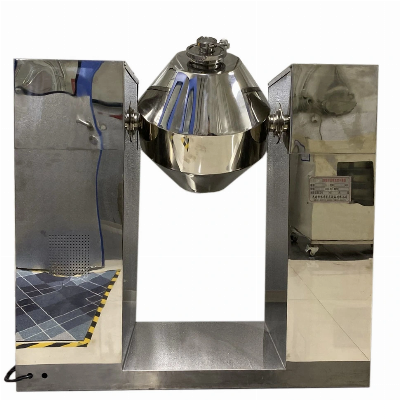

Products DescriptionDouble-Cone Vacuum DryerMaterial:SS304, SS316L,

Titanium, Hastelloy, PTFE linedApplication:mainly applicable for

drying all kinds of granular materials, such as

antibiotics,crystal, in the pharmaceutical, chemical and other

industries. Main CharacteristicsGood sealing performance:

concentric degree of shaft are controlled well, both ends use

mechanical sealing. Good rigidity: Both ends of the cone are welded

together with the cone vessel as a whole. It is not easy to be

deformed. Steady transmission: The whole unit is driven by the

electrical motor, reducer, big and small gears, which enables the

unit run more stably and reliably. Mounted with CIP and SIP

device.Design with SIP, CIP dedicated deviceThe cone angle is

designed as 60° which prevents materials from pilling during rotary

process, and avoids powder retention during discharging. The

special design of vacuum pipes and vacuum filter increase the

loading coefficient, which can even reach 65%.The device includes

three layers. The parts touching with materials Jacket in the

middle is for hot water circulation. To prevent stainless steel and

carbon steel from producing static corrosion, the jacket must be

made from stainless steel, and the outer layer uses fiberglass

cotton for heat preservation. Customer Site Technical

ParameterSpecification (L)Capacity (L)Drive power(kw)Rotate

speed(rpm/min)Host weight(kg)Diathermanous area

of condensator(m3)20≤100.556300350≤250.5564503100≤500.7568203..................18000≤9000302.220150200Our

Advantage Design / Calculation SoftwareCustom ServiceOur

Products for pharmaceutical and chemical industries1.

Multifunctional "Three in One" (filtering, washing and drying) 2.

Crystallizing Tank, Reaction Kettle3. Sterile double-cone dryer4.

Rake Vacuum Dryer /Paddle Vacuum Dryer5. Plate-fin Heat

ExchangerOur advantageSpecial Equipment: Pressure Equipment,

Equipment made of anti-corrosion materials, Sterile

EquipmentEquipment made of anti-corrosion materials includes:1.

Anti-corrosion lining plastic/ PTFE/ enamel, etc.Ti/HC22/Mone112.

Customized Design: Double-Cone in 20L-20m³Rake Dryer (with

mechanical seal) in 16 m³DN300-DN600 "Three in One"3.

Design/Calculation SoftwareScope of business1. On-site Inspection2.

Technical Innovation Plan for Equipment Technical Improvement Plan

for Equipment's Structure Optimization Fast and Effective Solution

to Equipment Malfunctions Highly Efficient and Precise On-site

Construction Service Commitment to a Deadline in Customization A

Full Range of long-term on-site technical maintenance service3.

Maintenance4. Technical Solutions5.On-site Testing and Training6.

Spare PartsCompany Profile /* March 10, 2023 17:59:20

*/!function(){function s(e,r){var

a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Related products about Industrial Continuous Double Cone Rotary Mixer for Pharma Powder Mixing and Drying

-

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

Waste Tyre Plastic Recycling Machinery Machine Tire Crusher Production Line Rubber Crumb Grinding Machine Equipment Tire Shredder

-

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

Stretch Plastic Blowing Pet Bottle Making Blow Molding Machine Bottles Stretch Automatic Pet Bottle Blowing Machine

-

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

Waste Plastic Pet Bottle, Water Bottle Flake, PP/HDPE/LDPE PE Film Jumbo Woven Bags Plastic Crusher Machine, Plastic Crushing Washing Recycling Machine

-

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

Type 2 Wall-Mounted Electric Car Charging Station 7kw /11 Kwelectric Vehicle Charging Station Home Wallbox AC EV Charger Single Phase or 3three Phase

-

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

G-View G12W Wholesale Auto Car LED Headlight Bulb High Power H13 H11 9005 H7 H4 Car LED Headlights LED Car Lights

-

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

New Design Porcelain Round Plates Dinner Set for Wedding and Banquet

-

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

China 2023 New Design Super Soft 100% Polyester Microfiber Knitted Oversized Decoration Hoodie Blanket

-

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup

Handmade Art Creative Materials Thickened White Paper Cup DIY Disposable Handmade Colored Paper Cup