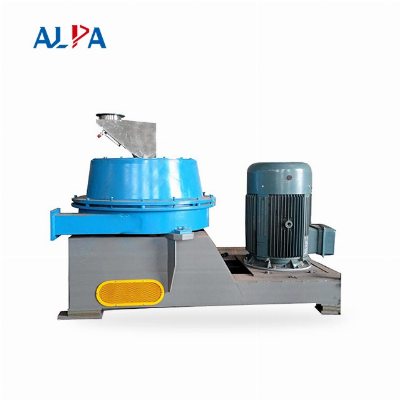

Turbo MillPowerful vortex flow field, instantly grinding and

coatingFEATURES AND ADVANTAGES The tapered rotor and stator

are adopted, and the gap between the rotor and the stator can be

adjusted; the powerful vortex flow field, the linear speed of the

rotor can reach 120 m/s, which is especially suitable for the

dispersion, reduction and crushing of agglomerated materials. The

material is impacted, sheared and rubbed at high speed between the

rotor and the stator to complete the grinding and coating

process. Available D50:1~250μmConic rotor and stator are

installed, product fineness and output can be controlled by

adjusting the gap between the rotor and the stator.The rotor and

the stator are made of special wear-resistant steel and thus have

long service life.The linear speed of grinding rotor can be up to

130m/s, high grinding effect.Large air volume and low grinding

temperature, suitable for sensitization of heat sensitive and

fibrous materials, uniform product size.Powerful eddy current flow

field, material is grinded instantly, material retention time in

the chamber is short, no temperature rise.Adjustable the gap

between grinding rotor and ring gear, to achieve different grinding

force.Suitable for depolymerizing nano and micron material.Alloy

material rotor, high-speed dynamic balance, up to 6 layers of

wear-resistant powder plate, guarantees excellent grinding

effect.Compact structure and small occupation. easy to disassemble

and cleanLower installation power, wide application, high

cost-performance.Grinding is in closed system, low dust and noise,

clean and environmentally friendly production process.PLC control

system, easy operation.Multi-purpose machine, can realize coating

and dispersing integration through external hot air source, full

coating, temperature controllable, free from environmental

influence, good coating effect.Can be used in series with

multi-stage classifiers to produce products with multiple sizes at

one time.Explosion-proof design can be selected to meet the

requirements of ultra-fine grinding processing of flammable and

explosive oxide materials.WORKING PRINCIPLECoating mechanism1. The

basic principle of coating: obtain the highest coating rate or

coating effect with the minimum coating material or cost;2. Surface

coating of mineral fillers, the main functions include dispersion,

viscosity reduction, filling, and interfacemechanics;3. The most

commonly used coating methods are: surface chemical coating method,

coated coating method, mechanical force chemicalcoating method;4.

The coating methods mainly include: coating mechanism, modifier,

coating process and equipment, process control, product testing and

evaluation;5. If the purpose, method and modifier of the coating

are different, the process and equipment are also different.Basic

Process Requirements1. The modifier uses dilution, emulsification,

spray addition and other measures to improve the dispersion,

preferably continuous spray or drip with the continuous feeding of

the powder;2. Precision metering and uniform feeding of modifier

and materials to ensure the instantaneous precision of the ratio of

the two, to achieve uniform and firm coating of the modifier on the

surface of the powder, good controllability and stable product

quality;3. The regulation of the temperature and time of the system

should meet the requirements of the coating mechanism or the

modifier on the process conditions, and ensure the sufficiency of

the coating reaction;4. the equipment operating conditions are

good;5. The use of auxiliary equipment (deagglomerator or

classifier), environmental factors (temperature, humidity),

etc.Advantages when used as coating modificationTECHNICAL

PARAMETERS Model / Production Capacity / Particle

SizeCUM-P200CUM-P400CUM-P630CUM-P800D97:5um300kg/h700kg/h1800kg/h3000kg/hD97:10um500kg/h1300kg/h3300kg/h5800kg/hD97:15um600kg/h1600kg/h4000kg/h7200kg/h

Note: The above data is exemplified by the coating of calcium

carbonate GCC. Related Engineering CaseShandong ALPA Powder

Technology Co., Ltd.(abbreviation: ALPA / Equity Code: 171033)

THE WORLD'S LEADING SUPPLIER OFULTRA-FINE POWDER

SOLUTIONSALPA was founded in 1999.Focus on ultra-fine ultra-pure

crushing and classifying research, powder shape control, powder

surface modification, and system integration of powder engineering

equipment.In the fields of ultrafine grinding and classification in

the pharmaceutical, food, chemical, mineral, new materials, solid

waste treatment and other industries, ALPA has mature and fully

customized solutions and helps you design the ideal system to meet

your needs. Certification AuthorityALPA is one of the

earliest companies in the industry that passed the ISO9001 quality

management system authority certification. At the same time, ALPA

has free import and export rights, and has obtained CE

certification for export to the European Union and GOST

certification for export to Russia. The machine design used in the

medical industry fully

Related products about Powder Quartz Ultrafine Grinding Powder Coating and Surface Modification

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup