION OF

production lineHEM2460 + HTT6033 + HEM2433 DOUBLE

EDGING LINE ITEMSpecificationsGrinder quantity

(pcs)

24 +

24 (12pcs each side)Working speed (m/min)

3~6

mm: coarse grinding: 12-15m/min 8~12mm: fine grinding:

8-10m/min15~25mm: fine grinding: 4-6m/minThickness of glass

(mm) 3-25Glass

sizes for

HEM2450 (mm) 400-5000Glass

sizes for

HTT5033 (mm) 400*400-5000*3300Glass

sizes for

HEM2433 (mm) 400-3300Parallel

tolerance (mm/m)

≤0.2Diagonal

tolerance (mm/m)

≤0.5Finished

product rate≥99%Installed power (KW)

150Air

pressure

(Mpa) 0.6Water

pump flow(cbm/h)10Total weight (Kgs)About 20000Overall dimension

(mm)About 16500*8000*2000Power supply

220/380/415V,

50/60HZ or customizedGRINDING WHEEL LEGEND OF 1ST &

2nd EDGING MACHINEMotor No.123456789101112Motor

power(KW)432.22.22.22.22.22.22.22.22.22.2Motor

speed(RPM)284028402840284028402840284028402840284014002840Wheel

configurationDiamond

ResinPolishResin Polish 100G140G180G240G240G10S4010S40240G10S4010S60CE3BK46 CONFIGURATION

LIST NoParts Name

Original/Brand

1Grinding

Motor CDQC/ABB

2Timing

belt

BABEILI 3Linear

Guide

HIWIN

Related products about High Speed 4200mm Glass Double Edging Machine Compatible with Cutting, Drilling, Washing, Printing, Tempering, Laminating, Engraving, Sandblasting

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup