COMPANY INTRODUCTION Baoding Worth Engineering Technology Co.,

Ltd. founded in 2001 , Company is located in the Chinese

ancient city --- Baoding. Our company has been engaged in producing

custom made engineering accessories, OEM/ODM spare parts and

industrial components for many years, including sand casting parts

and investment casting spare parts, forging parts, sheet metal

stamping spare parts, machined parts and plastic parts, which are

widely used in petrochemical, automobile, chemical, environmental

protection , machinery, construction, agriculture, aerospace,

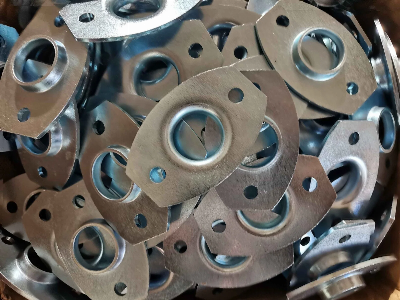

marine hardware and other industries. STAINLESS

STEEL/ALUMINUM/CARBON STEEL/ SHEET METAL STAMPING AND DEEP DRAWING

Stamping (also known as pressing) is the process

of placing flat sheet metal in either blank or coil form into a

stamping press where a tool and die surface forms the metal into a

net shape. Stamping includes a variety of sheet-metal forming

manufacturing processes, such as punching using a machine press or

stamping press, blanking, embossing, bending, flanging, and

coining. This could be a single stage operation where every stroke

of the press produces the desired form on the sheet metal part, or

could occur through a series of stages. The process is usually

carried out on sheet metal, but can also be used on other

materials, such as polystyrene.Deep drawing is a sheet metal

forming process in which a sheet metal blank is radially drawn into

a forming die by the mechanical action of a punch. It is thus a

shape transformation process with material retention. The process

is considered "deep" drawing when the depth of the drawn part

exceeds its diameter. This is achieved by redrawing the part

through a series of dies. The flange region (sheet metal in the die

shoulder area) experiences a radial drawing stress and a tangential

compressive stress due to the material retention property. These

compressive stresses (hoop stresses) result in flange wrinkles

(wrinkles of the first order). Wrinkles can be prevented by using a

blank holder, the function of which is to facilitate controlled

material flow into the die

radius.Company Capabilities:(1).CNC machining parts(2).The fabrication(3).The mechanical assemble(4).The Surface treatment Plating :3+Cr,environmental,anti-corrosion maximum 480 hours salt spray testCoating:powder coating,electrcial coating,maximum 480 hours salt spray testPainting:environmental EXPOSY painting,cross-cutting testPolish:satin polish,mirror polish,electrical polish, maximum 1200 gridDacromet:evironmental,anti-corrosion,maximum 560 hours salt spary testAnodization:tumble,shot blast,sand blast.....,various color,maximum 480 hours salt spray testNylok:tight-locking,environmental,5 million timesHeat Treatment:adjust the mechanical properties,temper,normalization,quench......(5).The Variousl Materialstainless steel:SS304,SS304L,SS316,SS316L,SS430,SS201......aluminium:7075,6061,6063,5082,5051,2014.......brass:H62,H58,H59......steel:C20,C45,C60,C35......steel alloy:25CrMo,42CrMo,25Cr,40Cr,Q345,11SMn30......iron cast:QT600,QT250,HT450,HT150......titanium alloy:GR2,GR5,GR7,GR9......tungsten alloy:WuNiFe alloy,Carbide Wolfram......the blanks:stamping parts,forging parts,die casting parts,profile,extrusion......the plastic:PP,PE,POM,Acrylic,ABS,Delrin......

COMPANY EQUIPMENTSTESTING EQUIPMENTTHE PACKAGE AND

SHIPMENTCUSTOMERS FAQ Q1. How to customize

products? A2:

Attach your drawings with details (material, surface treatment,

quantity and special requirements etc). Q2:

Can you make the parts based on the sample?A3: Yes, we could

provide a rough cost and will measure and design the drawing

according your sample.Q3: Can my design be safe after sending it to

you?A5: We can sign the NDA before you send

it.

Q4.

How long will it take to get the

quotation? A6:

We will give you the quotation within 24 hours (Considering the

time

difference). Q5.

How does the company control the

quality? A7:

Inspection product with professional equipment , like CMM, height

gauge, caliper & micrometer, Ultrasonic fault detector, Hardness

tester, Spectrum analyzer, impact testing machine, quadratic

equipment . /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Sheet Metal Stretch Forming Parts Metalparts Deep Drawing Pressing Stamping Parts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup