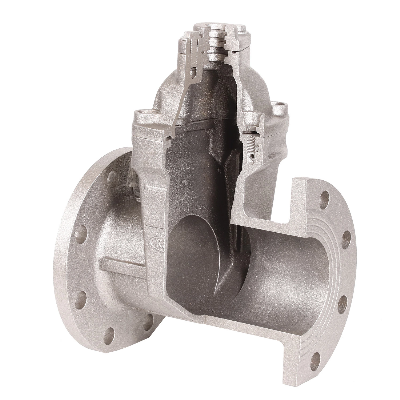

OEM Stainless Steelcastings, lost wax production craft, machining

choice will be according to the actual tolerance request and demand

quantity. Most of Our produced castings are used for valves,

hydrants, pumps,trucks,railway and train and so on. Manufacturing

technique:Lost Wax Precision Casting Material: SS316, SS304, 1.4310

Product weight:0.2Kg-200Kg MaterialAluminum: AL6061, Al6063,

AL6082, AL7075, AL5052, AL2024Stainless steel: SS201, SS301, SS303,

SS304, SS316, SS430 etcSteel: mild steel/ carbon steel including

1010, 1020, 1045, 1050, Q690 etcBrass: HPb63, HPb62, HPb61, HPb59,

H59, H68, H80, H90 etc.Copper: C11000, C12000, C12000, C17200,

C72900, C36000 etc.Processing EquipmentGermany Trumpf brand

Laser cutter, CNC shearing machine, CNC bending machine,(CNC)

stamping machine, Hyraulic Machine, Various welding machine,

CNC machine center.Surface TreatmentAluminum:

Anodization, Sandblast, Brushing, Polishing, Electro-plating

etcStainless Steel: Polishing, Brushing, Passivating, Sandblasting,

Electro-platingSteel: Zinc plating, Nickel plating, Chrome plating,

Powder Coating, Painting etcBrass & Copper: Brushing,

Polishing etcPrecision+ - 0.1mmApplicationRailway, Auto,

Truck, Medical, Machinery, Equipment, Electronic, Electrical

etc Product ParametersBasic Info.Product Name OEM Sand

Casting Parts Gate Valve Body Parts of Ductile Iron

/Copper/Aluminum /Brass / Iron /Zinc/Carbon Steel/Stainless Lost

Wax Investment Die CastingMaterial Ductile Iron

/Copper/Aluminum /Brass / Iron /Zinc/Carbon

Steel/Stainless Surface Preparation Sand Blast,

Polishing Machining Tolerance According to your

request Certification ISO

9001:2015 Technology Investment Casting, Die Casting,

Gravity Casting Surface Sand Blasting,

Polishing Casting Tolerance Investment castingCT4-CT6,

casting CT9-CT10 Inspection 100% Visual

Inspection Lead Time 30

Days Package Cartons+Wooden

Case/Pallet Specification OEMOrigin ChinaHS

Code 8481901000 Production

Capacity 100tons/Month Application Machinery

Parts Detailed PhotosOur Advantages Mingda offers

precision turning services from the latest CNC turning machines .

With more than 10 years' experience in custom precision machining

services, we are committed to provide high quality products with

competitive prices. We can provide CNC precision machining parts,

CNC turning parts, CNC milling parts, surface grinding, CNC

engraving etc. Parts can be produced from 1mm to 300mm in aluminum,

alloy steel, stainless steel, brass and plastic (nylon, PMMA,

teflon etc.). And we can also do the secondary processing and

sub-assembly work for you when CNC prototyping or production is

completed. More than 10 years' experience of designing and

producing all kinds of precision machining parts. CNC Precision

Machining Metal parts for customers overseas and domestically.

Specialized in manufacturing products and components with tight

tolerances and complicated shapes. OEM Ductile iron sand castings,

lost foam casting, Vacum Moulding and so on,the moulding craft will

be slected according to the actual tolerance request and demand

quantity. Most of Our produced castings are used for valves,

hydrants, pumps,trucks,railway and train and so on. company

introduction:Hebei Mingda International Trading Company is a

trading company which is specialized in castings,forgings and

machinery parts. Our products include all kinds of raw castings to

be made of ductile iron , grey iron , brass , stainlesssteel and

aluminums, machined castings and forged parts . To make these parts

according to thecustomers' drawings , we have relative suitable

production craft and equipments, such as resin sand ,sand mould ,

hot core boxes , lost-wax , lost foam and so on . Specially for

hydrant bodies and valves' bodies, we have collected rich

experience for these products inthe past 16 year's actual

production, Now we are proud of our products with good surface and

highquality material. Whatever,we have been trying our best to

provide our customers with better quality castings by improving

production crafts and more careful quality control. Looking Forward

To Receiving Your Kind Favorable Reply At Your Earliest! Packaging

& Shipping /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about OEM Customized Gate Valve Body Parts of Ductile Iron /Copper/Aluminum /Brass / Iron /Zinc/Carbon Steel/Stainless

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup