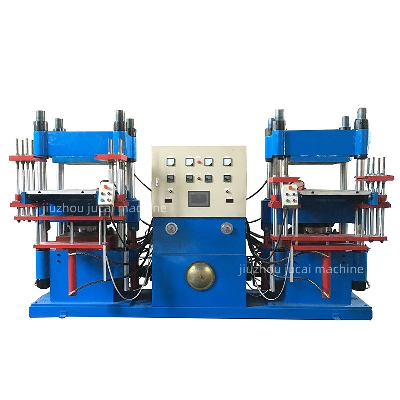

Vulcanizing Press, Rubber Vulcanizing Press, Vulcanizing Machine,

Hot Press Machine, Vulcanizer supplier Product

Description 1.Applicable for heating , vulcanizing and

solidifying various rubber moulding production2.PLC control & touch

screen3.Auto mold closing, air exhaust, temperature control, timing

setting4.Custom mold push out system5.Well-sealed hydraulic

cylinder with precise grinding and finishing6.Stable hydraulic

pressure station Machine Display Machine

Feature 1.The cylinder ( piston ) adopts the best seals

structure , with reasonable design and reliable function. The seals

part is good quality YX typepolyurethane seals (not rubber seal )

,which is oil resistant , aging resistant .Our machine adopts the

double seals structure , and seals part is easy change and

protect2.Automatic control : automatic mold closing , automatic

exhausting , automatic heating and keep stable temperature,

automatically timing for vulcanization , automatic alarming ,

automatic mold opening ,etc 3..The vulcanizing temperature can

be set and showed in the digital displan .4.Vulcanizing time can be

set in the PLC screen . If you want to heat and vulcanize for 1

minutes , just set it directly . When it reaches 1minutes ,machine

will alarm then machine will open the mold automatically5.Pillar is

made of high quality # 45 steel, The hardness , wear resistance and

abrasive resistance is high improved by quenching and

tempering6.The top beam and bottom plate form is welded with the

good quality Q-235A ductile iron .After welding , it is also

processed by the artificial vibration or high temperature

aging treatment , to eliminate the internal stress and avoid the

deformation7.plunger is made of LG-P cold hard alloy steel .

Surface of it owns high hardness and wear resistant.Depth of

chilled layer is 8-15mm , hardness is HRC 60-70 , making the

plunger own long life time8.Mainly hdralic spare parts are imported

from Taiwan , not our local brand Product

Parameters model/XLB-D0.25MNXLB-D0.5MNXLB-D0.8MNXLB-D1.0MNXLB-D1.0MNMold

closing force 0.250.50.81.01.0Heating plate

size 300*300350*350400*400450*450500*500500*500600*600450*450550*550Working

layer 1 / 21/ 2 1 / 21 / 21 / 2Plate

clearance 200200200200200Plunger

stroke200/400200/400200/400200 /400200 /400Plunger

diameter 152200250285300Unit area pressure of heating

plate

(kg/cm2)27.720.431.224.63222.249.333Heating Electrical Electrical Electrical Electrical Electrical Heating

temperature 300300300300300Control automatic automatic automatic automatic automatic Optional

control waySemi-automatic/ common automatic /PLC text type/ PLC+

touching screenGross

weight 900 1200/1350/14501550/175022002300

modelXLB-D1.0MNXLB-D1.2 MNXLB-D1.6 MNXLB-D2.0MNXLB-D2.5MNMold

closing force 1.01.21.6 MN2.02.5Heating plate

size 600*600700*700750*750800*8001000*1000Working layer 1

/ 21/ 2 1 / 21 / 21 / 2Plate

clearance 200200200200200Plunger

stroke200/400200/400200/400200 /400200 /400Plunger

diameter 300320360400450Unit area pressure of heating

plate

(kg/cm2)27.724.52531.2525Heating Electrical Electrical Electrical Electrical Electrical Heating

temperature 300300300300300Control automatic automatic automatic automatic automatic Optional

control waySemi-automatic/ common automatic /PLC text type/ PLC+

touching screen Company Profile 1.Are your company a

trading one or a factory?Factory + trade (integration), 30 years

focusing on rubber machine design and production .OEM is also

acceptable for us.2.How to choose the most suitable products?Our

professional team will give you the best suggestion as long as you

tell us what kind of product you need to do and the required

specification.3.Do you accept customization service?Yes, of course,

we can not only offer standard machines, but also customized

machines according to your request. Don't hesitate to tell us your

requirement, we will try our best to meet your needs.4.How about

your warranty?Generally, our warranty is one year. Within the

warranty period, we can offer technique support and part parts

change,necessarily, our engineers may go to your place for better

service.5.How about the packing for machine, is it safely protected

during transportation?Our machine is packed by standard export

wooden box, it won't be damaged. We've delivered many testing

machines abroad by sea or by air without damage.6.What is the order

process?Inquiry - quotation - communication - order confirming -

deposit payment - production - testing and debugging - balance

payment -packing - delivery - customer receiving - after

service. /* March 10, 2023 17:59:20 */!function(){function

s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Vulcanizing Press, Rubber Vulcanizing Press, Vulcanizing Machine, Hot Press Machine, Vulcanizer Supplier

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup