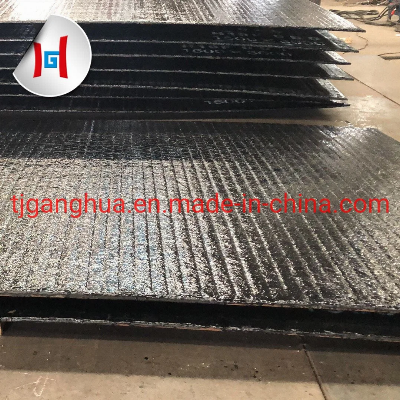

High impact wear resistant chromium carbide overlay plate

HRC60-65 Chrome Carbide Overlay Wear Plate are

manufactured by welding one or multiple wear resistant layers on

a medium or low carbon steel base plate.The overlay alloy has

a high amount of chromium carbide hard particles which makes

the plate have good wear and impact resistance. Overlay

thickness range: 3-25mmWear plate

size: 1500*3000, 1400*3000,1400*3400, 1400*3500,

2100*3500, customized.Chrome Carbide Overlay Wear Plate are

used to make many complex wear parts to be positioned in high wear

places.We have several equipment to transform our

plates: Eight sets of plasma cutting machine

, 6 bending machines and pressing machines,with high

processing capacity operated by engineers and technical experts, we

can provide wear plate cutting, bending, bolting, punching and

welding according to customer's drawings.1.Drilling HolesStraight

holes and Countersunk holes.2.Bolt embedded welding in the

backEmbedding the Pre-processed bolt in the back of wear

plate.3.BendingWear plate can be cold formed and made into curve or

cone.4.WeldingWear plate can be welded and assembled into kinds of

wear parts.Wear pipe, Elbow, Square to round transition We

also introduced in our factory automatic welding equipment for

pipes (internal and external) meeting the increasing demand for

small diameter wear pipes.Wear pipes1. Steel pipe with regular base

material + overlay, pipes are welded with our

automatic welding machine resulting in good shaped and flat surface

pipes.2. Bending the wear plate into round pipes3. Assembling the

wear plate into square pipesAutomatic welding, metallurgical

bonding, available to weld the maximum pipe diameter of 80mm and

maximum pipe length of 3000mm.Wear elbowWeld directly on the elbow

wallusing wear plate to make lobster back bendwear plate used to

make tube with round top and square bottomHigh impact wear

resistant chromium carbide overlay plate

HRC60-65 CharacteristicsQ235/Q345 base hardfaced high wear

resisting clad plate1, high wear resistanceCarbon content in the

chemical composition of the alloy layer of 4 ~ 6%, the

chromium content up to 25 ~ 30%, the microstructure of Cr7C3

carbide volume fraction of 45% or more, the macro hardness

HRC56-62, the hardness of chromium carbide is HV1400 ~ 1800,

higher than the hardness of sand quartz in HV800

~ 1200.Because the carbide into vertical distribution in the

direction of wear, even compared with the same composition and

hardness of casting alloy, wear-resisting performance is more than

double. 2, good resistance to impactThe ground floor of the

wear-resistant composite plate is low carbon steel or low

alloy.Ductile material such as stainless steel, and demonstrate the

superiority of bimetal, wear-resisting layer of abrasion resistance

of medium wear and substrate under medium load, thus has

a good resistance to impact.Can withstand conveying system

under high head hopper and other impact and abrasion. 3, good

heat resistanceWear-resisting layer is recommended to use under the

working condition of 600 ºC or less use, if adding vanadium alloy

layer, such as molybdenum alloy, can withstand the high temperature

of 800 ºC or less wear and tear.Recommended temperature is as

follows: ordinary carbon steel substrate recommended is not higher

than 380 ºC condition of use;Low alloy heat-resistant steel plate

(15 crmo, 12 cr1mov, etc.) recommended base plate is not higher

than 540 ºC condition of use;Heat resistant stainless steel

substrates recommend used at not higher than 800 ºC

condition. 4, good corrosion resistance, wear resistance

of composite steel plate containing high percentage of chromium

metal alloy layer, so have ability to rust and corrosion.Used for

coal cylinder and hopper, etc can be done to prevent caking

coal.High impact wear resistant chromium carbide overlay plate

HRC60-65 Specification as follows: Product NameChromium

carbide overlay hardfacing wear plate liner Base

PlateQ235/Q345.Hardfacing layerHigh chromium high carbide

overlay.Chemical CompositionC(%): 3.0-5.0 ,Cr(%):

25-40.MicrostructureThe carbide (Cr7C3) volume fraction on the

microstructure is above 50%.HardnessHRC58-65.Surface

TreatmentHardfacing,clading,coated.TechniqueHardfacing,open arc

welding,submerged arc welding.Wear ResistanceHigh wear

resistance,30 times higher than low carbon steel and 12

times than heat treated steel.Impact ResistanceMedium.Flatness

tolerance±3mm/m.Thickness toleranceUniform overlay thickness, with

tolerance within 0-0.5mm.Main

Thicknesses3+3,4+4, 5+56+4,6+5,6+6,6+88+4,8+5,8+6,8+7,8+810+4,10+5,10+6,10+7,10+8,10+9,10+10,10+2012+4,12+5,12+6,12+7,12+8,12+10,12+11,12+1214+6,14+8,14+10,16+6,16+8,16+1018+6,18+8,18+10,20+5,20+6,20+8,20+10,20+20,30+10,40+10Customized.Plate

SizeOpen arc welding wear plate:1400*3400mmSubmerged arc

welding wear plate:1400*3000mm,1400*3500mm,

2100*3500mm.Customized.Place of

OriginChina.ApplicationMining,Steel,Cement,Power,Port,etc.High

impact wear resistant chromium car

Related products about High impact wear resistant chromium carbide overlay plate HRC60-65

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup