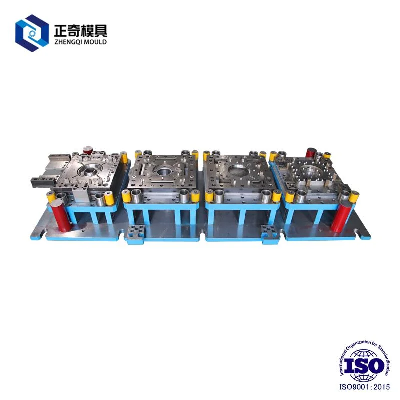

Professional Custom Metal Stamping Die Manufacturer of Progressive

Die and Single-Process Stamping

Die/Mold/Mould/Tooling/Tools.Product Description20 Years of

industrial experience, professional China manufacturer of Stamping

Die and Sheet Metal Processing /Stamping with one-stop

sevice. We are mainly focus on the services of Home

Appliance, Automobiles, Motorcycles and other industrial customers,

from mold design, processing, assembly and debugging, to the

stamping automation equipment matching manufacturing full

process. Brand NameOEMProduct NameMetal Stamping

Die/MouldTolerance± 0.1mm - 5

mmMaterialCR12MOV,SKH-9,SKD11,DC53,45#Design Software2/3D, Auto

CAD, Cae, PRO-E, Solidworks, UgStandardISO9001Mould

TypeProgressive/Continuous Die, Single Process Stamping Die ,

Compound Stamping Die or according to customer requirements.First

Trial25-45 days after mold drawing confirmed.Mould LifeDeepends on

customer's production capactity.Quality ConfirmCan provide strip

layout of die, testing video, inspection certificate and sample of

product.PackageWooden Case for Die/Mould or as customer's

requirements.Company ProfileGuangdong Zhengqi Precision Moluld

company is located in Beijiao Town, Shunde District, Foshan City,

which is the hometown of Home appliance of China.We founded in

2009, takes an area of more than 7, 000 square meters, has more

than 200 employees and 50 technical personnel, annual output value

exceeds 12 million US dollars. We have CNC machine center, CNC wire

cutting machine center, quality testing equipment and others. Our

main business is mould manufacturing, metal stamping and related

automation equipment. We mainly focus on the services of home

appliances, automobiles, motorcycles and other industry customers,

from mould design, processing, assembly and debugging, to the

stamping automation equipment matching manufacturing full

process.We have been deep engaged in the home appliance industry

for more than ten years, have rich capability and experience in

sheet metal manufacturing, research and development, product

sales. Our product materials mainly involve No. 304 stainless

steel and No. 430 stainless iron, SPCC, SGCC, a variety of PCM

color coated steel plate and imported black steel. We can provide a

full set of stamping die production to sheet metal part processing

one-stop service.We are looking forward to have cooperation with

you!Strategic PartnerIn the long-term cooperation with world-class

enterprises, Zhengqi has accumulated rich experience and gathered a

group of professional designers and engineers. We are confident of

provididng quality services and products for all production

enterprises.Our AdvantagesWe have CNC machine center, CNC wire

cutting machine, quality testing equipment and others. Mainly focus

on metal stamping mold and its automation equipment, started from

mold design, processing and assembly, debugging, manufacture to the

stamping automation equipment's full process. Also we have

deeply technical reserves which can effectively solve the industry

difficulties and provide the One-stop Service for customer.We have

20 years mould design experience, mainly focus on the services of

home appliance, automobiles, motorcycles and other industrial

customers. We have sheet metal finite element analysis, 2D &

3D design ability, as well as can do 25 days to 45 days fast mould

delivery, annual manufacturing capacity is more than 600

sets.Precision measuring instrument combined with advanced quality

management system is most important guarantee for the production of

high quality mould. We have Trilinear Coordinates Measuring

Instrument, Metal Material Spectrometer, Rockwell Hardness Tester

and other high quality precision equipments.We have 80T to 800T

punching machines, product Minimum size 0.1mm to Maximum size 5mm

processing capacity, stamping capacty up to 2,000,000 shots per

month. Specific to home appliances stainless steel, PCM

recoated plate and other parts with high surface requirements. We

have deep technical reserves which can effectively solve the

industry pain points.Large Laser Cutting MachineWe have large laser

cutting machine with a table size of 3m x 1.2m. For large order

quantity but limited capacity demand of sheet metal parts, we can

provide the service of fast production and delivery without opening

mold.Technologylaser cutting, metal stamping, sheet metal forming,

turning, wire EDM, weldingSurface TreatmentPlating, Nirtriding, TD,

PVDOEM ServiceAccording to customer's product features and

production capacity, we can provide various products and services,

such as progressive die, multiple machines and stations connecting

rod line, in-mold multi-station manipulator, we have ability to

provide customer with a full set of stamping, processing one-stop

solutions.Certifications Packaging & ShippingFAQ1. Are you a

manufacturer or trading company?A: We are a manufacture with 20

years mold design experience and manufacturing capability in the

field of metal stamping and

Related products about China Manufacture of Quality Metal Sheet Progressive Stamping Mold Punching Die

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup