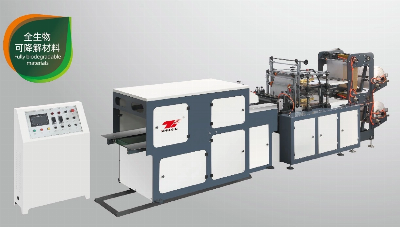

double layer glove making machine with automatic WASTE

REMOVEAutomatic double layer disposable plastic glove

machineIntroduction:After years of development and research, the

company integrates the advantages of similar products at home and

abroad. It is a full-automatic production line of plastic film

disposable gloves. In the production process, the finished products

and waste materials have been automatically separated, so that the

original products can be counted and sent out, so that workers can

easily bag and pack, with a speed of more than 400 per minute. It

has the advantages of long continuous working time, high output and

low labor force. The whole machine adopts microcomputer touch

screen control, three-phase hybrid motor to pull materials,

automatic counting can set the number of sheets at will. It can be

customized with various shapes, convenient for loading and

unloading.Purpose:The equipment can be transformed to produce

(ground) gloves and other related medical and health products. This

product is widely used in hotels, hotels, health care, family life,

paint protection, beauty salon, garden work, cleaning work, etc.

This machine is suitable for sealing and cutting gloves with high

density polyethylene (HDPE) and low density polyethylene (LDPE)

plastic film. It is an ideal machine for fast food restaurants such

as KFC.Technical parameterMaximum discharge diameter: 450mmLength

of gloves: 200-450mmWidth of gloves: 240-320mmFilm thickness:

0.008-0.02mmGlove making speed: 360 ~ 440 PCS / minMain engine

power: 2.2kwPower supply: 220V 60Hz / 380V 60HzMold 2 pairs

(copper)Body material: iron plate bodyDischarge rack (without edge

correction) gas account shaft: magnetic particle

controlConfiguration listHost part configuration listName, quantity

and originMain motor 2.2kW (with brake), 1 set, Dehli, Wuhu, Anhui,

ChinaDischarge motor 370W (AC motor) 2 sets, Dehli, Wuhu, Anhui,

China1 servo motor, Decheng, Wuxi, ChinaPLC computer (touch screen)

1 Decheng, Wuxi, ChinaDrive: 1 set, Decheng, Wuxi, China9 cylinders

Zhejiang Xingong Pneumatic Technology Co., LtdSolenoid valve 2

Ningbo Xiaxin pneumatic components factoryKey part bearing Harbin,

ChinaFrequency converter 2.2kW 1 HuifengDischarge frequency

converter 0.75KW 2 sets of HuifengElectrostatic eliminator 1

Wenzhou, China2 thermostats Shanghai Yatai, ChinaTwo discharging

photoelectricity devices, Yuyao, ChinaSwitch button Chint

ChinaShaft brake (magnetic powder) FZ 2.5kg 2 Ruian

HuaqiangConfiguration list of surplus material removerName,

quantity and originStep motor (20n) 2 Wuxi, ChinaConveyor motor: 1

Ruian DONGBANGTwo linear guideways, Ningbo, ZhejiangMain cylinder

Zhejiang Xingong Pneumatic Technology Co., LtdSolenoid valve Ningbo

Xiaxin pneumatic components factorySwitch button Chint ChinaCY-600

one layer short sleeve Glove making machinebelow is double

layer gove making cutting machine (speed double )Below is one layer

long sleeve glove making machine Company

ProfileWORKSHOPFAQ1.Q:Are you a factory or trading company

?A:We are a factory 2.Q:Where is your factory located

?How can I visit there ?A:Our factory is located in Ruian City

, Zhejiang Province ,ChinaAbout 40 minutes by plane from

shanghai (5 hours by train ) 3.Q:How is your after-sales

service ?A:We have been in this printing machine line of business

for more than many years ,We will send our professional engineer to

install and test machine .So our after-sales service is always

reliable. 4.Q:If your machines can print ?A :Our machines is

multifunction , do roll to roll printing , such as paper,

plastic film , woven bag , nonwoven .Surely , you

can offer your products, Let us confirm it .We will suggest you the

best project. 5 .Q:How does your factory do regarding the

quality control ?A:We are the technical factory, we put more time

on the quality control.Question: Are you Manufacture or Trading

Company? Answer:We are printing machines

manufacturer nearly 10years, we had established our own trading

company to expand our foreign market business, and provided our

customer better service.Question: Where is your factory located?

How can I visit there? Answer: Our factory is

located in Wenzhou City, Zhejiang province, China. The nearest air

port is Wenzhou airport, we can go Wenzhou airport pick

you. 6.Q: How does your factory do regarding quality

control?Answer: Most our machine mechanical parts are processed by

ourselves. So we can better control our quality from beginning.

Electrical Part we had cooperated with good foreign brand, such as

ABB, Yaskawa, Siemens, Airtac, NSK, Delta, Panasonic etc. And all

our machine will do running test before shipping. 7.Q:Do you

company provided foreign country machine installation

services?Answer: We have strong service team can provided all the

machines buy from our company foreign country installation service

and engineer training service. But buyer need provided the ticket,

food, hotel cost etc. 8.Q: How your company provided after

sales service?An

Related products about Double Layer Glove Making Machine with Waste Remove Device

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup