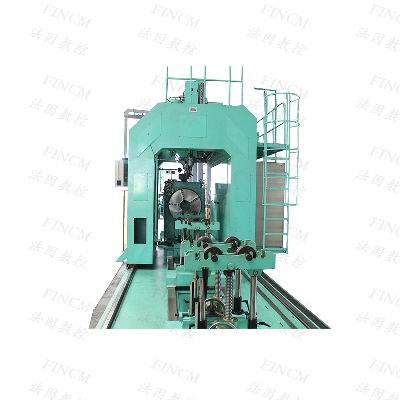

TD1024/3 FINCM CNC Boiler Header Pipe Power Station

High-Speed Drilling Machine Product DescriptionThe

machine tool consists of a base, a gantry, a large slide plate, a

three-axis drilling head, a numerical control indexing head, an

automatic detection device, a pressing device, a follow-up support,

a fixed support, end support, end clamping, chip removal and

cooling system, It is composed of automatic lubrication, hydraulic

system, pneumatic system and electrical system.Main Technical

Specifications:Dimension and machining accuracy of header

pipeProcessing materialsCarbon steel, SA-335P91, etcOuter diameter

of processing headerφ190-φ1020mmBorehole diameterφ20-φ60mmMaximum

diameter of counterboreφ120mmMaximum rotation diameter of

workpieceφ1200mmMaximum drilling wall thickness160mmMaximum length

of processing header24mMinimum hole end distance200mmMaximum weight

of workpiece30tSurface roughness of drilling≤12.5μmDimensional

accuracy of drillingIT8-IT9Center distance deviation of

longitudinal adjacent pipe holes±0.2mmCenter distance deviation of

circumferential adjacent pipe holes±0.5mmDeviation of center

distance between two longitudinal pipe holes±1/1000mm;±2/20000mmCNC

dividing headQuantity1Slewing speed0-4r/min(CNC)Indexing accuracy±

2.5 '(± 0.35mm on the circumference of φ 1000)Diameter of electric

self centering chuckφ1000mmVertical travel±100mmVertical feed rate

modeInchingDrilling head and its vertical slideDrilling spindle

taper holeBT50Number of working heads3Spindle servo motor

power37KwMaximum torque of spindle800NmSpindle speed100-4000

rpm,2500 rpm for continuous and stable operationMaximum axial

moving speed of drilling head5000mm/minLateral movement speed of

drilling head1000mm/minSpindle ram stroke400mmDistance between

spindle end face and axis a300~1000mm(plus skateboard travel)Shaft

spacing of 1,3 drilling head1400mm-1600mm(CNC adjustable)Big

skateboard trip300mmMoving driving mode of large skateboardMotor

and screwGantry (x-axis)Number of gantry1Gantry drive modeDual

driveMaximum stroke of x-axis26mMaximum moving speed of

x-axis4000mm/minotherNumber of CNC systems1setNumber of NC

axes9+3(9 feed shafts, 3 spindles)Testing organization3setsPress

cylinder3 setsFixed support1setFollow up lower support1setEnd

support1setWork Environment:1).Power supply: 3 phase 4

lines 380±10%V

50±1HZ2).Compressed air

pressure:

≥0.5MPa3).Temperature:

0-40°C4).Humidity:

≤75% Company Profile Shandong FIN CNC MACHINE CO., LTD.

is always focusing on our ultimate goal - to secure and increase

our customer's productivity - has made us the leader in China

market in the manufacture of machines for processing angle bar,

beam channel profiles, steel plates, tubesheet and flanges, mainly

serving for fabricating iron towers, steel structure, heat

exchangers, boilers, bridges, and trucks.Strong R & D center with

30 engineers team, 24 years of experience from year 1997, 280

staff, plant area about 270,000 sqm., very harsh quality control of

every component and the whole machine, about 40 million US dollars

sales turnover per year. FIN CNC machines' market share in China is

around 70% and exported to 50+ countries across globe market. All

top ranked tower manufacturers, steel structure fabricators and

power station makers, bridge/railway manufacturers, truck makers

are our clients.Main products: CNC Angle Line, CNC Beam Drilling

Sawing Machine, CNC Plate Drilling Machine, CNC Rail Processing

Machine, CNC Tubesheet Flange Drilling Machine, Truck beam plate

punching machine, etc..One measure of the outstanding quality of

our machines is their longevity: many FIN machines have been in

operation for more than 17 years! Many clients are continually

placing repeated orders which verified well our machines' perfect

quality and reliable performance.The company drafted many China

national standards for CNC angle line machine and CNC beam drilling

sawing machine and CNC plate drilling machine.Cooperative

Supplier Product Process Control Customer

Praise: Sale Networks Customer praise:FAQ:1. When can you

arrange shipment?For machines available in stock, the shipment can

be arranged within 15 days after getting advance payment or L/C;For

machines non available in stock, the shipment can be arranged with

60 days after getting advance payment or L/C.2. What can you do if

my machines have problems?1) We can send you free components if

machines are in warranty period;2) 24 hours service on line;3) We

can assign our engineers to serve you if you want.3. Do you provide

machine operation training?Yes. We can send professional engineers

to the working site for machine's installation, commissioning and

operation training.4. Which machine model shall I choose when I

purchase from you?Please share us your material size and your

processing request, then we will recommend our machine most

suitable and most cost effective for your work demand.5. What's

your machine's market share in China?Our market

Related products about TD1024/3 FINCM Factory Supply Attractive Price CNC Rig Drilling Machine For Header Tube

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup