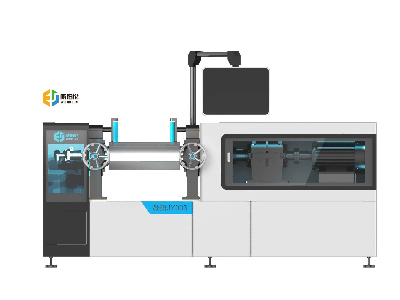

Professional Making Machine Two Roll Open Mixing Mill with

Emergency BrakeProduct Parameters NameSmall Open Mixing

MillTemperature rangeNormal temperature - 260 ºCTemperature

controllerLED digital display, key setting inputHeating

methodElectric heating tubeRevolution ratio1:1.27Speed0-35r/min

adjustableRoller size200*L590mm(optional)Roller spacing0.1-10mm

AdjustableSafety protectionSafety devices such as pull rod

emergency stop and knee top

reverseVolume2000*1000*1500(W*D*H)mmSourceAC380V,21A,Three phase

five wireWeight2000kgProduct DescriptionFeature 1. The core

technology and main components are from Taiwan; 2. The electronic

control part adopts imported electrical components, which are

convenient to operate and stable in performance; 3. The distance

adjustment method is optional for manual distance

adjustment/electric distance adjustment; 4. The overall bottom

plate is easy to install, and the transmission mode is single shaft

output to ensure large torque. Imported bearings reduce friction

force to ensure power saving, low noise, and uniform and

controllable rubber thickness; 5. The roller is made of vanadium

titanium alloy chilled cast iron, with a hard and durable surface

The finishing of the inner cavity of the roller ensures rapid and

uniform cooling of the roller body; 6. The roller bearing is

a rolling bearing, and the lubrication method of the roller bearing

is grease; 7. The machine is equipped with an emergency brake. When

an emergency occurs, there are emergency switches at the four

corners to facilitate multi position braking and quick stop of the

machine. Pull the emergency switch to immediately brake the

machine, ensuring safety and reliability; 8. The transmission

system device adopts a hard tooth surface reducer with compact

structure, high transmission efficiency, low noise, and long

service life; 9. The machine is equipped with an overload

protection device to protect main parts from damage due to

overload. Company Profile Established in 1981 in

Taiwan, Webron has accumulated nearly 40 years of experience and

continuous research and innovation, with over 5000 customer

reputation certifications. Webron has become one of the world's

leading professional mixer manufacturers; In 2019, the company

invested in and built a new factory in Xiamen, Fujian Province. In

addition, the company launched a 100 year sustainable operation

plan, periodically injecting new talent cultivation, which enabled

the company to inherit its corporate culture, integrate its

professional technology with the times, and provide customers with

permanent cooperative suppliers. Xiamen Webron is a national

high-tech enterprise, a star enterprise in Fujian Province, and a

well-known innovative technology research and development

enterprise. It was registered in the Cross-Strait Equity Trading

Center in 2021, with the enterprise code of 867467; The

headquarters is located in the Tsinghua Strait Research Institute.

It is a 3A credit enterprise in China, a member unit of the

Mechanical Mold Branch of the China Rubber Industry Association, a

key recommended private enterprise in Fujian Province, and a member

unit of the Fujian Plastic Industry Association; Signed contracts

with 15 professors in the fields of polymer, metal, and ceramics,

has industry-university-research cooperation with multiple

universities, and has joint laboratories with universities; It is a

metal ceramic rubber plastic machinery technology enterprise

specializing in research and development, design, manufacturing and

sales, and after-sales maintenance services. Company Vision: Let

China's mixing technology synchronize with the world. Serving new

material enterprises such as polymer materials, graphene materials,

advanced ceramics, and powder metallurgy, our core products include

torque rheometers, rubber internal mixers, metal internal mixers,

ceramic internal mixers, internal mixing and granulation integrated

machines, open mills, twin screw extruders, and plate vulcanizers.

The company has successively passed the certification of ISO 9001,

intellectual property management system, and high-tech products. It

has strong production capacity and advanced technological

processing equipment, such as 10 five-axis CNC machining centers, 4

CNC lathes, 5 slow moving wire and other imported processing

equipment. The company has independent laboratories, and various

materials and experimental equipment are provided to customers for

visiting/testing formulas/proofing. The professional R&D and

design team can meet the special non-standard requirements of

customers and customize the model, which has been recognized and

praised by the majority of customers. Since its establishment,

Webron has worked hard, innovated, and made progress. The company

promises to produce high-quality products for you with specialized

technology, and to create higher value for you with high-tech

achievements! Xiamen Webron Technology Co., Ltd. is willing to work

with you to create a br

Related products about Professional Making Machine Two Roll Open Mixing Mill with Emergency Brake

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup