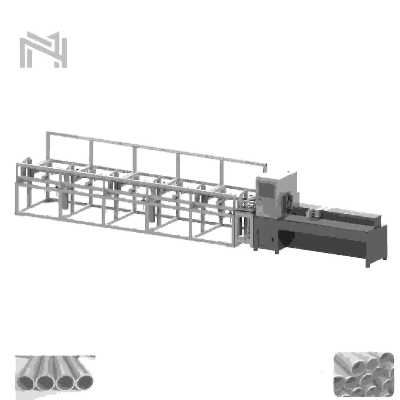

Product DescriptionBasic Info.Due to the continuous

improvement of social living standards, consumers put forward more

requirements on the appearance quality and style of products.

Traditional cutting methods can not meet the needs of the modern

market. The application of laser cutting technology not only

improves the working efficiency of processing, but also makes the

processing process more exquisite. At the same time, it meets the

technical requirements of high speed and high precision of laser

cutting machine, and solves the problems of slow operation speed,

difficult maintenance and inflexible design of traditional metal

cutting equipment. Product ParametersStandard

configurationNo.ItemBrand/Origin1Fiber laserChina2Laser cutting

headChina3CNC system (including control

software)China4chuckChina5servo motor and driverJapan6Precision

reducerJapan7X and Y gear rackTaiwan YYC8Ball screwTaiwan9Linear

guideTaiwan10Pneumatic systemJapan11Laser chillerChina12Electrical

componentFrance/China13Electric control cabinet and operating

stationChina14Machine bedChina15Beam (Pipe cutting type)China16Air

compressor (optional)ChinaProduct Parameters Model

No.NK40NK70NK90NK120Maximum processing

rangeΦ40mmΦ70mmΦ90mmΦ115mmMaximum raw material

length6200mm6200mm6200mm6200mmLaser power1-3KW1-3KW1-3KW1-3KWPipe

cutting precision±0.2mm±0.2mm±0.2mm±0.2mmExternal size (excluding

material

rack)2700×910×1810mm2700×910×1810mm2700×910×1810mm2700×910×1810mmFeatures

1.Fast Cutting speed, high efficiency, save labor, improve the

efficiency of cutting pipe and material.2.Easy to operate, low

requirements for the operator's skills, automatic feeding,

different specifications of pipe switch simple and convenient.3.The

equipment has slag pumping function, no burr in the incision, no

slag hanging, no burning Angle.4.The cutting speed and capacity

depend on the length of the cutting pipe, the wall thickness and

the feeding speed of the operator. The average cutting time for

skilled workers is only about 0.8 seconds (refer to the stainless

steel round pipe with 0.6mm wall thickness).5.The power consumption

is small, the consumables are much lower than those of similar pipe

processing equipment, and it is convenient to maintain.Detailed

PhotosMore Machine Details Pipe sampleApplied MaterialsCutting

a wide variety of metal plates, tubes, mainly applicable to

stainless steel, carbon steel, manganese steel, galvanized sheet, a

variety of alloy plates, rare metal and other materials

cutting.Application IndustryIndustry of Auto parts, Kitchen

hardware, Electric bicycles, Medical machinery, sports equipment,

Furniture, etcPackaging & ShippingCompany ProfileOur

AdvantagesAfter Sales ServicePre-sale services1.Provide

professional consultation:At any time to provide customers with

information consultation on products, prices, technology, industry

solutions and other aspects, including network, telephone, mail and

other ways of consultation.2.Provide sample service: Use laser beam

for free sample proofing and mail to your location.3.Provide

inspection reception: Customers can make an appointment to visit

the exhibition hall, visit the company on-site inspection, the

company provides professional reception personnel.While-sale

services1.Integrity and fairness: no matter the size of the

contract amount, no matter new and old customers, no matter which

country of customers, we will be honest.2.Quality and quantity

guarantee: we strictly implement the terms of the contract, and we

will strictly comply with the product standards and carry out

multiple quality tests for each equipment ordered by

customers.After-sale services1.Our company could provide

technical support and training for you in your country, if

necessary.2.Our company is responsible for free installation,

software upgrade and lifelong maintenance.3.Our engineer could

serve for you 24 hours online, by Whatsapp, Wechat, QQ, or by

cellphone, etc.4.Professional after-sales service system, for users

uninterrupted processing to provide guarantee, installation guide,

maintenance guide, etc.FAQQ1: How do we guarantee quality?A:It is

always a pre-production sample before mass production, always

perform a final inspection before shipment. provide production,

delivery, samples, etc. videos at all times.Q2: Why should you buy

from us instead of other suppliers?A:All the machines are tested

well before delivery with guaranteed quality and best prices. There

is a 12 months warranty. Different material and the different model

apply to the different machine. Please tell us what's material you

want to cutting or engraving ?And what's MAX size of carved

material ?We will recommend the most suitable model and the best

price for you.Q3: Do you have after-sales support?A:Yes, we are

happy to provide suggestions, and we also have skilled technicians.

If the machine fails during warranty period, just contact us. Our

sales are online for 24-hours and ready to help you(make sure it is

not broken because of wrong op

Related products about Customized Fibre Laser Cutting Machine for Pipes or Tubes

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup