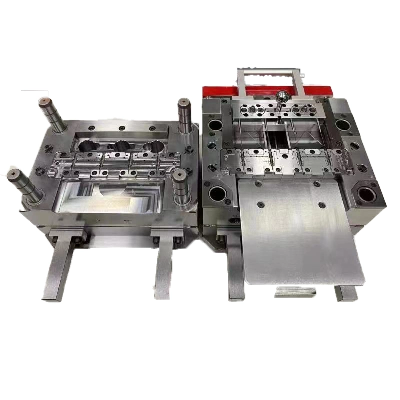

High Precision OEM Plastic Injection Parts Molding Plastic Moulding

Injection Mould Stamping Die Supplier with Rapid ToolingWhy Choose

Us:1. Founded in 2008, Cover an area of 10000 sqms Plant; Provide

OEM/ODM Service2. Certified by ISO90001, SGS,CE,UL etc3. Over 15

years experience in Mold Making & Plastic Injection Parts Mass

Production4. Integrating R&D, QC System & Marketing Sales.5.

One-stop Service of Custom mold design from Initial drawing design,

Material selection assistance, Mold structure/Mold flow analysis,

Trial & mass production to Final mold assembly &

shipment. Plastic Injection MoldProduct Material ABS, PP,

PC, PA66+30GF, PVC, POM, TPE, TPV, ASAMaterial of

Steel1040/1050,P20,P20HH, H13,420 etcSurface RequirementSmooth,

Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser

Etching, Anodizing,BrushingTolerance Request UP

to (±0.005mm)Mould Life500000-1200000 shootsMulti

InjectionSingle/Double/multi colorDesign SoftwareAuto CAD,DXF,

DWG,STEP, STP, IGES, X_T,STEP, STP, IGES, X_T POWERMILLInjection

SystemHot /Cold RunnerInserts(cavity and core) H13, 1.2344,

1.2738, 1.2083, 1.2311, NAK80 or the material you requiredMold

Cavity 1*1,1+1,1*2,1+1+1,etc Gate typeSide gate,Sub

gate,Pin point gate,Edge gate etcEjector SystemStripper

plate,Lifter,Push bar,Ejection pin etc Steel

StandardFINKL,Assab,DAIDO,LKM,Buderus CoolingBaffles/Sprin

Piple/3D printing water lineStandard

Parts/CylindersDME/HASCO/PROGRESSIVE/MISUMI/Parker/HP/MerkleDesign

CapabilityDFM,Mould flow analysis,Product optimization, Full 2D &

3D mould design,Reverse engineering,Collaborative design with

customer's ideaDocuments / Reports ProvidedFully drawing,Weekly

Processing Report, Steel Dimension report, Processing Report,Sample

Dimension ReportCertificateISO9001 ISO14001 MOQ1setsLead

Time6-10 weeks or according to the order

requirementPayment40%Deposit, 30%Before Product Inspection,

30%Before ShipmentPort of loadingSHENZHEN Plastic Materials

Applies: Material NameFeaturesApplicationsPPLightweight, Heat

Resistance, High Chemical Resistance, Scratch Resistance, Natural

Waxy Appearance, Tough and Stiff, Low CostAutomobile (Bumpers,

Covers, Trim), Bottles, Caps, Crates, Handles, Housings.POMStrong,

Rigid, Excellent Fatigue Resistance, Excellent Creep Resistance,

Chemical Resistance, Moisture Resistance, Naturally Opaque White,

Low/Medium CostBearings, Cams, Gears, Handles, Plumbing Components,

Rollers, Rotors, Slide Guides, ValvesPCVery Tough, Temperature

Resistance, Dimensional Stability, Transparent, High CostAutomobile

(Panels, Lenses, Consoles), Bottles, Containers, Housings, Light

Covers, Reflectors, Safety Helmets and ShieldsPSTough, Very High

Chemical Resistance, Clear, Very High CostValvesABSStrong,

Flexible, Low Mold Shrinkage (Tight Tolerance), Chemical

Resistance, Applicable for Electroplating, Naturally Opaque,

Low/Medium CostAutomobile (Consoles, Panels, Trim, Vents), Boxes,

Gauges, Housings, Inhalers, ToysPA6High Strength, Fatigue

Resistance, Chemical Resistance, Low Creep, Low Friction, Almost

Opaque/White, Medium/High CostBearings, Bushings, Gears, Rollers,

WheelsPA6/6High Strength, Fatigue Resistance, Chemical Resistance,

Low Creep, Low Friction, Almost Opaque/White, Medium/High

CostHandles, Levers, Small Housings, Zip TiesPBT,PETRigid, Heat

Resistance, Chemical Resistance, Medium/High CostAutomobile

(Filters, Handles, Pumps), Bearings, Cams, Electrical Components

(Connectors, Sensors), Gears, Housings, Rollers, Switches,

ValvesPVCTough, Flexible, Flame Resistance, Transparent or Opaque,

Low CostElectrical Insulation, Household wares, Medical Tubing,

Shoe Soles, ToysHDPETough and Stiff, Excellent Chemical Resistance,

Natural Waxy Appearance, Low CostChair Seats, Housings, Covers,

ContainersPMMARigid, Brittle, Scratch Resistance, Transparent,

Optical Clarity, Low/Medium CostDisplay Stands, Knobs, Lenses,

Light Housings, Panels, Reflectors, Signs, Shelves, TraysPlastic

Injection Equipment List: EquipmentQTYOriginInjection

Machine15 SETS ChinaCNC Machine Center12 SETSChinaEDM12

SETSChinaEDM Mirror1 SETSJapanWire Cutting8 SETSTaiwanGrinding

Machine3 SETSChinaMilling Machine7 SETSChinaDrilling Machine8

SETSChina Company Advantage: 1. ISO 9001: 2008

certified2. Advanced equipment and excellent R& D

Team3. Highly skilled manufacturing process4. A broad

variety of ODM& OEM product range5. Strict quality Control

System6. Software for specification drawings: STEP, STP, IGES,

X_T POWERMILLHigh quality and fair price is highly strictly

controlled here.Scanning & 3D drawingcan make a 3D drawing through

scanning machine with sampleCNC Machining prototypeABS, PC, Nylon,

good strength, same material features as injection partsSLA & 3D

print prototypecost effective for part show or design testVacuun

casting mold/Silicon moldfor TPU or rubber material, color part

availablePlastic injection mouldsoft tooling or production mould,

can do switch runner at single tool to save tooling

investmentInjection moulding partsABS, PC, POM, TPU

Related products about High Precision OEM Plastic Injection Parts Molding Plastic Moulding Injection Mould Stamping Die Supplier with Rapid Tooling

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup