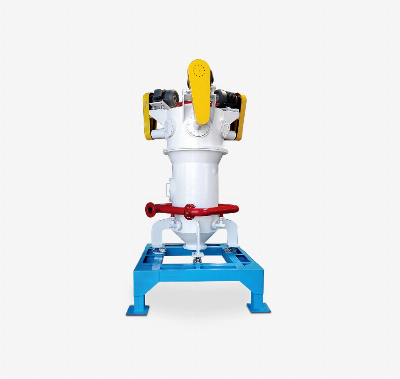

S-MQW Steam Jet MillWidely used in non-metallic minerals, chemical,

industrial solid waste and other industries. Working

Principle & Advantages Steam Jet Mill(Steam kinetic energy

mill) Upgraded by conventional jet mill, adopts unique

high-temperature mechanical sealing technology, cooling technology,

high-temperature steam as grinding kinetic energy medium, specially

designed Laval nozzle drive high-speed collision and grinding of

materials. The grinded material enters the forced vortex

classification, the qualified materials enter the heat preservation

collection system, and the coarse materials fall into the grinding

zone to continue the grinding, the whole process is completed under

the dry process. Available particle size D50:0.5-10μmNano

particle size is available.Steam of working pressure 8-40 bar and

temperature 230ºC-360ºC, both drying effectHigher speed of steam

results in higher kinetic energy, strong grinding force, high-speed

jet nozzle exit speed can reach 1020m / s, can produce finer

powderStronger grinding ability and energy, easy to achieve finer

powder.Compared with conventional jet mill, higher energy

efficiency, lower operating cost.The grinding process is completed

by the collision of the materials themselves., Fully self-grinding,

So The device is durable and the purity of products is high in

contrast.High speed and low viscosity, can achieve higher grinding

efficiency and classification accuracy, reduce over-grinding, and

obtain narrower particle size distribution.Good particle shape and

high activity.The classifying wheel separates the material

automatically with airflow, no coarse particles.Key parts like

inner liner, classifying wheel and nozzle are made of ceramic such

as aluminum oxide, zirconium oxide or silicon carbide, ensuring

non-contact with metal throughout the grinding for high purity of

the final product.Single or multi-classifying wheel are installed

horizontally.Speed of wheel is controlled by converter, particle

size can be adjusted freely.Grinding is in closed system, low dust

and noise, clean and environmentally friendly production

process.PLC control system, easy operation.Can be used for

ultra-fine processing of high viscosity products.The motor can be

connected with a belt to increase the speed and break through the

problem of high-speed motors without the well-known motor brand.Can

be used in series with multi-stage classifiers to produce products

with multiple sizes at one time.Weighing control system, high

precision, optional, high product stability.Optional

explosion-proof design, can also be upgraded to nitrogen

circulation system to meet the ultra-fine grinding processing

requirements of flammable and explosive oxide materials

Technical Parameters: Parameters(S

-MQL/W)Unit2000300040006000100001500020000Steam

Volumekg/h1000~20001500~30002000~40003000~60006000~1000010000~1500015000~20000Steam

Pressurebar5~405~405~405~405~405~405~40TemperatureºC260~360260~360260~360260~360260~360260~360260~360Output

Capacitykg/h400~1000600~1500800~20001200~30002000~50003000~80004000~10000Finenessμm0.5~100.5~120.5~120.5~140.5~140.5~160.5~16Note:

The production capacity is closely related to the particle size,

specific gravity, hardness, moisture and other indicators of the

raw materials. The above is only for selection

reference. Related Engineering Case:Who Choose Us:

37 world top 500 companies, 89

Chinese top 500 companies, 169 national key laboratories and

engineering technology

research centers have selected ALPA.

More than 3,000 customers have chosen usAbout

ALPA Powder ALPA is a world-renowned supplier of powder

processing systems, committed to traditional powder industry

development. For 20 years, focused on the research and development

of dry grinding, classification, powder shaping, surface

modification and provided systematic solutions. We provide

customized and international certified products: Jet Mill, Air

Classifying Mill, Classifier, Ball Mill and Classifying production

line, powder surface modification production line, etc.

Certification

AuthorityALPA is one of the earliest companies in the industry that

passed the ISO9001 quality management system authority

certification. At the same time, ALPA has free import and export

rights, and has obtained CE certification for export to the

European Union and GOST certification for export to Russia. The

machine design used in the medical industry fully meets the

requirements of GMP certification. Good After-sales ServiceOur

after-sales service team is always ready to diagnose and solve

problems for you.About Our Equipment

ALPA can provide dry ultrafine grinding

equipment suitable for various materialsImpact millHigh

efficiency, has two milling effects of impact and

Related products about Steam Jet Mill Industrial Solid Waste Powder Dry Processing Grinding Mill

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup