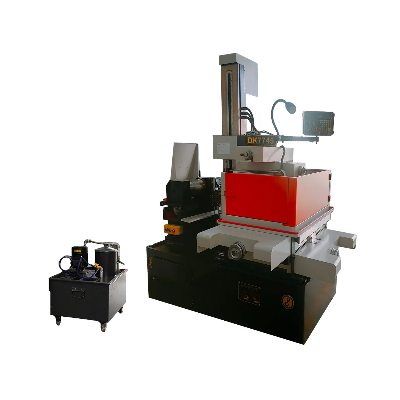

High efficiency

fast wire cutting is a set of machine tool electrical appliances,

high frequency power supply, servo control and graphics programming

as one, to achieve high efficiency, high precision, high finish,

simple processing control, greatly improve the processing level of

fast wire cutting machine. Flexible

commutation with frequency converter is adopted in machine tool

commutation, which can arbitrarily adjust the speed of wire

conveyor drum, thereby improving the smoothness of workpiece. High

efficiency (cutting efficiency can reach 7000 to 8000 square

millimeters per hour) is twice the cutting efficiency of ordinary

machine tools. Energy saving (machine energy consumption is 0.85

degrees per hour) is 50% more energy saving than that of ordinary

machine tools. Environmental protection (machine tool environmental

protection water cover to prevent working fluid splashing) can be

replaced once in 30 working days by using high-pressure filter

water tank working fluid, which greatly improves working time and

reduces the number of sewage discharge. The electrical parts of the

machine tool are all installed in the control cabinet for

waterproof treatment, and all the oil supply is integrated with

manual oil pump.1.Select paired clearance-free bearings to improve

accuracy.2. Selection of high quality ball screw3. Using

steel-inlaid guide rail4. Good assembly process requirements5.By

using frequency converter, the speed of the wire drum can be

adjusted arbitrarily, thus improving the smoothness of the

workpiece.6.Conventional processing efficiency can reach 150

mm2/min. S/NItemParameter1ModelNational

Standard 352Electrical cabinet formStanding cabinet/counter (full

step type)3Guide railSteel-inlaid guide rail4Lead screw formBall

screw5XYUV Motion Motor FormReactive stepping motor6Working mode of

wire-moving motorFrequency Converter Speed Regulation

1~12m/s7Machine ProtectionEnvironmental Protection

Cover8Motion Resolution of Motion Axis0.001mm9Woektable

size850X80010X-Y Axial Travel450X550mm11U, V-axis

travel±35×±35mm12Machining taper/thickness±6°/80mm 13Max. Linear

Cutting Thickness400mm(Z-axis manual lifting)14control mode4-axis

linkage15Max.Load Weight160kg16Max. Processing

Current8A17Max.Machining EfficiencyCr12,H=60mm≥180

mm²/m18Surface roughness(Linear cutting,H≤40mm)Ra≤2.0μm19Cutting

accuracyCr12,H=40mm≤0.01mm20Radial Running of Storage

Cylinder≤0.02mm21Diameter range of molybdenum wire0.12~0.22mm22Silk

storage capacity 250m23Molybdenum Wire LossCr12,H=40mm≤0.02mm

/300000mm²,24Cutting power supplyNon-resistive High Frequency Power

Supply System25operating systemWindows 98/XP(According to Control

Software)26Control systemAUTOCUT/HL/HF27communication

interfaceLAN,RS232,USB28Operational functionDrawing or importing

CAD graphics29Working tank volume55L30Working fluid filtration

modeScreen filtration31Total Weight1200 kg32Outward Size of Main

Engine1650x1250x1700mm33Cabinet size730×630×1220mm34Rated power of

electrical appliances≤ 2kWList of attached accessories

S/NProduct nameSpecificationsFree

delivery1scissors312HexagonalwrenchM4-M10(5)13Stiff

hands14-1714WoodenscrewdriverOne type, cross type25Oil gunMetal

shell16Molybdenumwire calibratorH80mm17Top wire

wheel 18Working fluidWater working fluid, Jiarun

jr3a19Electrode wireRecommended 0.18mmmolybdenum wire500m10Guide

wheelDia.49.5mm211Bearing625ZZ812Conductive block12mm×12mm2Our

Strength:* Over 12 years manufacturing experience in CNC lathe

machine.* The company abides by the concept of "providing

high-quality,stable and cost-effective products and good services

to the clients by relying on advanced and reliable

technology, * Always adheres to a large amount of research and

development investment and continuous engineering improvement*

Longkai EDM machines are with high cutting accuracy, high cutting

speed, high surface finish and high stability. * We have

always been in the leading position of the reciprocating wire

cutting machine, electrical processing power and control

technology.After-sale Services:Warranty is one year.We would offer

the parts (quality problem) free of charge during this period,

freight collect./* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about 2020 High Speed EDM Wire Cutting Machine Automatic Wire Cutting Dk7745

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup