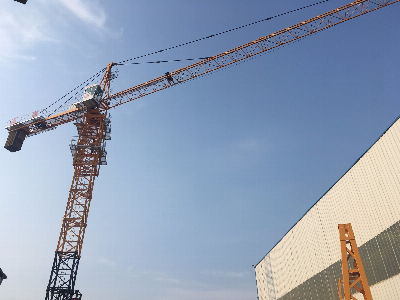

Shandong Baimai Construction Machinery Co.,Ltd found in Year

1995,is the appointed professional manufacturer of tower crane by

the State Bureau of Quality and Technical Supervision.Our company

insist on "technology prosper the factory", depend on the R&D

institute, the universities tech advantage and our own strength,

develop QTZ40,QTZ50,QTZ63,QTZ80,QTZ100,QTZ125,QTZ160,QTP5015 Hammer

Head Tower Crane, PQZT flat-top tower crane and

SC200/200,SCD200/200 building construction hoist . Our company

insist on "guarantee the product by moral character, pay back the

society by the product" and"casting the brand by quality, win the

trust by reputation" ,devote to increase the construction industry

mechanization level,develop the inner climb series tower crane in

2004,the climbing tech is word advanced, award 60 more national

patent. Climbing convenient, safety, high economic benefit, save

much money, enhance the safety performance and the working

efficiency, is the first choice lifting device for the high rise

building. To better pay back the society and support western china

development, we build Sichuan Baimai Construction Machinery Co.,Ltd

in Guang An Sichuan in Year 2010.The company covers over 80 acre,

register capital RMB15,000,000. FAQQ: Which area is your

company's product applications?A: Baimai main products include

tower cranes and construction hoists, widely used in industrial and

civil buildings, to meet the high-rise building, energy

construction, and bridge construction. Usage is divided into

traveling type, fixed type, fixed attachment type, inner climbing

type, and wire rope soft attached type. The maximum lifting

height can be configured according to project requirements.Q: What

is the range of the crane weight and amplitude of your company's

crane and what are the parts?A: We can supply tower cranes

from 4t to 200t, Jib lengths from 6m to 85m, including stationary

type, inner climbing type, and traveling type. Our tower crane has

excellent performance, and competitive prices, and is equipped with

complete safety devices, easy to install and

disassemble. Tower Crane Model is as

follows: 1) Hammerhead Tower

CraneBMT4810-4BMT5011-5BMT5013-5

(MC85)BMT5516-6(MC115B)BMT6014-8(MC175B)BMT5023-10

(F0/23B)BMT6015-10(H25/15)BMT6024-10(MC200)BMT6025-10(MC205B)BMT6520-10(MC230)BMT6036-12(H3/36B)BMT7030-12(K30/30)BMT7032-12(MC310

K12)BMT7032-14(MC310 K14)BMT7027-16(MC310

K16)BMT7050-20/25BMT8030-25(MC475 M25)BMT70110-32BMT70100-502)

Topless Tower

CraneBMP4810-4BMP5010-5BMP5013-8BMP5517-8BMP6520-12BMP7524-16BMP7524-18BMP70240-803)

Luffing Tower

CraneBMD4015-5BMD4522-8BMD5030-10BMD5522-12BMD6037-164) Roof

CraneBMWD1540-4TBMWD1830-4TBMWD1840-5TBMWD2025-6TBMWD2420-8TBMWD3023-10T5)

Inner Climbing Mini Tower CraneTC4810:Load:1.0/4t, Jib:48m,

Height:21m/140mTC5010:Load:1.0/5t, Jib:50m,

Height:21m/140mComponents : 1. Hoisting System2. Climbing

System3. Trolley System4. Slewing System5. Electrical System6.

Crane Jib7. Counter Jib8. Mast Sections9. Tower Head10. Control

CabinQ: How is your company's product packing?A: After the products

have passed acceptance, they shall be packed in accordance with the

relevant packaging technical requirements and the corresponding

national standards. The packaging shall ensure that the equipment

of the contract is kept in good condition during transportation and

storage and has moisture-proof, mildew-proof, and anti-mold Rain,

rust, corrosion, vibration, shock, pollution, and other

measures. Q: How is your product quality?A: Our company have

passed the ISO9001-2008, ISO14001-2004, CE, and SGS

certification.The welding process of the product parts is completed

by the automatic robot assembly line, this system comes with an

adjustable angle, welding with high precision and the appearance of

the weld is beautiful and smooth. The most important thing is that

the welding system has no emotional interference, stable

performance, and high work efficiency. In the product process,

large plates, profiles pretreatment lines, spraying lines, the

steel before welding, shot blasting, and painting process ensure

that the surface quality achieves the highest standards in the

industry.We rely on a strong scientific and technological

team, advanced technology, excellent equipment, and accurate

detection methods, making "BAIMAI" brand product quality all meet

or exceed international standards, in terms of accuracy,

reliability, life expectancy, and other indicators reached the same

product advanced level.Q: How is your company's production

capacity?A: Equipped with the most advanced equipment to create the

highest quality product development strategy, producing Panasonic

automatic robot equipment and high-end domestic configuration

products, the new advanced production equipment has more than 200

units. All CNC machining equipment used, automatic CNC cutting

line; grinding process with more than 70 various types of grinders,

CNC up to 90%; heat treatment has the world's most advanced

hardening connection

Related products about Tc5610 Tower Crane with CE Cetified Best for Group Residential Building

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup