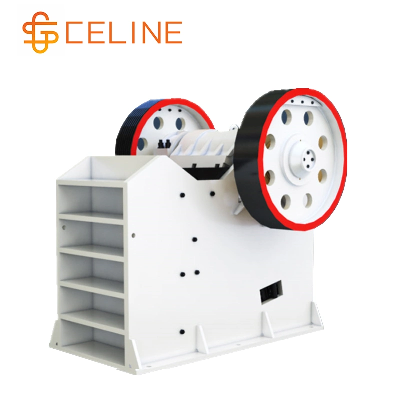

Jaw CrusherProduct DescriptionApplicationJaw crusher is an early

crushing equipment, because of its simple structure, sturdiness,

reliable operation, easy maintenance and repair, and relatively low

production and construction costs. Therefore, it is still widely

used in metallurgy, chemical industry, building materials, electric

power, In industrial sectors such as transportation, it is used for

coarse, medium and fine crushing of various ores and rocks with a

compressive strength of 147-245MPa. In recent years, our factory

has specially developed a jaw crusher to meet the needs of

metallurgy, mining, construction and other industrial sectors to

crush high-strength, high-hardness micro-carbon

ferrochromium.Applicable materials: river pebble, granite, basalt,

iron ore, limestone, quartz stone, diabase, construction waste,

etc.Working PrincipleThe material enters the crushing cavity of the

jaw crusher, and is stacked on the special intermediate bracket in

the machine. The hammer head runs in the gap of the intermediate

bracket, and the material is continuously broken and falling. The

operating hammer is further struck and broken into pieces, and is

discharged after the arc-shaped grate plates are integrated into

the grid. The motor drives the belt and pulley, and moves the

movable jaw up and down through the eccentric shaft. When the

movable jaw rises, the angle between the toggle plate and the

movable jaw becomes larger, thereby pushing the movable jaw to

approach the fixed jaw, and at the same time the material is

crushed or split. crushing to achieve the purpose of crushing; when

the movable jaw goes down, the angle between the toggle plate and

the movable jaw becomes smaller, the movable jaw plate leaves the

fixed jaw plate under the action of the pull rod and the spring,

and the crushed material is discharged from the lower opening of

the crushing cavity .Main Features1. Equipment Energy SavingThe

cavity type of the jaw crusher is in the form of a deep cavity

hyperboloid. The structure of negative support, zero suspension,

small eccentricity and high swing frequency matches the deep cavity

type, making it excellent in high processing capacity, low wear and

low energy consumption. Performance, single machine energy saving

15% to 30%, system energy saving more than doubled.2. Crushing

Ratio is LargeThe jaw crusher has a very high crushing ratio, the

so-called size takes all, the effective power design enables the

material to be crushed multiple times, adopts advanced crushing

technology, and uses advanced digital processing equipment to make

the internal structure precise and improve the crushing

performance. The particle size of the product is uniform.3. High

ProductivityReasonable crushing cavity design, good motion

parameters, determined meshing angle and stroke characteristic

value provide larger crushing stroke, higher productivity and

larger bearing capacity. Yield can be increased by 30%-50%.4. Long

Service LifeThe adopted manufacturing process, the use of advanced

digital components, and the selection of high-end production

materials ensure the precision of machine components, greatly

enhance its compression resistance and wear resistance, reduce

maintenance costs, and greatly extend service life.5. Manufacturing

AdvancedThe parts are made of high-quality materials, which

enhances the compression resistance and wear resistance of the

parts. The movable jaw is made of cast steel, and the eccentric

shaft is processed with forging billets, which increases the

reliability of the parts, high efficiency and durability.6. Wide

ApplicationThe discharge port has a large adjustment range,

reasonable structure and small footprint, which can meet various

processing needs of users and is widely used in crushing production

in many industries.Product ParametersModelInlet

Size(mm)Max.Inlet granularity(mm)Outlet

AdjustRange(mm)WorkingCapacity(t/h)RotationSpeed(r/min)Motor(kw)DimensionL*W*H(mm)PE

150*250150*25012510-401-32684P 5.5760*700*860PE

200*300200*30018015-502-62604P 7.5915*780*990PE

200*350200*35018018-603-102764P 111000*914*1112PE

250*400250*40021020-705-213006P 151100*1032*1285PE

400*600400*60034040-10016-642706P 301623*1736*1615PE

500*750500*75042550-10040-1102686P 551920*1850*1920PE

600*750600*750500150-20080-2402686P 552020*1850*1920PE

600*900600*90050065-16050-1602546P 552530*1900*2340PE

750*1060750*106063080-180110-3202458P 1102680*2380*2785PE

900*1200900*1200750100-200220-3802088P 1103470*2876*3330PE

1200*15001200*15001020150-350400-10001808P 160-2454850*3220*3680PE

1500*18001500*18001200220-350500-12001808P 280-3805160*3660*4248PEX

150*750150*75012018-488-253204P 151170*1575*1030PEX

250*750250*75021025-6013-353206P 221550*1730*1470PEX

250*1000250*100021025-6016-523306P 301580*2006*1390PEX

250*1200250*120021025-6020-613306P 371780*2214*1430PEX

300*1300300*130025020-9016-1053006P 552210*2320*1723Note: The

output will vary depending on factors such as different materials,

feeding force, etc.Detailed Ph

Related products about High Efficiency Mini Sand Making Crushing Crush Jaw Crusher Machine

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup