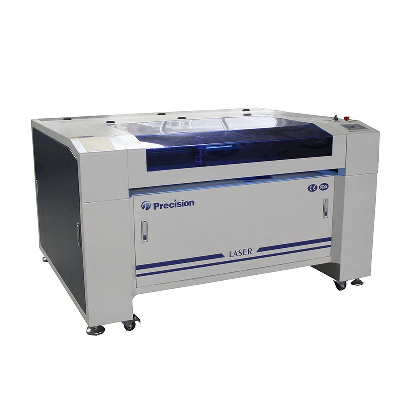

1390 60w 80w laser subsurface engraving machine Detailed

parts Introduction of machine cabient 1.Adopt the frame

structure to weld the plates and sections into a whole, high

welding strength and goodanti-seismic performance;2.All the plates

and sections are made of galvanized products to

prevent moist and rust during wetconditions, especially

at sea.3.Galvanized sheet welding difficult, long working hours,

expensive materials, manufacturing costs higherthan ordinary

steel;4.Worktable thickening, high strength and the use of the

entire board to ensure the installation of flatness; 5.The

support part of the machine's bottom welded ribs plate to ensure

support strength;6.It is easy to move and reliable to support with

the use of universal wheel and foot support.7.The bottom of the

machine welded ribs, and the gap between the ground large enough,

hydraulic lift truckcan easily enter from below to facilitate

loading and unloading Reci laser tube Control box

RD controller HIWIN rails

1. Maintenance free-No need for

frequent periodic lubrication or automatic lubrication

systems.2. Long service life,

long-term automatic maintenance of the track surface lubricating

film protection.3. Curtailing

lubrication cost.4. No oil leakage

concern, easy for cleaning.

Standard Configuration (1)Working area is :1300*900 mm

(2)Reci W2 (80-100w) Laser tube Reci W4 (100-130w) Laser

tube Reci W6 (130-150w) Laser tube Reci W8 (150-180w)

Laser tube (3) RDC6442/6445 control system (4)YAKO stepper

motor YKD3505M-DK-B1 and driver YK368-826G(you can also choose

Leadshine 573S15-L motor and 3DM580 driver)(5) HIWIN square

rail (6)American 26 Mirrors :Three Reflection mirror and

one focus lens (7)Blade table ( Alternative Honeycomb table

)(8)Shanghai Fulo belt (9)Water pump or S&A Industrial

Water Chiller CW3000 CW5000 CW5200(10)Red light point(11)Water

protection switch(12)Open cover protection (the machine will stop

working when open cover) (13) Exhaust Fan 550w (14)Air

Pump (15)Galvanized sheet machine frame which is damp-proof

and anti-rust (16)All acrylic cover (you can see machine

working clearly) (17)Tool box MAIN FEATURES: #

Available to nonmetal material# With auto and DSP following up

system to ensure high

accuracy.Offline control system can not only work without computer, also connect to USB.#

Ruida 6442

control panel in English,Portugese,French,Turkey,German, convenience of operation control.#

With RECI laser tube,long lifetime more than 10000

hours.# Honey comb working tableBlade working table for laser cutting. Which meet the need of diversified laser procession.#Import HIWIN guide rail with high engraving precision.# Imported Singapore lens and Morris, with good quality and ability of reflection and focusing, long working life.#Red light position system realize the exact position and frame of machine is stable, ensure the precision.

Technical parameters of 1390 laser cutting machine

Packing size1840*1340*1300mmLaser tubeco2Laser TubeRECI laser tube

Or EFR laser tubeControlling systemNewest DSP control

systemFunctionCut/ Scan/ EngraveTable surfaceBlade table/Honeycomb

tableOptical systemAmerican26 lens and mirrorsProtection

systemWater protection switchCutting speed0~24000mm/minEngraving

speed0~60000mm/minResolution ratio4000dpiGraphic format

supportedBMP, PLT, DST, DXF, AI, GIF, PCS, TGASoftware

supportedCorelDraw, Photoshop, AutoCAD, TAJIMAPower

supplyAC220V/50/60Hz or AC110V/50/60HzApplicable

materialAcrylic, crystal, glass, ceramic, marble, cloth, fabric,

wood etc.X,Y TravelingPositioning accuracy ±0.01/300mmX,Y

Repositioning positioning accuracy±0.01mmTransmissionFulong belt

transmissionRailTaiwan ABBA/Hiwin railsMotorsServo/Stepper

motorsDriversYako Max powerAbout 1kwMax working

speed24000mm/minInterfaceUSB Offline and WIFI

Applicable materialswood,bamboo, jade, marble, organic glass,

crystal, plastic, garments, paper, leather,rubber,ceramic,towers,

glass and other nonmetal materials. Applicable

industriesadvertisement, arts and crafts, leather, toys, garments,

model , building upholster,computerized embroidery and

clipping,jeans, packaging and paper industry. Packing and

shippingPackage and shipment of 1325 laser cutting machine

# Delivery period: 7-15

working days after getting the deposit # Package method:

water-proof plastic film for inner package, standard plywood case

for outer package # shipping method: by sea # we have

ship forward to help us transport the machine Service

of laser cutting machine# warranty: 12 month period, in the case of

part damage (excluding human-damage),the part shall be replaced

free of charge. Out of the warranty, all parts can be replaced with

agent price. # all machine have strict inner quality control

in the whole process of the machine production# CE

certificates # have 2 skillful service teams, 24 hour online

to service you, once there is a question from the customer,they can

give feedback by email/skype/

Related products about 1390 60W 80W Laser Subsurface Engraving Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup