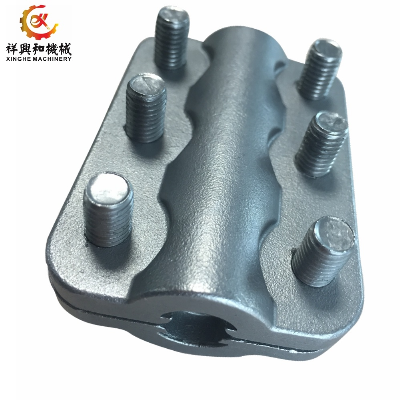

OEM stainless steel precision casting for machinery parts with

polishing 1. Details.MaterialSteel,Stainless Steel,Carbon

SteelTechnologyPrecision casting,lost wax, water

glassPart WeightFrom 3 g --- 20kgsSurface

treatmentSand blast,polishing,painting,powder

coatingCasting Machine 200-1200 tons Capability Output 100 tons per month.New Moulds Opening new mould about 30 days .Fabrication

Investment designing→investment

making→Smelting&alloying→QC→investment

casting→remove burrs→QC→Surface treatment→QC→Packing→QC→Shipping→After Sale ServiceDeep Processing CNC / Cutting / Punching / Checking / Tapping / Drilling / MillingCertification 1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC.MOQAs customer's.Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ.Payment T/T: 50% deposite, the balance will be paid before delivery;Delivery time

1.Mould: 30-35 days 2.Bulk

Order: 30-40

daysOEM Available.2.Investment casting

technology3.Surface treatment4.Inspection processIn order to ensure

the quality of the orders, our

independent QC members to carry out strict

inspection at each stage: (1) Inspection

in-house and third party (2) All the products are

strictly inspected by operator and skilled QC with record put

down. (3) Universal inspection tools: hardness tester,

height ruler etc.5.Package6.About usQingdao Xinghe Machinery Co.,

Ltd. Jointly manufactures and exports a variety of casting products

for architectural, automotive, mechanical parts. We export to more

than 20 countries on 6 continents and have been doing so for more

than 10 years.Our main product line includes sand casting,

precision casting, die casting, forging, stamping, welding and CNC

machining. Materials vary from grey iron, ductile iron, bronze,

aluminum, steel, stainless steel, and so on.We have a strong and

highly efficient R&D team which can design and make OEM/ODM

products according to your ideas and samples.Moreover, in order to

ensure the quality of the orders, our independent QC members to

carry out strict inspection at each stage:(1) Incoming material

inspection(2) Inspection of work-in-progress(3) Finished product

inspection(4) Random warehouse inspectionsAll of our operations are

strictly compliant with ISO 9001: 2008 guidelinesWe own automated

casting lines, CNC machining, CMM inspection, spectrometers and MT

testing equipment, X-ray.To benefit from our strong OEM/ODM

capabilities and considerate services, contact us today. We will

sincerely create and share success with all clients./* March 10,

2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about OEM Custom Casting Stainless Steel Precision Casting Brass Lost Wax Casting Clamp

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup