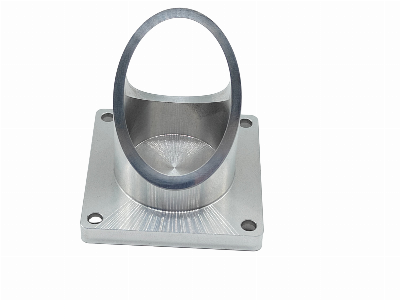

High precision, quick turnaround, low process cost. Our factory

equipped with 5-Axis CNC Machining Centers, Millers and Lathes, we

provide CNC machining services for medical industry, consumer

electronics, aerospace and defense, etc. Get in touch with us to

start a mutual beneficial cooperation. Product

Parameters Basic Info. of Our Customized CNC Machining

PartsQuotationAccording To Your Drawings or Samples. (Size,

Material, Thickness, Processing Content And Required Technology,

etc.)Tolerance +/-0.005 - 0.01mm (Customizable)Surface

RoughnessRa0.2 - Ra3.2 (Customizable)Materials

AvailableCeramic,Tungsten,Aluminum, Copper, Brass, Stainless Steel,

Titanium, Iron, Plastic, Acrylic, PE, PVC, ABS, POM, PTFE

etc.Surface TreatmentPolishing, Surface Chamfering, Hardening and

Tempering, Nickel plating, Chrome plating, zinc plating, Laser

engraving, Sandblasting, Passivating, Clear Anodized, Color

Anodized, Sandblast Anodized, Chemical Film,

Brushing, etc.ProcessingHot/Cold forging, Heat treatment, CNC

Turning, Milling, Drilling and Tapping, Surface Treatment, Laser

Cutting, Stamping, Die Casting, Injection Molding, etc.Testing

EquipmentCoordinate Measuring Machine (CMM) / Vernier Caliper/ /

Automatic Height Gauge /Hardness Tester /Surface Roughness

Teste/Run-out Instrument/Optical Projector, Micrometer/ Salt spray

testing machineDrawing FormatsPowermill CAD Mastercam

creo hypermillOur Advantages1.) 24 hours online service & quickly

quote and delivery.2.) 100% quality inspection (with Quality

Inspection Report) before delivery. All our products are

manufactured under ISO 9001:2015.3.) A strong, professional and

reliable technical team with 25+ years of manufacturing

experience.4.) We have stable supply chain partners, including raw

material suppliers, bearing suppliers, forging plants, surface

treatment plants, etc.5.) We can provide customized assembly

services for those customers who have assembly needs. Common

Materials of Stamping UsedThe choice of metal stamping materials

used depends on the required properties of the final product.

Stamping is not limited to the metal manufacturing process, there

are many other materials that can be processed by stamping

technology, such as paper, leather or rubber. But so far, metal is

the most commonly used material.Some common metals and metal types

manufactured by stamping include:. Precious metals: silver, gold

and platinum. Ferrous metals, especially iron-based alloys like

stainless steel. Non-ferrous metals: bronze, brass and zinc.

Non-standard alloys: beryllium nickel and beryllium copper Our

Material. Stainless steel: SS201, SS301, SS3004, SS316, etc..

Aluminium: AL6061, AL6063, AL7075, ALA380 etc.. Brass: C22000,

C24000, C26000, C35600, etc.. Copper: C10100, C11000, C12000,

C12200, etc.. Plastic: Peek, POM, PP, PC, ABS, Nylon,

etc.Surface Treatment From QiJia PrecisionHeat Treatment, Painting,

Power Coating, Black Oxide, Silver/Gold plating, Electrolytic

Polishing, Nitrided, Phosphating, Nickel/Zinc/Chrome/TiCN Plated,

Anodizing, Polishing, Passivation, Sandblasting, Galvanizing,

Heating Treatment, Harden, Laser mark etc. as customer

requested. Our CapabilityFast communication,

Professional technology, Excellent product quality, Reasonable

Price and Wonderful after-sale service.We provide various CNC

machining service to meet your needs of machined parts and

components, from rapid prototyping to customized precision parts

and end-use products, from aluminium and zinc die casting to deep

drawn stamping and metal fabrication as well. Our

Advantages Increase speed - draw speed is only limited by the

required contact speed of the material. If multiple stretches are

required to produce the finish draw, it can be performed at the

same time at the transfer or progressive die station, thereby

optimizing the cycle time.. Cost effective - along with the

productivity savings, the cost of molds for deep drawing is also

lower, usually only a set of very durable and renewable simple mold

steel or cemented carbide molds, thereby reducing the need for

re-molding.. Maintain tolerances - the deep drawing process is

extremely repeatable and once set up, thousands of parts can be

produced within strict tolerances.. Strong parts - rolled metal has

a slender and cohesive grain structure. Due to the nature of the

deep drawing process, the structure flows uninterrupted in the

deep-drawn part, resulting in a very strong finished product..

Metal diversity - various metals can be deep drawn, providing many

manufacturing options.Our PackingWe have high-quality packaging

cooperation suppliers, We can provide foam, pearl cotton, paper

cases, wooden cases and other packaging. The package is tight, not

easy to bruise, we provide good service Our

Equipment Application. Wide range of aluminium materials:

Aluminium 5052-H32, Aluminium 6061-T651, Aluminium 7075-T651, etc..

Optional surface treatment: Anodizing, Chromate, Powder-coating,

Sand blasting, Polishing, etc.. Custom colors: Natural, R

Related products about High Precision CNC Machining Drilling Stamping for Precision Parts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup