VIDEO https://youtu.be/krmfPh8sjNk

it is cutting 35mm thickness

SShttps://youtu.be/885VleSddOY

gantry modelhttps://youtu.be/32PIfcPFI1w

portable

model https://youtu.be/2vhEsQtHCuo

plasma +drillhttps://youtu.be/BqbOSwf4tO0

huayuan 200A power is cutting 22cm

stell https://youtu.be/9NH1s1NgUvU all

machinecan be with

flame, https://youtu.be/bzyGWsC3MoU cut

10mm steel https://youtu.be/X-ge-GJMaww

cut pipe with rotary

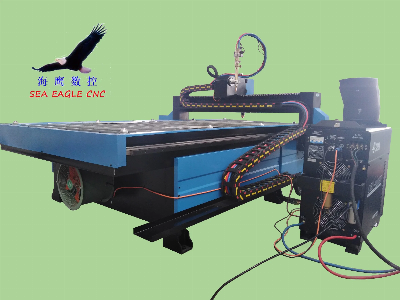

Model2040Working

siz (X*Y*Z, mm)2000*4000*150mmHeighten system ourself product,

can't be arc breakingMachine structureHeavy duty ,Channel steel

lathe bed,serrated working table,water sink,auto exhaust fanX Y20

square guide rail,helical rack drivingPower sourceHuayuan

160A (0-25mm)Working speed12m-15m/minCutting

Thickness0-25mmPrecision0.05mmPositioning

precision>0.02mmRepeatability0.02mmCommand codeG codeWorking

voltageAC380V±30V, 50HzMotorStepper motor 450A Operating

environmentWindows98/XP/7DriveLeadshineControl

systemStarfire system with height control

sensorOutside2200*3600*1600mmTable height750mmNet

weight1600kgsoftwarestartcam water sink170mm, stainless

steelWith Air compressor.yesTechnical specification:1, CNC plasma

and pipe cutting machine is a precision mechanical

transmission device with thermal cutting technology combined with

a high efficiency, high precision, high

reliability. With inimitable man-machine interface,

operation is simple and easy , can cut out various shapes of

complex sheet metal quickly and accurately, especially suitable for

automatically, thin steel non-ferrous metals, stainless steel and

carbon steel plate cutting. It adopts an integrated modular design,

quick installation, convenient movement.2, the whole bed adopts

steel structure welding after finishing, whole temper, sufficient

to eliminate welding stress, stable and reliable performance. The

beam and the end beam used aluminum after finishing, good movement

performance. Y axis with bilateral synchronous drive system.

To ensure the machine speed and accuracy.3, X and Y axis

guide rail with domestic or imported linear guide rail, high

precision, good guide. Drive rack, gear by the professional

manufacturer of custom, The surface carburizing and quenching, high

precision.4, LCD screen, all of the use of Chinese /english

characters display. Below the display show the operation method at

any time, so the operator only needs simple training, the operation

can be carried out, using very easy to understand.5, the drive

system can choose servo drive or stepping driving, according to the

requirement of customers can choose the world's top brand from

Japan -- Panasonic AC servo or stepper motor drive, can be more

stable running speed, a wider range of speed transmission,

short acceleration time;6, the machine has a smoke dust

removal device and exhaust type unique cutting worktable and the

slag storage device, to create a good working environment.7,

With high response sensitivity torch height control,it can adjust

automatically choose the best cutting distance, in order to ensure

the accuracy of the work piece cutting effect .8, according to user

requirements can be equipped with a variety of plasma cutting

power supply, to meet the different metal materials. /* March

10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Automatic Torch Height Controller Carbon Steel Sheet Pipe China CNC Plasma Cutter

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup