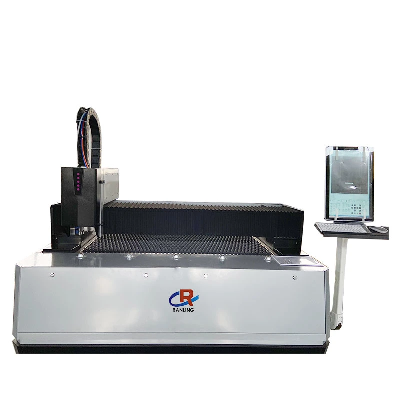

Product DescriptionFiber Laser Cutting Equipment is suitable

for metal cutting with Stainless Steel Sheet(tube), Mild Steel

Plate(tube), Carbon Steel Sheet(tube), Alloy Steel Plate, Spring

Steel Sheet(tube), Iron Plate(tube),, Galvanized Iron(tube),,

Galvanized Sheet, Aluminum Plate(tube), Copper Sheet(tube),, Brass

Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate,

Metal Sheet, Metal Plate,Tubes and Pipes,

etcPlate Welding Bed1.It is welded by a piece of

steel plate.2.The first choice of most laser manufacturers. After

the aging annealing process is achieved, it can be used for 20

years. The machine bed must be selected for high-power machines.

The production cycle of the plate welding bed is relatively short,

easy to organize production, high cutting efficiency, and long

service life.A.Brand: Raytools/WSX/Precitec/OSPRI or others brands

customer's requirements;If it is mainly thin plates, below 3000w,

recommend:WSX/RaytoolsB. Automatic cutting head.It improves the

processing efficiency of the fiber laser cutting machine - the

thick plate piercing time is reduced; when processing workpieces of

different materials and thicknesses, the machine can automatically

and quickly adjust the focus to the most suitable

position. The automatic focus will reduce the phenomenon of

overheating due to overheating of the plate. Laser

Power:

500W/1000W/1500W/2000W/3000W/4000W/6000W/8000W/10000W/12000W/15000W/20000W/30000WBrand:

IPG/RAYCUS/MAX/or others brands customer's The higher the power,

the thicker the cutting thickness.Control system: CYPCUTGeneral

functions include graphics processing, parameter settings, custom

cutting process editing, nesting, path planning, simulation, and

cutting process control.Supports speed-dependent power adjustment

and can set separate lead-in line speeds.The material process

library function allows all process parameters to be saved for

reuse of the same material. Servo and

MotorBrand:Yaskawa, Panasonic, Mitsubishi,quality

assurance 2.Rack:Brand: YYC HIWINReduce frictional resistance

and improve high-speed performance of linear guides. What's

the difference between fiber laser, YAG laser and CO2 laser working

on metal material?Laser sourceFiber laserYAG laserCO2 laserBeam

qualityBestGoodPoorSpeedFastSlowSlowElectrical

efficiencyHighCommonLowReliabilityBestGoodPoorMaintenanceFreeComplexDifficultRemote

processingFreeComplexDifficultInitial

investmentHighCommonLowProduct Parameters Model RL3015 RL-4015

RL-4020 RL-6025 RL-8025 Working Area 3048*1524mm 4050*1524mm

4050*2030mm 6060*2530mm 8080*2560mm Laser Output Power

20000w/15000w/12000w/10000w/8000w/6000w/4000w/3000W/2000W/1500W/1000W/500W

Positioning accuracy ±0.05mm Repositioning accuracy ±0.03mm Max.

linkage speed 120m/min Max. acceleration 1.5G Detailed

Photos Quality Inspection:Cutting

Samples:Application Fiber Laser Cutting Machine is widely used

in manufacturing Billboard, Advertising, Signs, Signage, Metal

Letters, LED Letters,Kitchen Ware, Advertising Letters, Sheet Metal

Processing, Metals Components and Parts, Ironware, Chassis, Racks &

Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel

Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts,

Nameplates, etcExhibition&CertificationsCompany ProfileFounded

in 2011,Ranling Intelligent Equipment Technology Co., LTD is a

manufacturer specialized in the research development and production

of laser cutting machines, laser welding machines and CNC Aluminum

profile cutting machines for windows and doors. On the basis of

technology development, we have taken in a group of experienced

personnel who are talented in senior management marketing and

skills of producing. We are located in Jinan Shandong province, one

of the best professional machine industries in China. All the

products are certificated by CE and comply with international

quality standards and are greatly appreciated in a variety of

different markets at home and at abroad.CNC Fiber Laser Cutting

Welding Machine for Metal After Sales Service1. 1

year Guarantee for the whole machine.2. 12 months Guarantee and

free spare parts supply during this period.3. 24 hours on line

service4. 3-7 days lead time5. We will provide the Instruction

Book, Operational manual and Training Video6. Provide technical

support for the whole lifetime on line7. TT/Ali Trade Assurance

paymentPackaging & ShippingFAQ:1.How to choose the right to

for me? A : Tell us the following information1) Metal material

for welding: choose the most suitable model.2) Laser welding metal

material thickness: the power of the laser generator.3) Line of

business: We sell many products and advise on this line of

business.2.Do you have CE document and other documents for customs

clearance?A: Yes, we have CE, Provide you with a one-stop

service.At first we will show you and and after shipment we will

give you CE/Packinglist/Commercial Invoice/ Sales contract for

customs clearance.3.If we want to learn how to operate th

Related products about 1000W 3000W 4kw 6kw Fiber Laser Cutting Machine Iron Plate Laser Cutter

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup