Ω Our FactoryQingdao Merid Machinery Co.,Ltd was established in

Qingdao, China in 1991, with and area of 56,000 square feet. We are

a professional top provider and industrial leader of

full-service stamping, welding, machining, die castings and

fabrication of metal components.The fields covers:1.Automotive

parts2.Medical parts3.Agricultural parts4.Stock farming

parts5.Architectural parts6.Industrial partsMerid is equipped with

the in-house capabilities of taking your project from design

- tooling - prototype - production to finish, and

the professional technical and production team could provide you

the best solutions to ensure high quality and cost effective

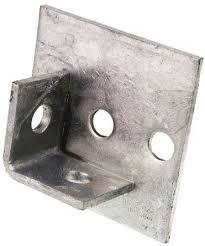

production of your products.Ω Product DescriptionItem nameSheet

Metal Stamping Shelf Angle BracketSurface

Treatmentgalvanized,polishing,Zinc, powder coating, painting,

nickle, chromeMaterialStainless Steel, AluminumPrice TermFOB

QINGDAOTolerance+/-0.01mmOEM ServiceYesDelivery Time20 days based

on the different productsPackageCarton,Wooden Case or as

RequiredIndustryCustomized parts are used in

Building,Automotive,Electrical,Machinerassembly,Furniture,Aoil

field Equipments,Marine

equipments,AgriculturalMachines,Transportation Equipment,OEM/ODM

Electronics.........Ω Inspection:Ω Workshop:Ω SHIPPING WAY:Ω

Packaging:Ω Clients show:Ω FAQ:1.What are our advantages over

others?a). Stamping, Machining, Welding, Die casting and Surface

treatment equipment are equipped for providing you our best service

and solutions.b). On-time delivery.c). Strict Quality Control

System: 100% inspection before the shipment.2.What are the

production capacity of our company?a). In Merid, fabrication works

include precision stamping, deep drawing, fine blanking, cnc

punching, cnc bending, laser cutting, flame cutting, cnc milling,

cnc turning, tube bending, aluminum extruding, welding, die

casting, etc.b). Metal materials include stainless steel, iron,

carbon steel, spring steel, aluminum, titanium, copper, brass,

bronze etc.3.What equipments do we own?a). Punch Press:

16T-500T.b). Welding: Carbon dioxide welding, spot welding, tig

welding, automated robotic welding.c). Machining: CNC lathe and

machine centers, light machines(drilling, milling and tapping).d).

Die casting: 80T-500T.e). Surface treatment: Shot blasting

facility, Polishing, Deburring.4.What finishes can we

provide?The finishes which we could provide is powder coating,

painting, galvanizing, baked enamel, anodizing finish, and other

plating finishes.5.How can we guarantee the quality?Quality control

department build the control plan before starting the project, the

strict inspection will be applied throughout the whole

production./* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Sheet Metal Stamping Shelf Angle Bracket

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup