The cement grinding plant mainly used in crushing and preheating of

clinkers, and grinding and packaging of cement. And it is mainly

applied to deal with industrial solid wastes like slag, coal ash,

coal gangues, and so on. Therefore, it contributes great to the

environment protection industry.Our cement grinding plant has the

features of simple technological process, easy operation, low

investment, electricity saving, environmental friendliness, etc.

And various admixtures can also be used in this plant.Here in

Jiangsu Pengfei Group Co., Ltd, one-stop service is available,

including engineering design, construction, related equipment,

assembly and debugging, technical service, and general contracting

service. Besides, we have successfully finished many relevant

engineering projects, like the construction of cement grinding

plant with an annual output of 1-1.2 million tons, the building of

cement grinding plant with 0.5-0.6 million tons' annual output, the

construction of 0.2-0.3 million tons' annual output cement plant,

and the building of plant with 0.1 million tons' annual

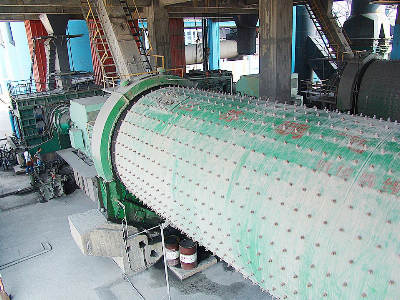

output.1,000,000Tons/Year Cement Grinding Plant: In this

1,000,000t/y cement grinding plant, clinker and slag are ground

separately. PFG120-50 rolling machine and Φ3.2m×13m cement mill are

used in clinker ginding. Φ3.2m×13m ginding machine and

high-efficiency powder separator are used in slag grinding.This

plant features are high quality, high productivity and low

consumption.Process Flow Design of 1,000,000Tons/Year Cement

Grinding Plant: 1. Designing of Clinker Grinding Production

LineAfter gypsum, clinker and limestone are measured by the belt

weigher, they will be mixed together in accordance with particular

proportions, and then sent to the stable weighing warehouse. During

this process, magnetic metals are removed by the iron remover from

these materials. Then mixed materials will be sent into the rolling

machine to be crushed. After crushed, they will be sent to the

powder separator, in which coarse powder will be sent back to the

griding mill while the fine one will be sent to the elevator for

finished products. Finally, they will be sent to finished product

storage. Meanwhile, dusty gas from the grinding mill will be

purified by the environmental protection equipment before

discharged into the atmosphere.2. Design of Slag Grinding

Production LineGypsum, dry slag and pulverized coal are measured by

the belt weigher before mixed together according to particular

proportions. Mixed materials will be sent to the mill for grinding,

and during this process, iron remover is employed to remove

magnetic metals in these materials. After grinded, fine powder will

be sent to high-efficeint powder separator, while coarse powder

will be sent back to the grinding mill. Finished cement will be

collected by the air tank pulse bag filter, while the fine powder

will be sent to the storage for finished products through an

elevator. Dusty gases from the mill will be used as the first gas

to enter into the powder concentrator, which is followed by fresh

air. Finally, dusty gas will be purified by the air tank pulse bag

filter before discharged into the atmosphere.3. Design of Mixing

Fine Slag and Powder Clinker Besides the fineness of powder

clinker and fine slag in the grinding production line, accurate

measuring and even mixing also need to be paid much attention to.

That's why we choose to use the screw measurer as the measuring

device and the air slide as mixing device as well as conveying

device.As a professional manufacturer and supplier of cement

clinker grinding plant in China, Jiangsu Pengfei Group Co., Ltd can

also provide you with various other machines, such as rotary kiln,

lime rotary kiln, industrial kiln and furnace, grinding equipment,

crushing equipment, environmental protection equipment, cooling

equipment, drying equipment, compound fertilizer equipment, packing

machine, chemical equipment and electrical control system. Most of

our products have passed the certification of ISO9000 and CE, and

they have been quite popular among customers from as many as 60

countries and aeras such as Germany, Russia, Brazil,

Egypt, Japan, Bengal, Pakistan, India, Turkey, UAE,

Vietnam, South Africa, Mozambique, Ivory Coast, Columbia,

Bolivia, etc.If you need cement grinding plant, please don't

hesitate to contact us. /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Cement Roller Press and Ball Mill Combined Grinding System in Cement Plant

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup