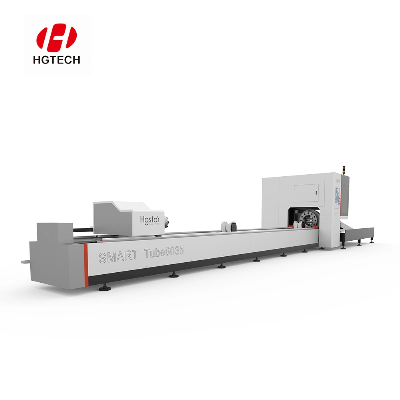

SMART TUBE6015 Laser Tube Cutting MachineProduct DescriptionSMART

TUBE 6015 laser tube cutting machine is manufactured by HGSTAR

according to international export standard. This series of

equipment is the preferred model for the metal tube processing

industry. It has strong cutting capacity, "flying" cutting speed,

ultra-high stability, high-quality processing, extremely low

operating costs, and super high adaptability.The SMART TUBE 6015

laser tube cutting machine can perform high-speed, high-quality

laser cutting on round tubes, square tubes, rectangular tubes, and

oval tubes. The cutting section has no burrs or slag. The cutting

shape can be diversified for any shape requirement.The SMART TUBE

6015 laser tube cutting machine adopts World's highest

efficiency and advanced structure, motor gear rack drive,

transmission components such as gearbox, guide rails and rack and

pinion, which are all well-known foreign brands. It is featured by

stable structure, good rigidity, light weight, and high dynamic

response. It is a high-performance laser tube cutting

machine.Product ParametersEquipment ModelSMART TUBE6015Chuck

diameterΦ20mm~Φ230mmMaterial typeCarbon steel or round tube, square

tube, rectangular tube, oval tube, etc ofstainless steelTube

feeding length6000 mmMaximum blanking length of the tube1500

mm,3500m(Optional)Maximum single tube weight30Kg/mLaser cutting

thicknessCarbon steel 1-10mm (thickness and material are

related to laser generator)Feeding methodManualXY Positioning

accuracy±0.05mmXY repeat positioningaccuracy±0.03mmA,W axisInfinite

rotationProduct main configuration listItemSpecifications and

ModelsBed, beam, Z axis box.Linear Guides: Taiwan TSC, Taiwan

Silver Rack: Taiwan APEXLoading systemArtificial feedingLoading

rackHGSTAR supporting modelsChuck max sizeΦ230mmNumber of

chucksStandard 2 chuckLaser headRaytools standard cutting

headHeight tracking sensorBCS100E Height adjusterCNC

systemCyptubeServo motorYaskawaOperationsystemWINDOWSMonitor19-inch

screenControl systemLaser tube cutting control systemControl

cabinets, consoles, handheld operating

units,etc.HGSTAR supporting modelsLaser sourceRaycus

1000WCooling systemHGSTAR supporting modelVentilation systemHGSTAR

supporting models(No dust removal function)Gas distribution

systeSMClaser cutting special functionCNC Control System (Tube

Pro FSCUT3000)>The control system consists of numerical control

systems, PLC and control cabinet.etc.>HGSTAR adopt the control

system develop based on TubePro FSCUT3000, dedicated for laser

cutting, FSCUT3000, have modular, openness and unity structure,

easy to operate, programming, it's a kind of visualization and

provide a function for all technology innovation platform.Handheld

Operating Unit>Integrated digital input, digital output, digital

potentiometer signal, MPG, etc.>Very convenience during worker

debugging and operation.Software generated

processing code>CAD/CAM software can read 3D graphics that

transformed from SolidWorks drawings, and can also draw standard

tube cutting graphics in CAD/CAM software.Artificial

feeding system>Manually transport a single tube to the

machine bed.>The sensor on the bed automatically senses

the tube and execute the mounting program.Security

Protection Function>Digital interlocks and safety devices

are installed in the laser to ensure that the laser is not turned

on for safe operation and maintenance.>The perimeter of the

cutting area is protected to protect the operator from motion

system and laser reflections.FeatureSpace Leapfrog and Flying

CuttingThe technology helps to minimize the moving path of cutting

head by omitting repeated lift and fall, therefore, cutting speed

is improved beyond doubtFeeding and Guiding FunctionSystem can

automatically hold and guide the single tube by the main chuck.

During the cutting process, the support frame can lift theChucks

are suitable for different tubeThe chuck canself-center.The tube

end does not need to be polished, tube end with burrs is

automatically cut after feedingCut Conventional Tubes,Profiles

andSpecial-shaped TubesTUBE6015 can not only cut conventional tubes

like round, square and rectangular tubes, and profiles like

channel, angle and H-shaped steels, but also cut special-shaped

tubes easily like triangular, concave, L and C-shaped tubes,

etc. SampleApplicable to cutting carbon steel, stainless

steel, aluminum, brass , alloy metals, etc.After Sales

Service 1. Warranty period: From the acceptance qualified

date, the warranty period will be 1 (one) year, but in any

case, not more than 13 months after B/L date. Seller is responsible

to offer free fittings in these years (except consumable part.)

Buyer has to send the damaged fitting to sellers. After the

warranty, we will also provide favorable service of long term

technical supports and spares supply to ensure machine's stable and

continuous running.2. The artificial damage in the warranty period

and damage after warranty period, Seller offers paid

service. 3. The Seller

Related products about High Power 1000W 2000W 6000W CNC Pipe Sheet Tube Fiber Laser Cutting Machine High Quality Laser Pipe Cutter for Metal Stainless Carbon Steel

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup