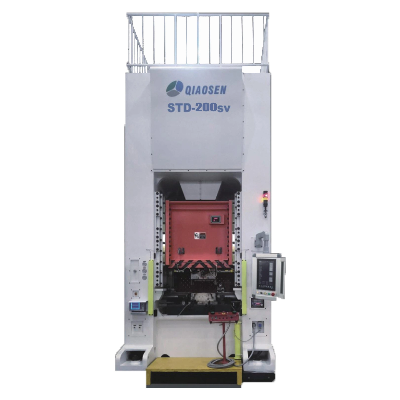

Standard Confirguration >Hydraulic overload

protection device>Air blowing device>Servo motor(Adjustable

speed)>Independent control cabinet>Digital die height

indicator>Mis-delivery detection device reserved

interface>Slider and mold balance device>Photoelectric safety

protection device>Electronic cam switch device>Oil-gathering

silencer>Prejudging counter>Electric grease lubrication

device>Air source connector>Touch (pre-break, prejudge, total

count)>Second falling protection device>Air cooled

chiller Optional Configuration >Pneumatic mold pad

device>Feeder (air, mechanical and NC)>Thin oil lubrication

device>Leveling machine>Quick die change

device (Die

lifter, die clamper or die mover)>Rack>Upper part hit

material device of slider>ManipulatorProduct ParametersPress

capacityImpulse positionSlider strokes per minute(S.P.M)Max mold

heightSlider adjustment amount TonmmSwing mode/mmFull

stroke/mmmmmm2005~100~60450150Slide AreaBolster AreaSide

openingServo motor torqueAir pressurePress accuracy

grademmmmmmNmkg*cm²Grade750*700900*800700*500120006JIS 1 Our

AdvantagesHigh strength steel frameswith small deformationSlide

rail adopt high frequency quenching technology,its hardness could

reach HRC45 degree or more.Advantage: perfect wear

resistanceThe gear shaft is made of high-strength alloy,all tooth

surfaces are treated with medium frequencyAdvantage: small

wear, high accuracy,long service lifeCrankshaftAlloy 42 CrMo

MaterialAdvantage: 1.3 times Stronger than 45 steelBall

SeatJapanese grade TM-3 sintered copper alloyAdvantage: less

failure rate with sawtooth ball Main performance

characteristics :9 processing modes are built-in, and each product

can select the processing curve most suitable for component

processing,So as to achieve high precision, high efficiency and

high energy conservation.Compared with traditional presses, it has

simple structure, high mechanical transmission efficiency and low

maintenance cost. According to the characteristics of

products/materials, the stamping forming speed can be reduced

during the material processing to achieve the best forming speed of

products/materials. Thus reducing vibration and stamping noise;

Improve product accuracy and extend the service life of the

mold.According to different products, different heights are

required. The stroke of the punch can be set arbitrarily, which

greatly shortens the stamping time and improves the

efficiency.Packaging & ShippingAfter Sales Service >

Training:Qiaosen provide complete training for our aboard customers

through Internet so that operators, supervisors and maintenance

team could know well of operation and maintenance as well as simply

trouble shootings.> Maintenance:Qiaosen in-house maintenance

department are responsible for internet inspection and suggestion

immediately. If the remote guidance couldn't solve the

issue, we will arrange the professional engineers to the door for

maintenance by paid service./* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Factory Single Crank Servo Punching Machine Power Press Machine Mechanic Press Stamping Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup