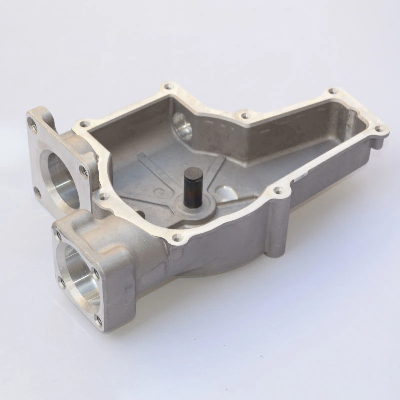

Name: Die Casting For Aluminum Electronic Tool PartsWelcome to send

the drawings for alumium die casting, Zinc casting quotation.

Casting MachineDie casting machine 88 ton, 125 ton, 200 ton, 280

ton, 400ton, 500 ton, 800 ton,1000 tonMaterialAluminum alloy ADC10

ADC12 ADC14 A360 A380, zinc alloyCasting MoldDesign,

Fabrication, Test, Modification & MaintenanceSurface

TreatmentSandblasting, Polishing, Plating, Powder Coating,

Anodisation etcAccuracyClass CT4~CT11Surface

RoughnessRa1.6~Ra6.3Machining Equipment3/4/5 Axis CNC machining

center, CNC engraving machine, CNC milling machineCNC turning

machine, high precision grinding machine, WEDM etcCasting is

broadly defined as the process of forming a substance into a

specific shape using a mold. Metal casting employs a variety of

metals to create the molded end product and dates back thousands of

years.The most commonly materials used resources are: gray iron,

ductile iron, aluminum, steel, cooper, zinc. We have good factories

of investment casting, die casting, sandy casting etc. Things to

Consider When Choosing Casting Materials * Level of volume required

* Cost-effectiveness * Melting temperature * Cooling speed * Wear

resistance * Weight * Damping capabilities Industrial Casting

Applications Casting is used in a large number of manufacturing

process and plays an important role in construction. Many

industries depend heavily on casting to create uniform products.

Some of the leading markets for casting materials are: * Automotive

and Light Truck * Pipe and Fittings * Construction, Mining and

Oilfield Machinery * Internal Combustion Engines * Railroad *

Valves * Farm Equipment * Municipal Castings /* March 10,

2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Die Casting for Aluminum Electronic Tool Parts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup