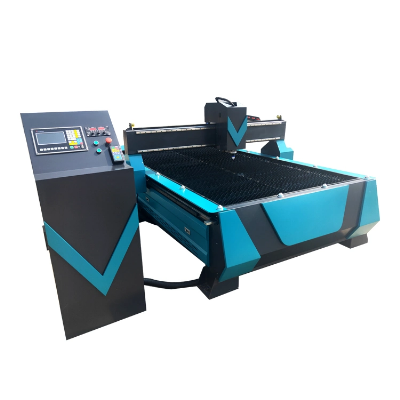

200A CNC Plasma Cutting MachineProduct DescriptionApplicable

Materials Of Plasma Cutting MachineCutting stainless steel, carbon

steel, mild steel, alloy steel, galvanized steel, silicon steel,

spring steel, titanium sheet, galvanized sheet, iron sheet, inox

sheet, and other metal sheet, metal plate etc.Applicable Industries

Of Plasma Cutting MachineMachinery parts, metal arts , electrics,

sheet metal fabrication, electrical cabinet, kitchenware, elevator

panel, hardware tools, metal enclosure, advertising sign letters,

lighting lamps, metal crafts, decoration, jewelry, medical

instruments, automotive parts and other metal cutting

fields. Detailed PhotosThe structure and configuration

list 1. seamless welding machine body2. 1500*3000mm working

area3. Independent control cabinet4. STARfire control system5.

Automatic Torch height controller6. Starcam software7. 2GB

processing file8. high precision square guide rail9. HUAYUAN Plasma

Generator 10.Leadshine servo motor11.Multi-function tool

box12.Efficiency exhaust smoke system13.Easy feeding slide material

system14.High quality soft electricity cable can be bend for 1.5

million times15.15 sets of nozzle electrodes16.All the necessary

parts for machine working17.Wireless control

handle18.Electromagnetic collision prevention function19.Red light

positioning function20.Automatic oiling system Product

ParametersX,Y working area1500*3000mm / 2000*3000mm /

2000*6000mmZ working area150mmMachine Power16kw Working

voltage380V / 3 PhaseReposition precision0.02mm

Processing precision0.1mmMaximum cutting

speed12000mm/minTorch Height control modeAutomatic Plasma power

supply63A 100A 120A 160A 200AControl systemSTARfire Motorsservo

motor SoftwareStarcamPlasma Air PressureMax.0.8MpaWorking

Temperature-10°C-60°C. Relative Humidity, 0-95%.LCD Display

Dimension7 InchesWe do this line many years, have rich experience

and professional knowledge, will let you get the most suitable

machine with the right configuration. This ability can let you

avoid many mistake and avoid some trouble. Other factory usually

lack this experience, and bring some trouble for the real customer.

If use the plasma cutting machine to cut the the thick meal,

have to use the arc height adjust system, while our height adjust

system use the high sensor, one minute can send out 12,000 signal

per minute, while other height adjust system usually send out 10000

signal per minute, so our cutting quality more better than other

factory and cutting speed a litter faster than the same power

plasma source. we equipped the two fan for take the cutting

smoke out from the room, front fan will blow to back, the back fan

will exhaust the smoke out from the machine and out from the room.

This way, will efficiency to let the workshop in the good

environment. While other factory does not have this fan or only

have one. All our machines have to be checked three times,

then allow to send out ,and finally will put one 8GB flash disk

into the package, when the customer received the machine, can easy

check the video from the 8GB flash disk ,then do the easy

operation, in the video nearly like hand by hand do the teaching

job, so can let the customer in the shot time to let the machine

create the profit. While we also have the video platform, after you

purchase the machine, we will give you one password, then you can

easy to get the efficiency "after-sell service" from the internet.

While other small factory usually, only check one time for the

machine, and no 8GB flash disk, and no video platform, then it is

hard for you to get the good after-sell service. we will

free provide 2G processing design (USD 320) and Australia

professional metal cutting software for you, in the 2G processing

design have thousand beautiful graphic, after you get the machine,

you can let the machine do a lot of beautiful work, while no need

find the engineer to help you to design. Machine structure

is designed by famous mechanical professor, to add many columns for

each bean. So that the machine body can bear more weight for large,

thick metal sheets without deforming. But some small factories will

not add these parts for saving cost, their machine is easy to

deform for thick metal.Related ProductsMetal Sheet Fiber Laser

Cutting MachineMetal Tube Fiber Laser Cutting MachineHandheld Fiber

Laser Welding Machine Packaging & ShippingCertificationsOur

plasma cutting machine have CE certificates , all electric drawing

and quality is suitable European standard .After Sales Service*3

years guarantee of the whole machine and we give lifetime

maintenance free of charge. *Free training to make sure you

master the operating of machine at our factory. * 24

hours online services through Whatsapp, Skype, Email or on the

phone. *Engineers available for overseas training and

after-sale services. * Friendly English version manual

and operation video CD disk.Company ProfileKnoppo

Automation is one of the world's leading manufacturers of

high-tech industr

Related products about 1530 Best Price Heavy Duty CNC Metal Plasma Cutting Machine for Stainless Steel Carbon Steel

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup