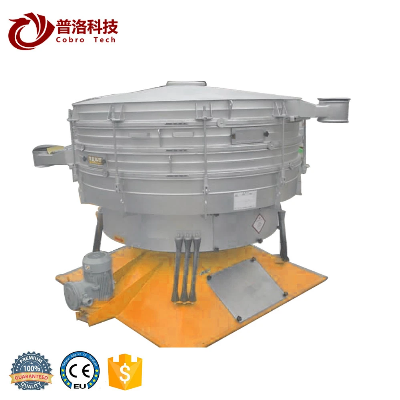

Product DescriptionDiameter 2000mm high accuracy large capacity PVC

resin tumbler screener PLYS series tumbler screen is used

for the treatment of valuable powders, pellets and granules.For

applications in pharmacy, food and fine chemicals produces tumbler

and vibration screening machine according to GMP.Technical

and benefits.- Screening efficiency up to 99%- No particle

destruction in sensitive products- High screening quality results

in higher revenues for graded products- Higher specific screen load

as compared to vibration systems- Stable screen motion even under

full load- Product specific mesh cleaning systems- Quick access to

the screen inserts- Modular design permits various machine

modifications- Dust tight, gas tight as option- Low-noise, easy to

maintainProduct Application1.Chemical industry: resin, pigment,

industrial medicine, cosmetic, coatings, medicine powder,

granules,palm oil.2.Food industry: sugar powder, starch, salt,

rice, milk powder, egg powder, sauce, syrup.3. Metallurgy, Mining

industry: aluminum powder, copper powder, ore alloy powder, welding

rod powder.4. Medical industry: all kinds of medicine5. Waste

treatment: disposed oil, disposed water, disposed dye waste water,

active carbon.Main feature of tumbler screening machine1) Simple

structure ,easy in installation and maintation. 2) Adopting

advanced world famous brand components in bearing parts ,electric

parts and operation parts. 3) Up to five decks incorporated in one

machine. 4) Whole sealed design,no pollution. 5) Apply a linker to

connect with the bucket elevator,air conveyor ,which can directly

inline with mixing machine or pulverizer. Product

Parameters ModelPLYS600PLYS1000PLYS1200PLYS1600PLYS1800PLYS2000PLYS2200Diameter(mm)600100012001600180020002200Screen

area(M2)0.210.660.981.812.84.15.3Screen

inclination1-51-53-5001-51-51-51-5Power(kw)0.551.52.2445.55.5Please

read this before you choose the suitable tumbler screening

machine.1.Please review your material properites: bulk density,

water content, granule size range, 2.Required data: The result you

wanna get by this machine, output per hour, mesh size and

screen deck number . 3.Power supply: if you are not clear on it,

please consult your electric staff to get the clear idea on it, if

your power supply is not right to this machine, motor will be

burned down. 4.Construction material: Stainless steel 304 for

material contact parts and carbon steel for other parts. If there

is special need, free to advise. There are multi option for you.

Company Profile Certifications FAQ /* March

10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Vibrating Sieving Separator Swing Machine Food Powder Sifting Machine Tumbler Screener Round Gyratory Sifter

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup