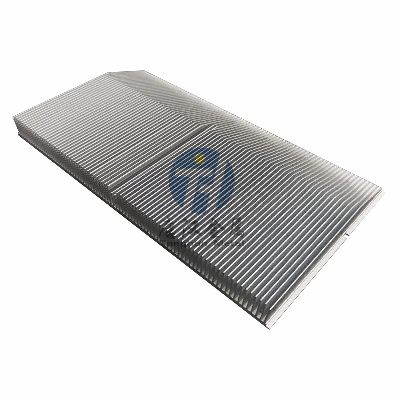

OEM Cold Roll Steel Laser Cutting Bending Welding Fabrication of

Sheet Metal Inspection Equipment Shell Enclosure Case Cabinet

Product Description Metal sheet fabricated

products are widely used in machine shell ,enquipment

components,construction ,automobile etc ,our factory has researched

and focused on this industrial more than 15 years .

At present , Tanghan Metal has 13000m2

square footage of professional workshop and social office with 105

staffs, including 55 skilled workshop workers, 20 engineers for

R&D team , 9 experienced QC ,and 21 professional management

team members etc, After many years of practice, we had imported

various advanced equipment like Trumpf Trumatic 6000L FMC from

Germany, Amada 2510 CNC punching machine and bending machine from

Japan, 6000W laser cutting machine and other producing and

inspection equipment. We can provide

customized services and technical support, different dimensions and

materials(aluminum, mild steel, stainless steel ,etc) are

available, welcome to contact us to get a quote. Product

NameCustom Metal PartsMaterialQ235B ,Q350

,SPCC,SGCC,SUS201,SUS304,SUS316,Alu1100/3003/5052/6061,A380,A413,A360,Adc12,A325,ZL102 etc.Thickness0.5-20mmProcess

Name1Incoming material inspection8Cleaning2Material9Appearance

inspection3Melting10Leakage testing4Die casting11Inspection parts

after chromating5Deburring12Packaging6Process

inspection13Inspecting for

delivery7Machining14DeliveryDrawingProvide by customer, or design

according as the sampleDrwing formatPro/E, AutoCAD, SOLIDWORK,

CAXA, UG, CAD, CAM, CAE, STP, IGES, etc.MouldDesign and produce by

ourselfSurfacepowder coated,polish,mirror,anodizing,zinc plate ,hot

dip galvanized,Drawing time3 daysSample time7-10 daysLead time30

days Detailed Photos 1 .All raw material will be

inspected strictly2.Flat alloy,checker plate,Aluminum profile,Steel

pipe and steel plate,galvanized iron,stailess steel ,aluminum

magnesium zinc plate etcThere are a variety of surface treatment

for choice, spraying, zinc plate, hot dip galvanized, 8K

mirror,anodizing etc,and we make salt spary test regularly to

guarantee the surface treatment qualityThere are different process

products,punching,CNC bending,sheet metal fabrication,stamping,RHS

fabrication ,steel structure ,TIG/MIG,Carbon Dioxide Arg

Welding1.Rich experience in engineering and manufacturing can help

us offer more choice for customers2.There are different

surface,techniques and Custom sheet metal products.Press

riveting,Stud weldingOur factory imported japanese metal fabricated

peers advanced quality management system ,each process like raw

material ,bending ,welding have strict inspection 1.After the

order is confirmed, the engineer will issue the drawing within 1-3

days, which can be customized according to the customer's

requirements2.OEM and ODM are welcomed3.Fixture can ensure the

precision of product bending and weldingCustomized sheet metal

parts, poly wooden box packaging, carton packaging,

custome packagage plan is more stable, to protect the

product does not deformation Hot-sale Products

Welding

TIG/MIG

Outdoor Steel Stairs

Solar Power Light

Battery

Stainless Steel Railing

Testing

Equipment Shell Case

Aluminum profile

Planters Outdoor Pots

Car Accessories

3D Printer

Shell Scanner Main Case Custom Steel Metal Stamping

Parts

Aluminium Dome House

Metal Ventilation Channel

Packaging &

Shipping Our Advantages 1-Factory

ManagementAdvanced Imported Equipment And Factory Management

Stystem Can Guarantee Our Factory Work Effeciently.2-Quality Safety

ReliabilityOur Factory Learned Quality Controling Management System

From Japanese Superior Peers.3-Excellent TeamExperienced Workers,

Professional Engineers, And Hosptial Sales Man will Offer Best

Service For Each Customer.4-Export ExperienceMore Than 15 Years

Exporting Experience,More and Richer Service Will Be Offered To

Clients.About UsFoshan TangHan Precision Metal Products Co., Ltd

was established in 2008,Located in Foshan , Guangdong province .As

a comprehensive metal sheet fabrication manufacturer,we researched

and developed lots of custom metal products , like metal toolboxes,

Ute canopies , dog boxes , valet parking

podiums,bumper,roll bars ,engine skid plate, tonneau cover, metal

wall cladding panel etc ,mainly used in tools storage

,pickup exterior modification,special purpose vehicle

fittings and construction industrial . After these years

of development, we had imported various advanced

equipment from Japan and Germany ,like laser cutting ,CNC

punching/bending /machining,welding robot ,gantry milling etc.we

also

Related products about Wholesale OEM Custom CNC Bending Accessories Galvanized Iron Sheet Precision Metal Bracket/Chassis/Hardware Parts

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup