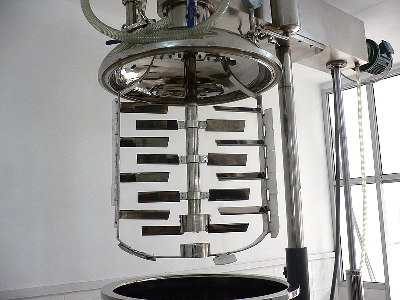

Hot sale stainless steel mixer Vacuum Emulsifying Mixer RHJ-U

vacuum eumulsifying mixerSuitable: cream,paste,

foundation,ointment, lotion, gel, conditioner, milk, sauce, etc

Capacity: 5~5000L Contact part: SUS304/316L (three jackets, contact

material parts adopt SUS316L, the other two layers adopt SUS304)

Homogenizer speed: 0~3600rpm Scraper speed: 0~80rpm Lifting:

hydraulic lifting system Heating: by steam/electrically Operation:

automatically (PLC)/manually Main CompositionThe vacuum emulsifying

mixture is mainly composed of water pot,oil pot,emulsify pot,vacuum

system,lifting system(optional),electric control system(PLC is

optional),operation platform,ect. Usage and Application FieldThe

product is mainly applied in such industries as daily chemical care

products,biopharmaceutical industry,food industry,paint and ink

,nanometer materials,petrochemical industry ,printing and dyeing

auxiliaries,pulp& paper,pesticide fertilizer

,plastic&rubber,electric and electronics,fine chemical

industry,ect,the emulsifying effect is more prominent for materials

of high base viscosity and high solid content. Performance &

FeaturesThe vacuum emulsifying produced by our company include many

varities. The homogenizing systems include upper homogenization,

lower homogenization,internal and external circulating

homogenization. The mixing systems include single-way

mixing,double-way mixing and helical ribbon mixing. The lifting

systems includes single-cylinder lifting and double-cylinder

lifting. Varies high quality products can be customized according

to customer 's requirements. The triple mixing adopts the imported

frequency converter for speed adjustment,which can meet different

technological demands. The homogenization structure made through.

German technology adopts the imported double-end mechanical seal

effect. The maximum emulsifying rotation speed can reach 4200 rpm

and the highest shearing fineness can reach 0.2-5um. The vacuum

defoaming can make the materials meet the requirement of being

aseptic . The vacuum material sucking is adopted, and especially

for the power materials,vacuum sucking can avoid dust. The

emulsifying pot lid can adopt lifting system ,easy to clean and the

cleaning effect is more obvious,the emulsifying pot can adopt tilt

discharge. The pot body is welded by imported three-layer stainless

steel plate. The tank body and the pipes adopt mirror

polishing,which fully conforms to GMP requirements. According to

technological requirements ,the tank body can heat or cool the

materials. The heating modes mainly include steam heating or

electric heating to ensure the control of the whole machine is more

stable,the electric appliances adopt imported configurations,so as

to fully meet the internal standards. Technical

ParameterModelCapacityHomogenizer motor(KW)Stir

motor(KW)Length(mm)Wide(mm)Height(mm)Total power(KW)limit

vacuum(Mpa) RHJ-G100100L2.8-41.527502700225013-0.09 RHJ-G200200L5.5-82.231003000250015-0.09 RHJ-G300300L5.5-82.235003350265018-0.085 RHJG500500L5.5-8438503600275022-0.08 RHJ-G10001000L9-115.542003850330028-0.08 RHJ-G20002000L11-145.545004050380034-0.08 RHJ-G30003000L15-187.548004300410040-0.08 Our

Services:1. We are a direct manufacturer and our priority is your

complete satisfaction. 2. Logo printing: We can print any logo as

per your requires on the case. 3. We take care of each order from

start to finish. All emails will be answered in 1 day 4. No matter

what's your order quantity, we will offer the same attention to our

quality and service 5. Delivery & lead time: All delivery methods

are ok, and our lead time is quite short. Usually, our lead time

around 7 days, depending on the quantity. 6. Packages: Available

for ploy bag and carton box Our advantageThe lowest price in the

same factory and service-oriented, an investment, a hundred

years to benefit our company is strong in technology, reliable

product quality, shelf, implementation of Three Guarantees, the

agency checked, large-tonnage available to your factory processing

our order! Our company:Guangzhou Li&Li Mechanical

Equipment Co, . Ltd. Is professional corporation that mainly

operates design, manufacture, installation and debugging of

cosmetic, pharmaceutical, chemical, food, etc. Equipments.

Enterprise strictly implements the ISO9001 standard management,

with strong technical force, complete detection equipment, advanced

process and complete product variety which including all kinds of

Reaction Kettle, agitator bath, storage tank, vacuum emulsifying

machine, conveyor, filling machine and non-standard equipments

process and manufacture; Electrical engineering, automatic-control

engineering, pipe design and equipment installation. /* March

10, 2023 17:59:20 */!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Tilting Hydraulic Lift Vacuum Emulsifying Mixer China Factory

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup